FDM3D printer and automatic leveling printing method and system thereof

An automatic leveling and printer technology, which is applied in the direction of additive processing, etc., can solve the problems of insufficient algorithm accuracy, too many sensor points, and no smooth optimization, etc., to achieve excellent product quality, high processing efficiency, and accurate leveling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

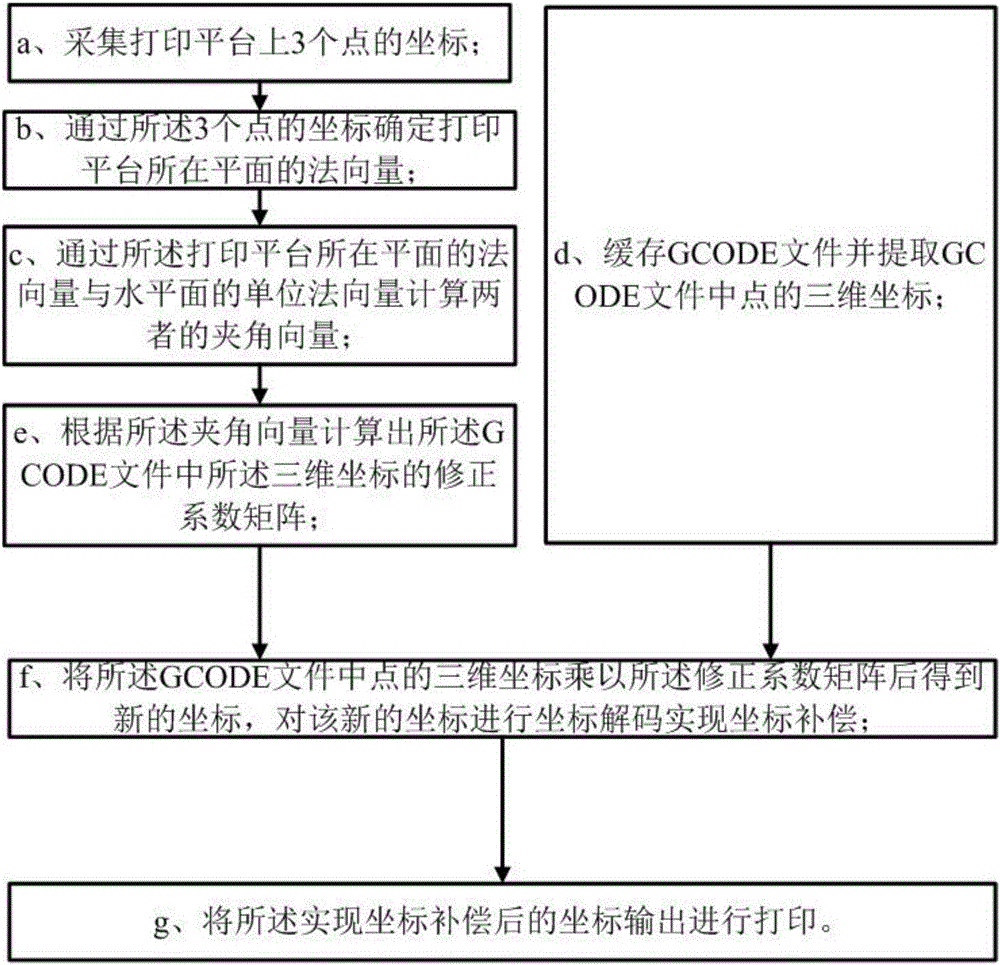

[0057] Such as Figure 1-3 As shown, this embodiment provides an automatic leveling printing method for FDM3D printers, including the following steps:

[0058] a. Collect the coordinates of 3 points on the printing platform;

[0059] b. Determine the normal vector of the plane where the printing platform is located by the coordinates of the three points;

[0060] c. Calculate the angle vector between the normal vector of the plane where the printing platform is located and the unit normal vector of the horizontal plane;

[0061] d, cache the GCODE file and extract the three-dimensional coordinates of the points in the GCODE file;

[0062] e. Calculate the correction coefficient matrix of the three-dimensional coordinates in the GCODE file according to the included angle vector;

[0063] f, multiplying the three-dimensional coordinates of the points in the GCODE file by the correction coefficient matrix to obtain new coordinates, and performing coordinate decoding on the new...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com