Method for preparing dairy flavor spices by using compound lipase

A technology of compound lipase and lipase, applied in the field of dairy flavors and fragrances, can solve the problems of bad smell, less sweetness, roughness, etc., and achieve the effects of rich and natural milk flavor, improved taste, and permeable aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

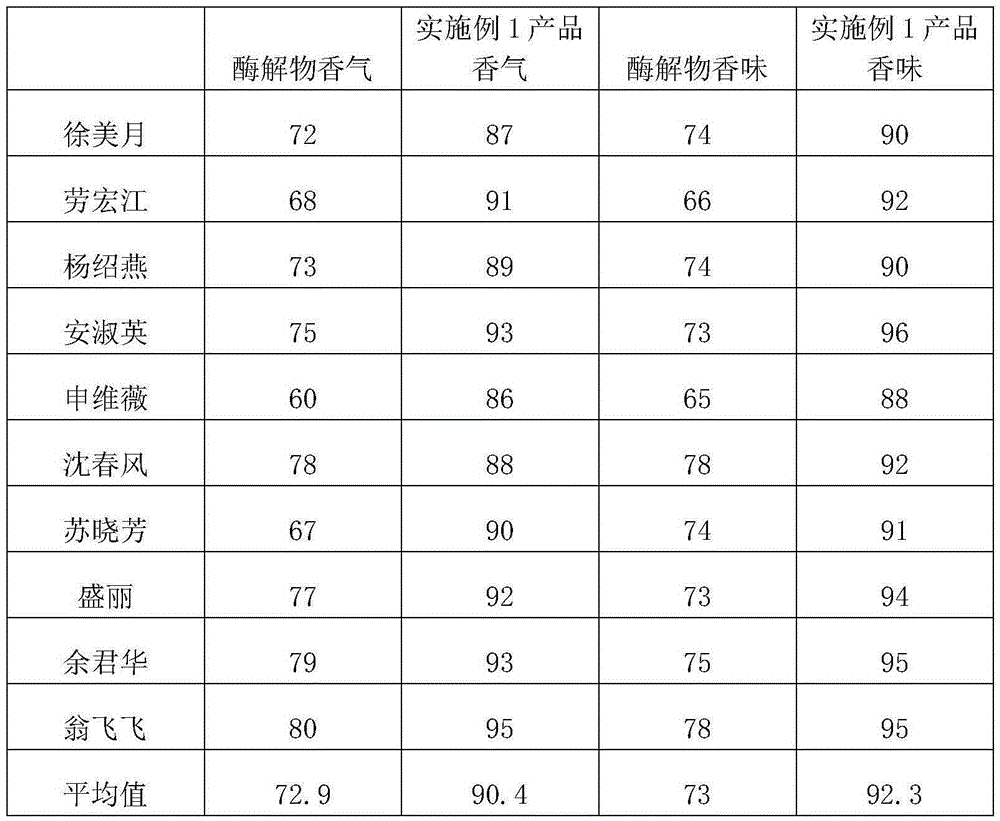

Examples

Embodiment 1

[0012] Use natural cream material, dilute with water at a ratio of 2:1, stir and emulsify, then pasteurize, control the temperature at 85℃, sterilize for 30 minutes, cool to 40℃, then add ethanol (30%) and compound lipase preparation For enzymatic hydrolysis, the main components of the compound lipase include pancreatin, Candida lipase, Pseudomonas lipase, phospholipase, and lipase. The weight ratio is pancreatin: Candida lipase: false Single cell bacteria lipase: Phospholipase: Lipase 20000=11:7:5:9:6, the addition amount of the compound lipase preparation is 2.3% of the weight of the raw material; the amount of ethanol added is 20% of the weight of the raw material; keep a constant temperature ( 50°C) 8 hours; the enzyme inactivation temperature is 85-90°C, and the enzyme inactivation time is 30 minutes. Then, after separation and purification, dairy flavor spices are prepared. It can endow the flavored product with natural milk fragrance without affecting the original milk ...

Embodiment 2

[0014] Use natural cream material, dilute with water at a ratio of 2:1, stir and emulsify, then pasteurize, control the temperature at 85℃, sterilize for 30 minutes, cool to 40℃, then add ethanol (95%) and compound lipase preparation For enzymatic hydrolysis, the main components of the compound lipase include pancreatin and Candida lipase, and the weight ratio is pancreatin: Candida lipase: Pseudomonas lipase=13:6:11, compound fat The amount of enzyme preparation added is 3.8% of the weight of the raw material; the amount of ethanol (95%) added is 11% of the weight of the raw material; continue to maintain a constant temperature (40°C) for 11 hours; the enzyme inactivation temperature is 85-90°C, and the enzyme inactivation time is 30 minutes . Then, after separation and purification, dairy flavor spices are prepared. It can endow the flavored product with natural milk fragrance without affecting the original milk fragrance of the product. It is an excellent natural food addi...

Embodiment 3

[0016] Use natural cream material, dilute with water in a ratio of 2:1, stir and emulsify, then pasteurize, control the temperature at 85℃, sterilize for 30 minutes, cool to 45℃, then add ethanol (50%) and compound lipase preparation For enzymatic hydrolysis, the main components of the compound lipase include a mixture of pancreatin, phospholipase, and lipase 20000, and the weight ratio is pancreatin: phospholipase: lipase 20000=9:7:8, and the added amount of the compound lipase preparation It is 2.3% of the weight of the raw material; the amount of ethanol added is 35% of the weight of the raw material; keep a constant temperature (45°C) for 6 hours; the enzyme inactivation temperature is 85-90°C, and the enzyme inactivation time is 30 minutes. Then, after separation and purification, dairy flavor spices are prepared. It can endow the flavored product with natural milk fragrance without affecting the original milk fragrance of the product. It is an excellent natural food addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com