Shoemaking production line press fitting-drying combined mechanism

A production line and integrated technology, which is applied in the direction of shoemaking machinery, footwear, and adhesive shoe parts, etc., can solve the problems of not achieving the best lamination effect, high operating cost, and failure to achieve heat interaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

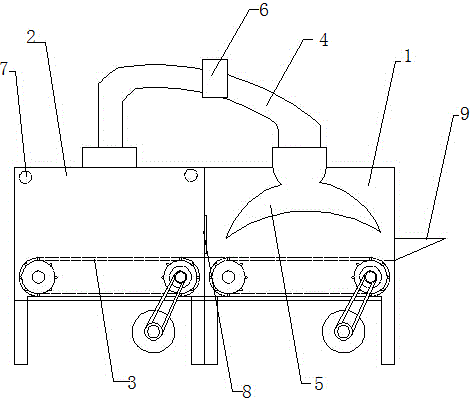

[0016] Such as figure 1 The one pressing and drying integrated mechanism of a shoemaking production line shown includes a pressing box 1 and a drying box 2; and a transmission mechanism 3 installed at the bottom of the pressing box 1 and drying box 2; the drying box 2 through the inflatable tube 4 and the press-fit inflatable bag 5 installed inside the press-fit box 1; the inflatable tube 4 is provided with an inflatable fan 6; the top of the drying box 2 is provided with an electric heating device 7; the electric heating The device 7 can be an electric heating wire or an infrared heating tube; a heat-insulating rain curtain 8 is arranged between the pressing box 1 and the drying box 2; an independent heating device is arranged inside the pressing box 1; One side of the case 1 is provided with a shoe upper introduction mechanism 9 .

Embodiment 2

[0018] The overall structure of the present invention is basically the same as that of Embodiment 1, wherein, no independent heating device is set up in the pressing box of this embodiment, and a heating hole is opened on the wall where the pressing box and the drying box are bonded; The heat inside is transferred to the inside of the press box.

[0019] The press-fitting and drying integrated mechanism of a shoe-making production line of the present invention makes the hot air inside the press-fitting box and drying box thermally circulated to ensure that the shoe body is evenly heated, and in addition, the inflatable bag is filled with hot air to ensure its press-fitting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com