Piece winding device

A technology of rolling film and sheet materials, which is applied in the field of film rolling devices, can solve the problems of decreased adhesion and heavy load of tape through, and achieve the effect that the adhesion will not decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, a film winding device to which the present invention is applied will be described in detail with reference to the drawings. In addition, this invention is not limited to the following example, It can change arbitrarily in the range which does not deviate from the summary of this invention.

[0058]

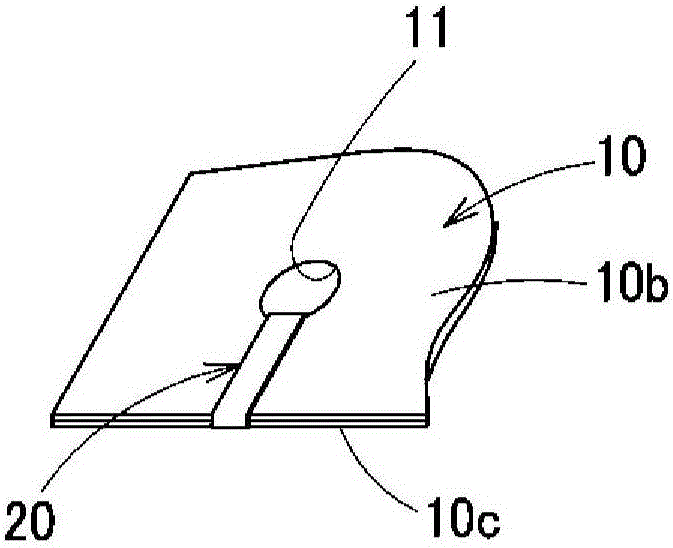

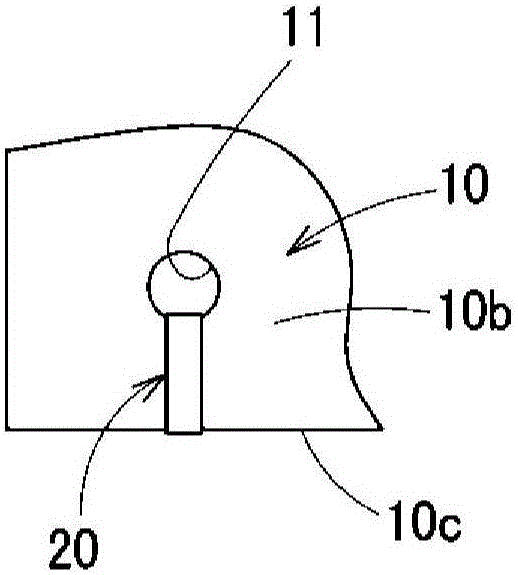

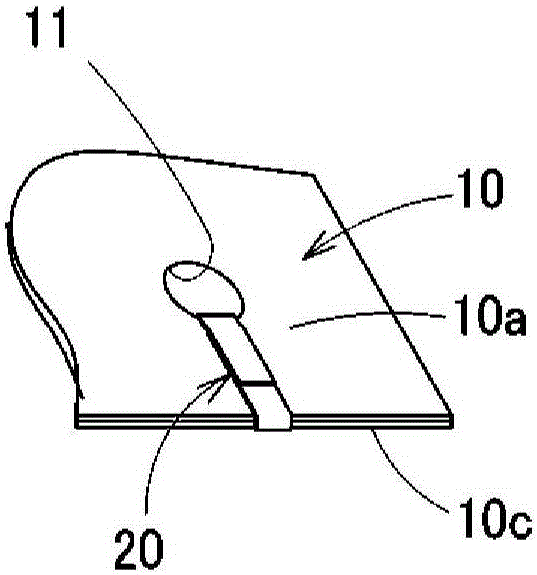

[0059] Such as Figure 1A ~ Figure 1D As shown, the sheet winding device 1 to which the present invention is applied, for example, winds a sheet 20 mounted on one side 10a of a sheet 10 having a hole 11 from one side 10a of the sheet 10 to the other side 10b, and winds the sheet 20 from the other side 10b of the sheet 10. One side 10 b is inserted into the hole 11 of the sheet 10 , whereby the sheet 20 is wound around the sheet 10 having the hole 11 .

[0060] Thus, the sheet winding device 1 can bind the sheets 10 through the sheets 20 by winding the sheets 20 around the sheets 10 having the holes 11 , and thus can be used as a binding device that binds the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com