Automatic leakage detecting device of water heater or wall-hung stove and operating method thereof

A leak detection device, water heater technology, applied in the direction of measuring device, machine/structural component test, fluid tightness test, etc., can solve the problems of water heater quality influence, inability to judge, low accuracy, etc., and achieve supercharging speed Fast, easy to operate, ensuring accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

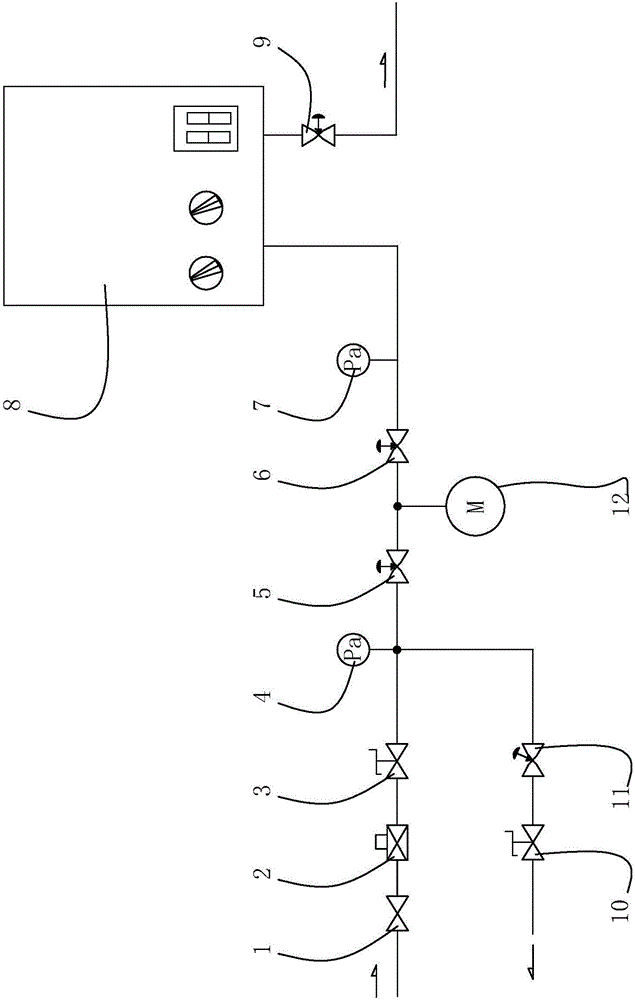

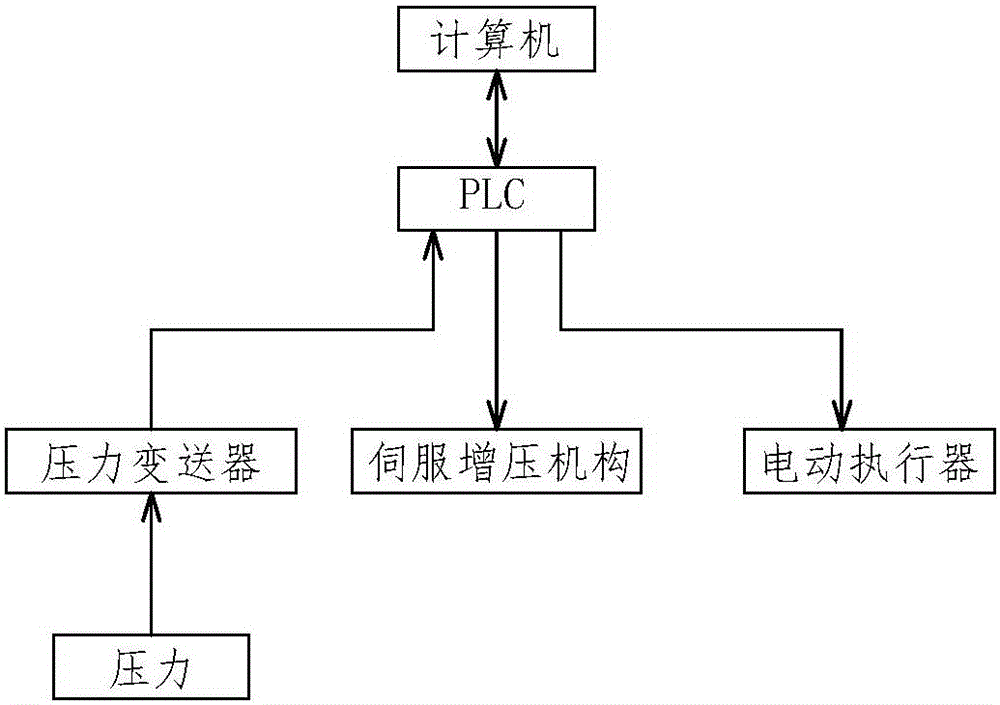

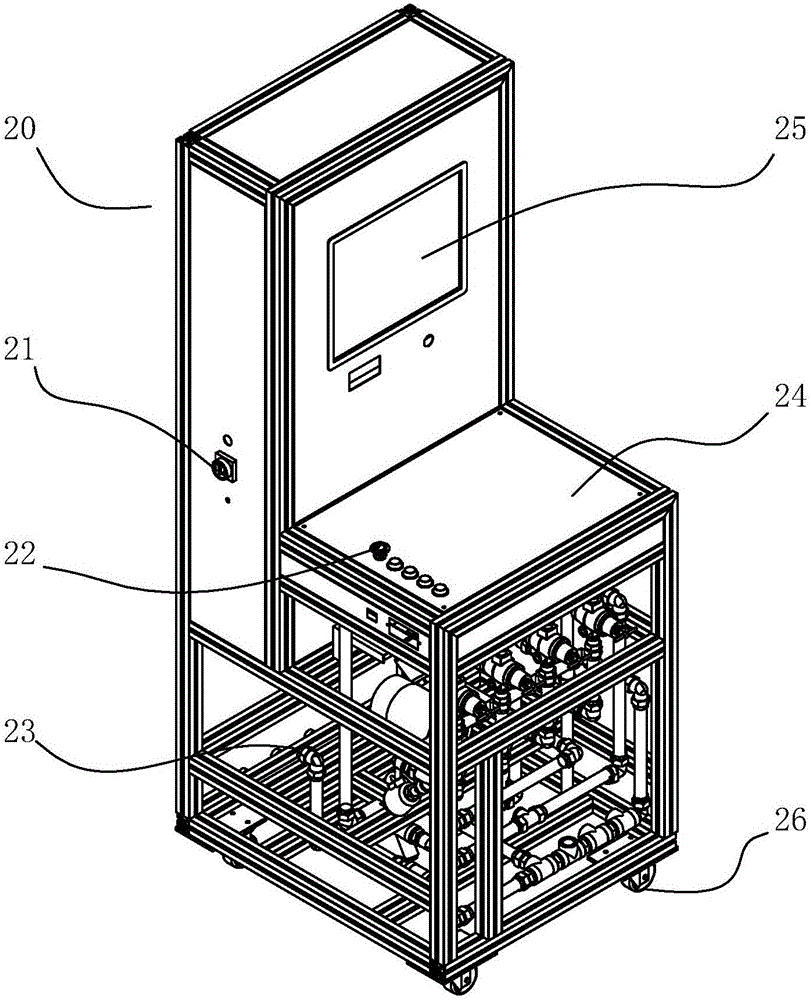

[0034] see Figure 1-Figure 4 , the automatic leak detection device for a water heater or a wall-hung boiler includes a water heater 8, the water inlet pipe of the water heater 8 is sequentially provided with a ball valve 1, a filter 2, a pressure regulating valve 3, a first waterway switch valve 5, a second waterway switch The valve 6 and the pressure transmitter 7, the water outlet pipe of the water heater 8 is provided with a water outlet valve 9; the pipeline between the pressure regulating valve 3 and the first waterway switch valve 5 is connected with the drain and pressure relief pipe, and a pressure is provided at the connection point Table 4, the drain pressure relief pipe is provided with a pressure relief valve 11 and a pressure relief pressure regulating valve 10 in sequence; the pipeline between the first waterway switch valve 5 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com