Tool setting gauge for numerical control machine tool

A technology of CNC machine tool and tool setting instrument, which is applied in the direction of automatic control devices, metal processing machinery parts, metal processing, etc., can solve the problems of affecting the accuracy of tool setting, spring parts are easy to fail, etc., and achieve the effect of accurate reset and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

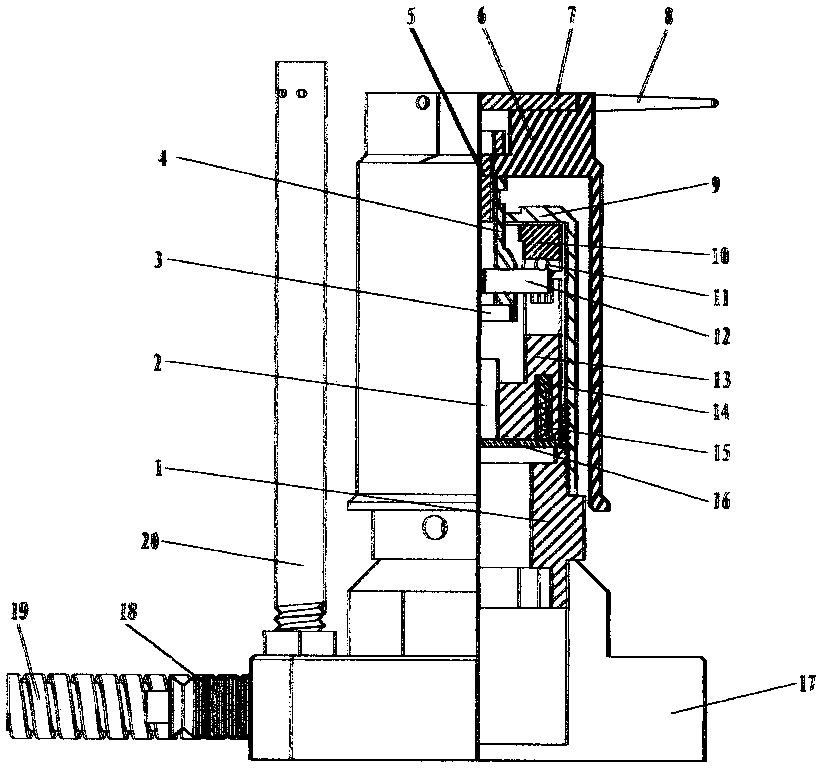

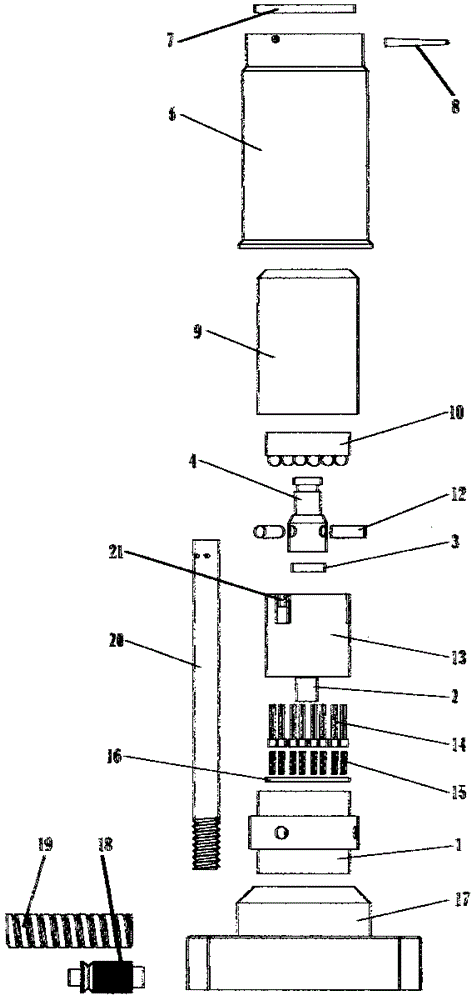

[0012] Such as figure 1 with figure 2 As shown, the CNC machine tool setting instrument consists of base 17, cable 19, gas circuit connector 18, lamp holder 1, gas column 20, magnetic core 2, probe 14, spring 15, probe holder 13, circuit board 16, magnetic Sheet 3, copper rod 12, copper rod holder 4, inner cover 9, tungsten steel sheet 7, stylus 8 and outer cover 6.

[0013] The lamp holder 1 is installed at the center of the upper part of the base 17, and the cable 19 and the gas joint 18 are installed on the side of the base 17. An upright air column 20 is installed next to the lamp holder 1 on the upper part of the base 17. The air connection 18 is in communication with the air column 20.

[0014] The probe holder 13 is installed on the lamp holder 1 and connected and fixed with the inner cover 9. The probe holder 13 has a cylindrical blind cavity inside, and three opening slots 20 are evenly distributed on the side walls of the blind cavity. The outer bottom plane of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com