A flotation column dosing system and dosing method

A dosing system and flotation column technology, used in flotation, solid separation and other directions, can solve the problems of unfavorable bubble mineralization, unsatisfactory recovery rate of flotation column, and high running tail, so as to improve the effective utilization rate and installation. Simple, Intensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

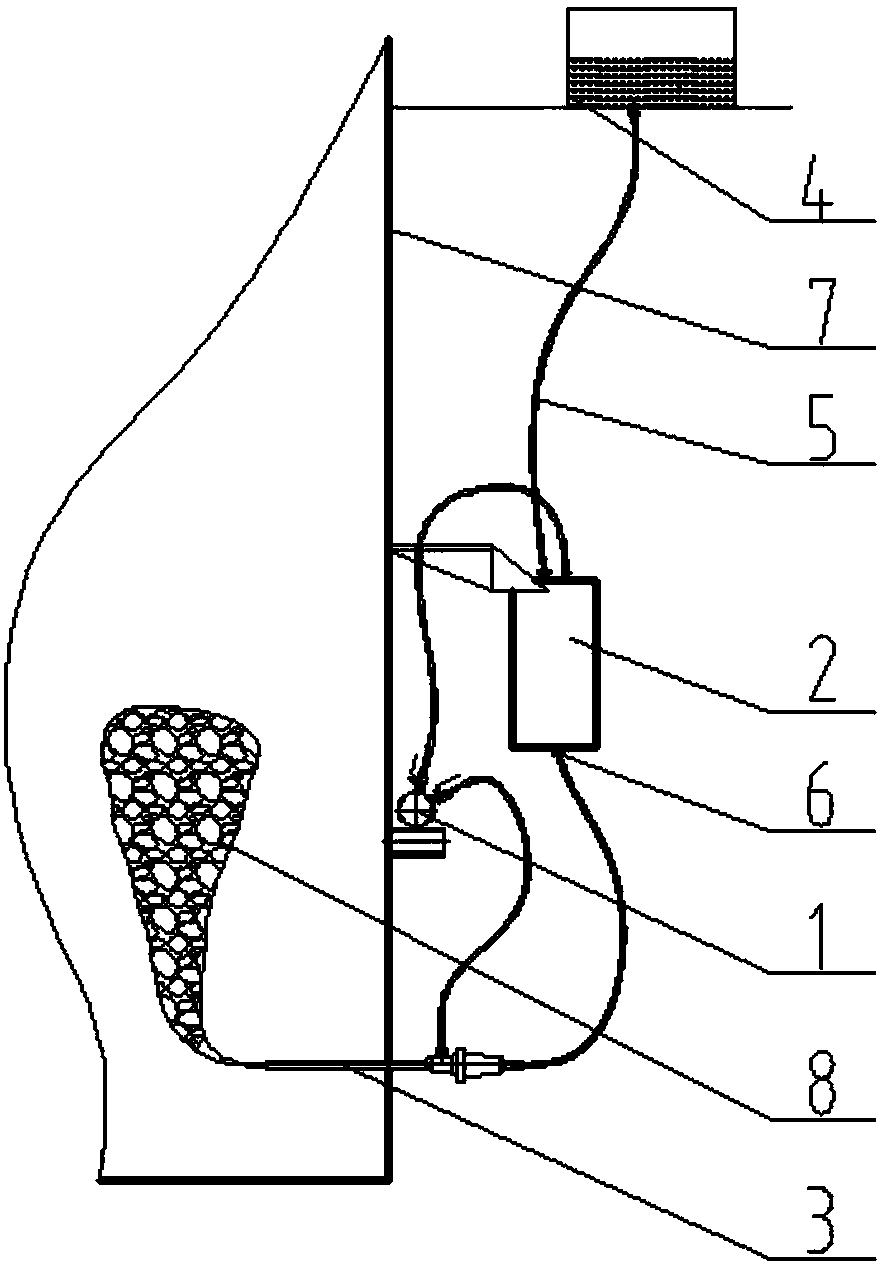

