Method and apparatus for controlling the laying of components of tyres on forming drums

A technology for forming rolls and components, applied in the field of controlling the laying of tire components on forming rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

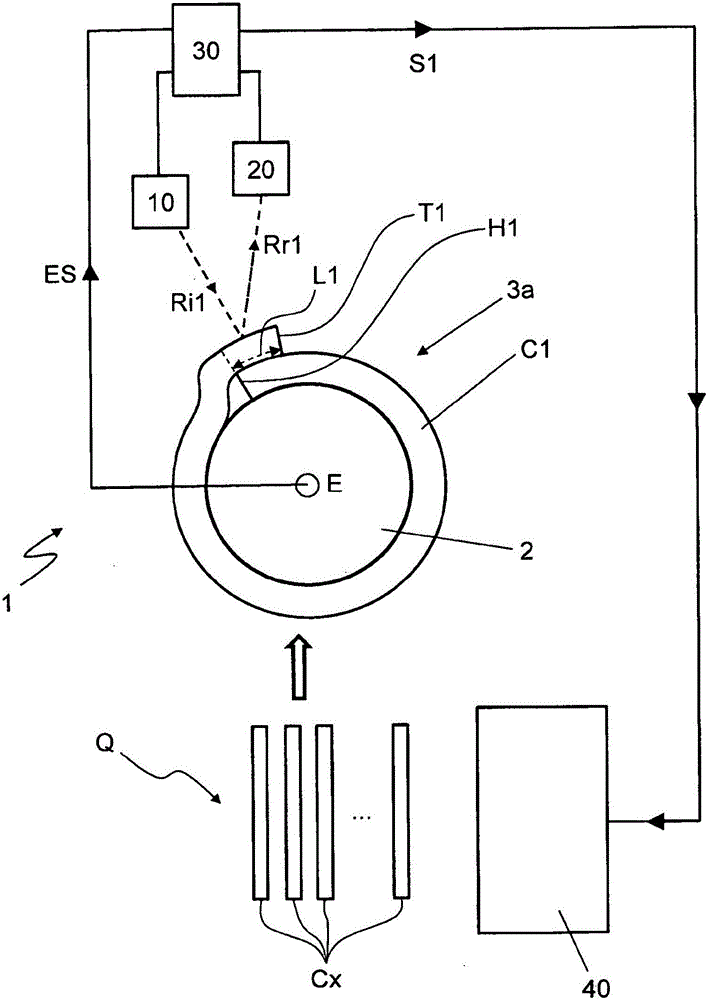

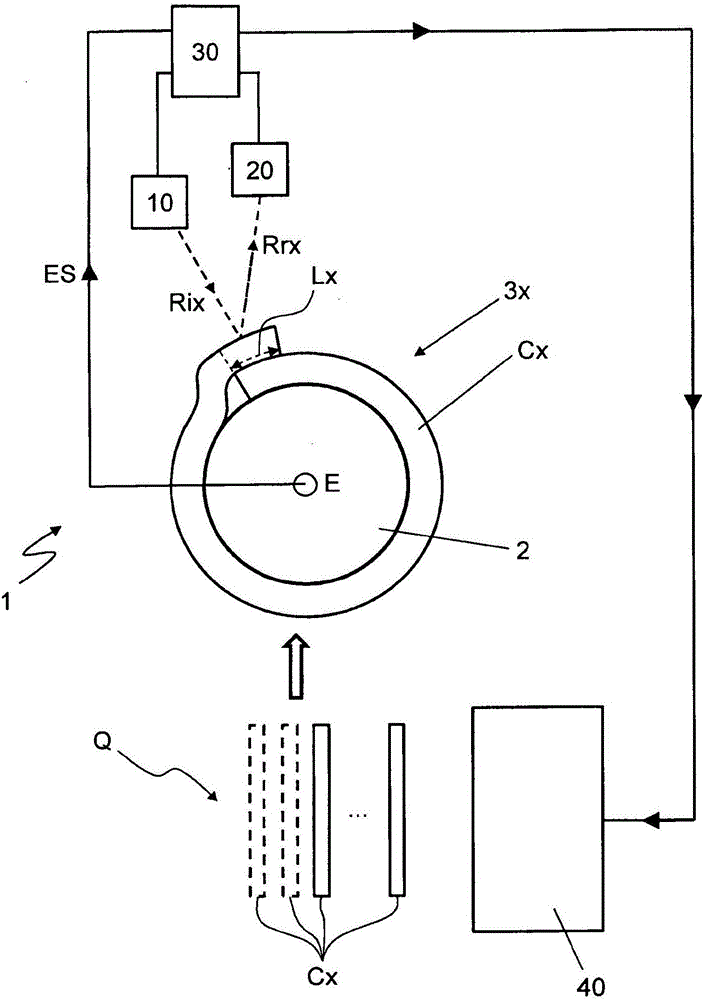

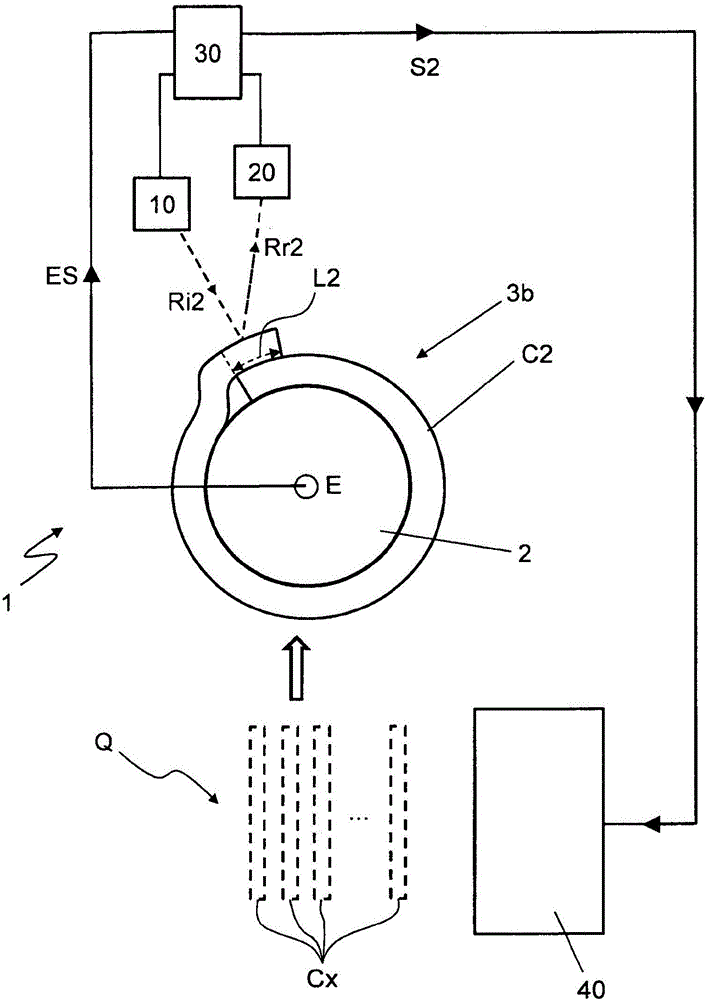

[0103] With reference to the accompanying drawings, figure 1 Overall there is shown a device for controlling the lay-up of tire components on forming rolls according to one aspect of the invention.

[0104] The device 1 can advantageously be used in a workshop for the production of tires for vehicle wheels, where the manufacture of each tire is carried out by sequentially laying up one or more components on corresponding forming rollers.

[0105] Each forming roll can receive components from a different delivery or preparation station. In an at least partially automated workshop (for example of the type shown in document WO2013 / 011396), the forming rolls can be moved by means of suitable equipment between different operating positions in which the forming rolls receive the Corresponding parts of the tire.

[0106] exist Figure 1-Figure 3 , block 40 represents, by way of example, a preparation station providing the components to be laid on the forming roll 2 .

[0107] In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com