A flocculant with excellent dehydration of floc sediment

A sediment and dehydration technology, applied in the fields of flocculation/sedimentation water/sewage treatment, water pollutants, water/sewage treatment, etc. Large, excellent dehydration, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

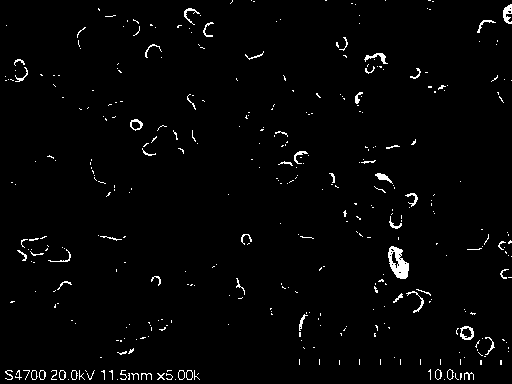

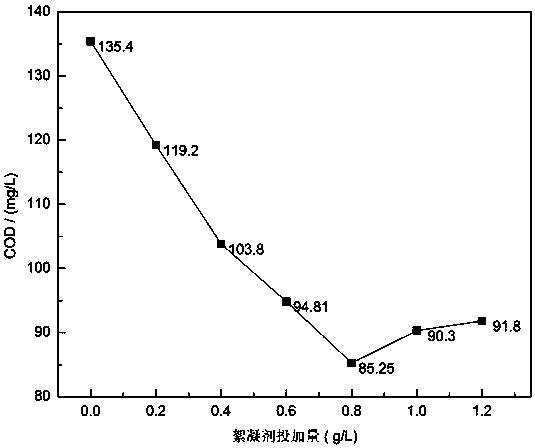

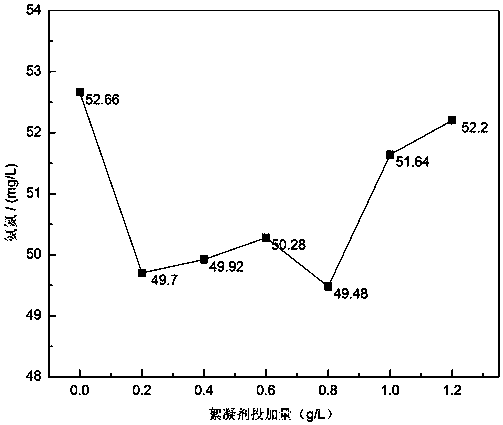

Image

Examples

Embodiment 1

[0025] Preparation of mixed solution A: Take the reaction vessel, add 250 ml of isopropanol, add 20 g of chitosan (industrial grade, deacetylation degree ≥ 80%) while stirring, keep stirring and heat to 80 ° C in a water bath, then add 80 Gram of 3-chloro-2-hydroxypropyltrimethylammonium chloride was stirred at 80° C. for 4 hours to obtain a mixed solution A.

[0026]Preparation of mixed solution B: take another reaction container, add 250 ml of isopropanol, then add 13 ml of tetraethyl orthosilicate while stirring, then add 26 ml of water (tap water), and add hydrochloric acid dropwise while stirring to adjust the pH of the solution to 4. Continue stirring at room temperature for 1 hour to obtain mixed solution B.

[0027] Preparation of flocculant: take the third reaction vessel, add 250 ml of mixed solution A and mixed solution B into the reaction vessel, then add 38 ml of 3mol / L aluminum nitrate aqueous solution and 25 ml of 5mol / L aluminum nitrate solution while stirring ...

Embodiment 2

[0032] Preparation of mixed liquid A: Take the reaction vessel, add 250 ml of isopropanol, add 37 g of chitosan (industrial grade, degree of deacetylation ≥ 80%) while stirring, keep stirring and heat to 90 ° C in a water bath, then add 262 Gram of 3-chloro-2-hydroxypropyltrimethylammonium chloride was stirred at 90°C for 6 hours to obtain a mixed solution A.

[0033] Preparation of mixed solution B: Take another reaction container, add 250 ml of isopropanol, then add 37 ml of tetraethyl orthosilicate while stirring, then add 74 ml of water (tap water), and add hydrochloric acid dropwise while stirring to adjust the pH of the solution to 3. Continue stirring at room temperature for 2 hours to obtain mixed solution B.

[0034] Preparation of flocculant: take the third reaction vessel, respectively take 167 ml of mixed solution A and 250 ml of mixed solution B into the reaction vessel, then add 33 ml of 3.5 mol / L aluminum nitrate aqueous solution and 25 ml of 5.7 mol / L while sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com