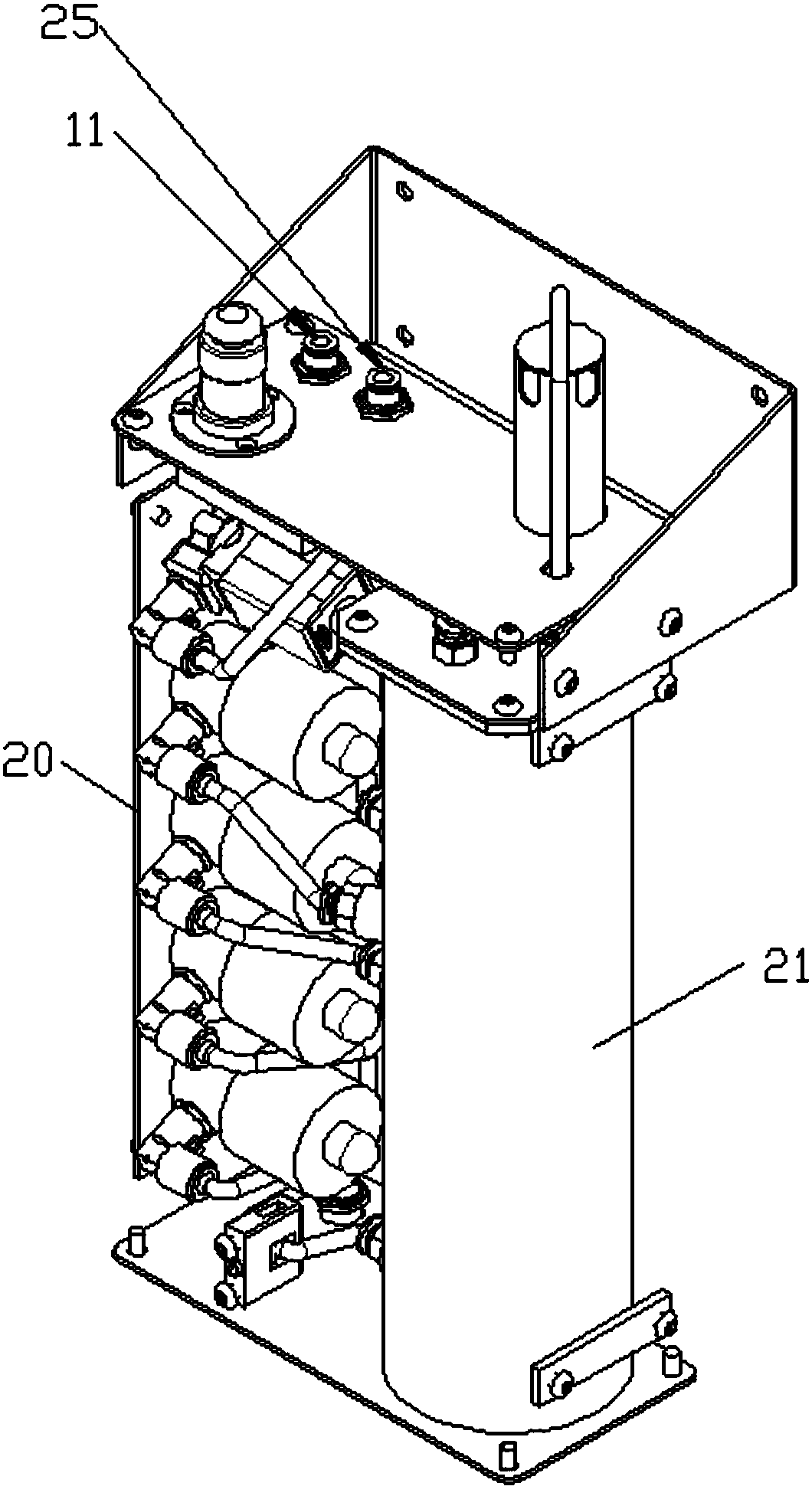

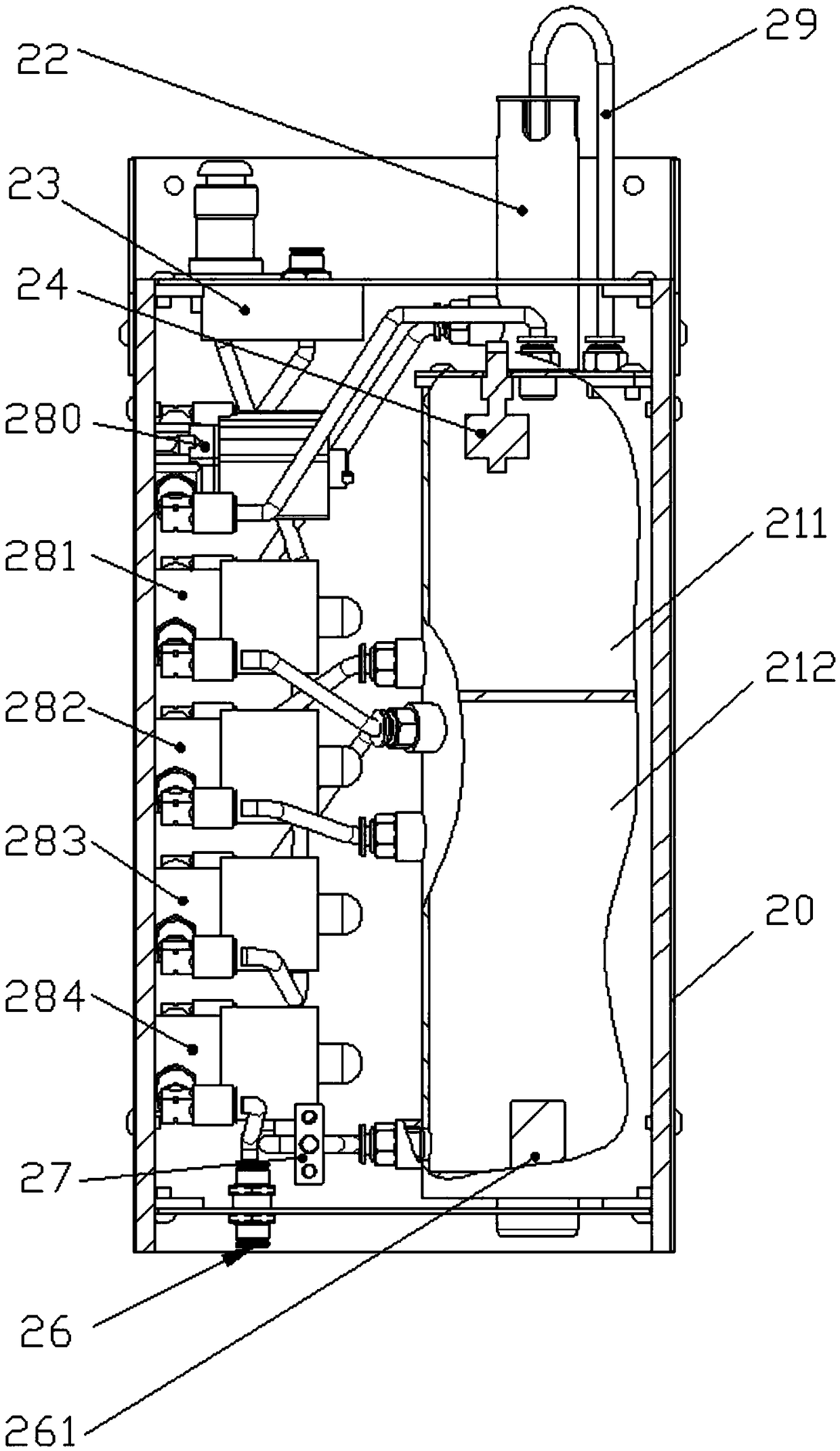

[0058] see Figure 1 to Figure 5 , the present invention provides a flotation column 7 dosing system, including a dosing controller 2 and a medicament atomization foamer 3, the dosing controller 2 is mounted on the outer wall of the flotation column 7, the The medicament atomizing foamer 3 is inserted in the flotation column 7; the drug dosing controller 2 and the medicament atomizing foamer 7 pass through the first high-pressure air inlet 11 and the second high-pressure air inlet 12 respectively It communicates with an external high-pressure air source 1 and is used to provide high-pressure air to the medicament dosing controller 2 and the medicament atomizing foamer 3 .

[0059] The medicine adding controller 2 is connected to the first medicine inlet 25 through the medicine feeding tube 5 and communicates with the external medicine box 4; The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com