Natural enzyme hydrolyzed cream and preparation method thereof

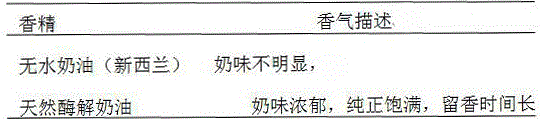

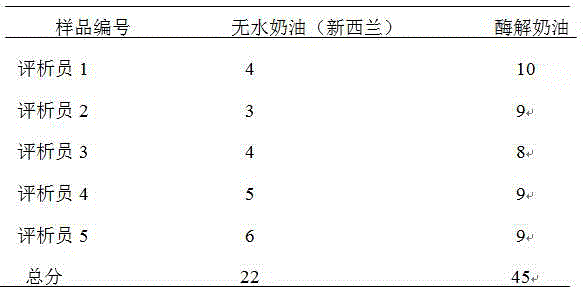

A natural enzyme and cream technology, applied in cream preparations, dairy products, applications, etc., can solve the problems of many raw materials, high flavor intensity of enzymatic hydrolysis products, low threshold, etc., and achieve internal quality improvement and unique milky flavor , the effect of natural aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of natural enzymatic cream is as follows:

[0040] A. Weigh 30kg of anhydrous butter and put it into the enzymolysis tank, and heat it to 50 degrees.

[0041] B. Weigh 53.13kg of distilled water, put it into the enzymolysis tank, and set the temperature to 50 degrees.

[0042] C. Weigh 1kg of lipase and 15.87kg of distilled water, mix and stir evenly before use.

[0043] D. When the solution temperature of the enzymolysis tank in step B is 50 degrees, add the lipase solution of step C, and set the temperature at 50 degrees.

[0044] E. Record the start time of the reaction. The process reaction is controlled within 4-5 hours. After 3 hours of reaction, sampling is performed every half hour, and the temperature is raised after passing the test.

[0045] F. Set the temperature at 95 degrees. When the temperature of the solution rises to 95 degrees, keep the temperature for 30 minutes and stop the reaction.

[0046] G. Stand still and take the enz...

Embodiment 2

[0048] The preparation method of natural enzymatic cream is as follows:

[0049] A. Weigh 50kg of anhydrous butter and put it into the enzymolysis tank, and heat it to 50 degrees.

[0050] B. Weigh 41.417kg of distilled water, put it into the enzymolysis tank, and set the temperature to 50 degrees.

[0051] C. Weigh 0.1kg of lipase and 8.483kg of distilled water, mix and stir evenly and set aside.

[0052] D. When the solution temperature of the enzymolysis tank in step B is 50 degrees, add the lipase solution of step C, and set the temperature at 50 degrees.

[0053] E. Record the start time of the reaction. The process reaction is controlled within 4-5 hours. After 3 hours of reaction, sampling is performed every half hour, and the temperature is raised after passing the test.

[0054] F. Set the temperature at 95 degrees. When the temperature of the solution rises to 95 degrees, keep the temperature for 30 minutes and stop the reaction.

[0055] G. Stand still and take t...

Embodiment 3

[0057] The preparation method of natural enzymatic cream is as follows:

[0058] A. Weigh 50kg of anhydrous butter and put it into the enzymolysis tank, and heat it to 50 degrees.

[0059] B. Weigh 39.69kg of distilled water, put it into the enzymolysis tank, and set the temperature to 50 degrees.

[0060] C. Weigh 1kg of lipase and 9.31kg of distilled water, mix and stir evenly before use.

[0061] D. When the solution temperature of the enzymolysis tank in step B is 50 degrees, add the lipase solution of step C, and set the temperature at 50 degrees.

[0062] E. Record the start time of the reaction. The process reaction is controlled within 4-5 hours. After 3 hours of reaction, sampling is performed every half hour, and the temperature is raised after passing the test.

[0063] F. Set the temperature at 95 degrees. When the temperature of the solution rises to 95 degrees, keep the temperature for 30 minutes and stop the reaction.

[0064] G. Stand still and take the enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com