High pressure vessel peeping device

A high-pressure container and container body technology, which is applied in the field of high-pressure container peeping devices, can solve the problems of sudden change in stress and strain of the sight glass glass, uncontrollable pre-tightening force, unpredictable service life, etc., to solve the problem of uncontrollable pre-tightening Easy installation and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The high-pressure container peeping device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] Such as figure 1Various defects in the structure and sealing mechanism of the existing pressure vessel sight glass shown have been introduced in detail in the background art, and will not be repeated here.

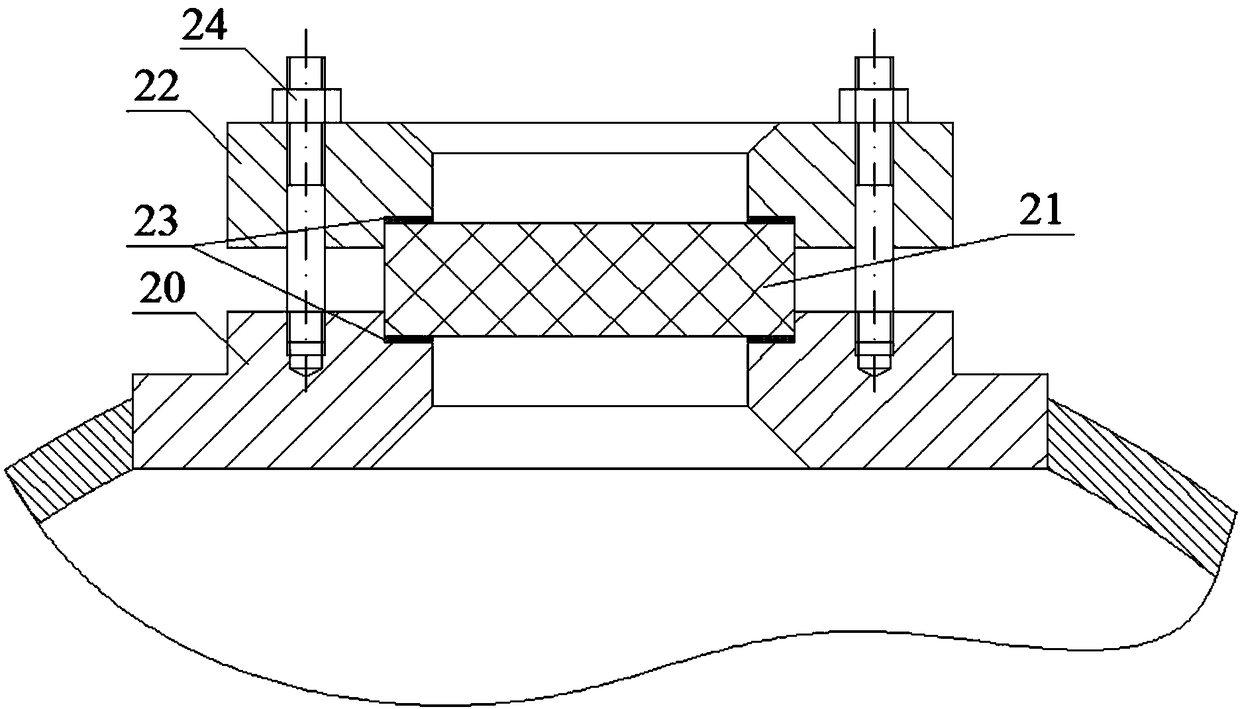

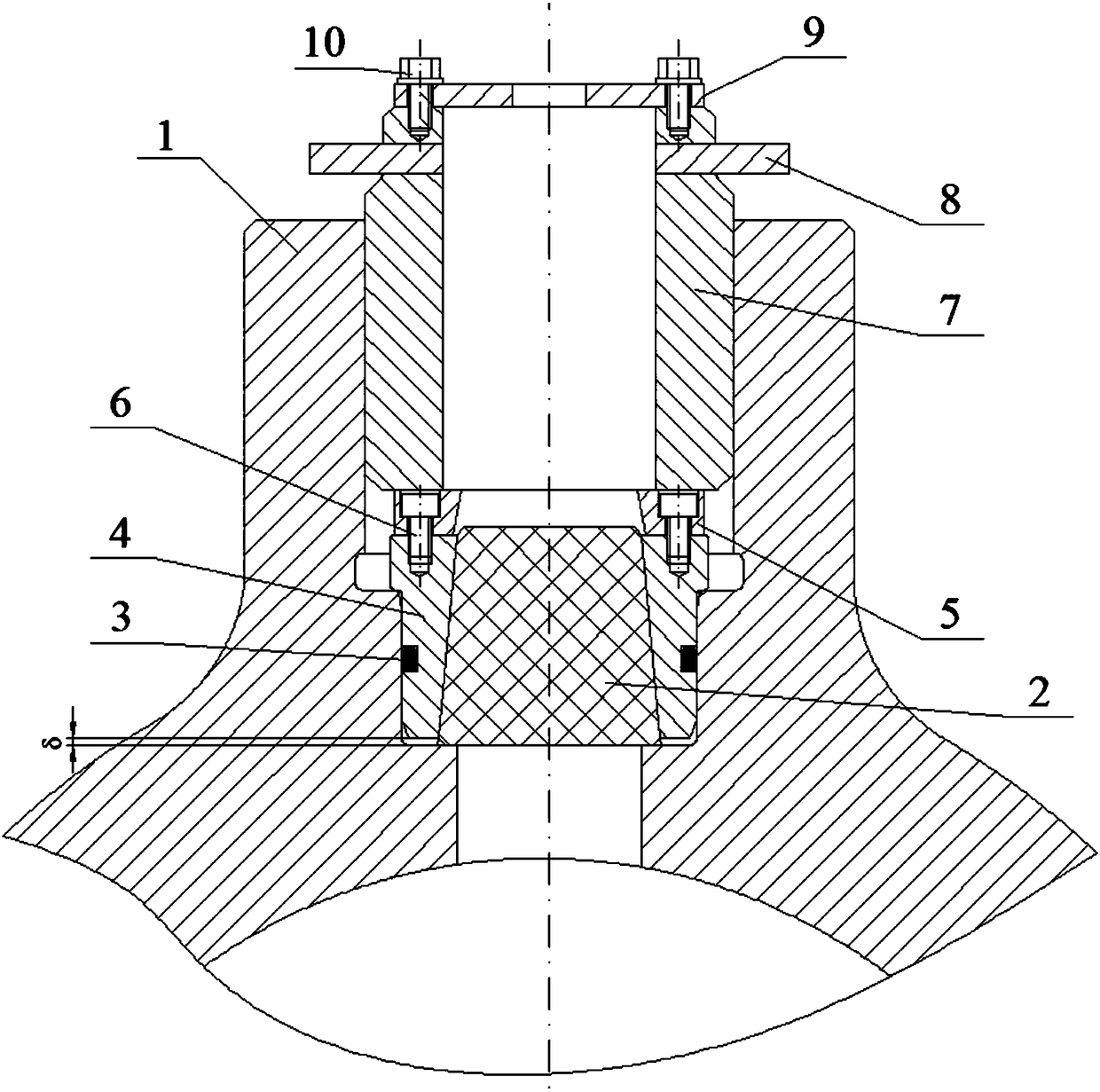

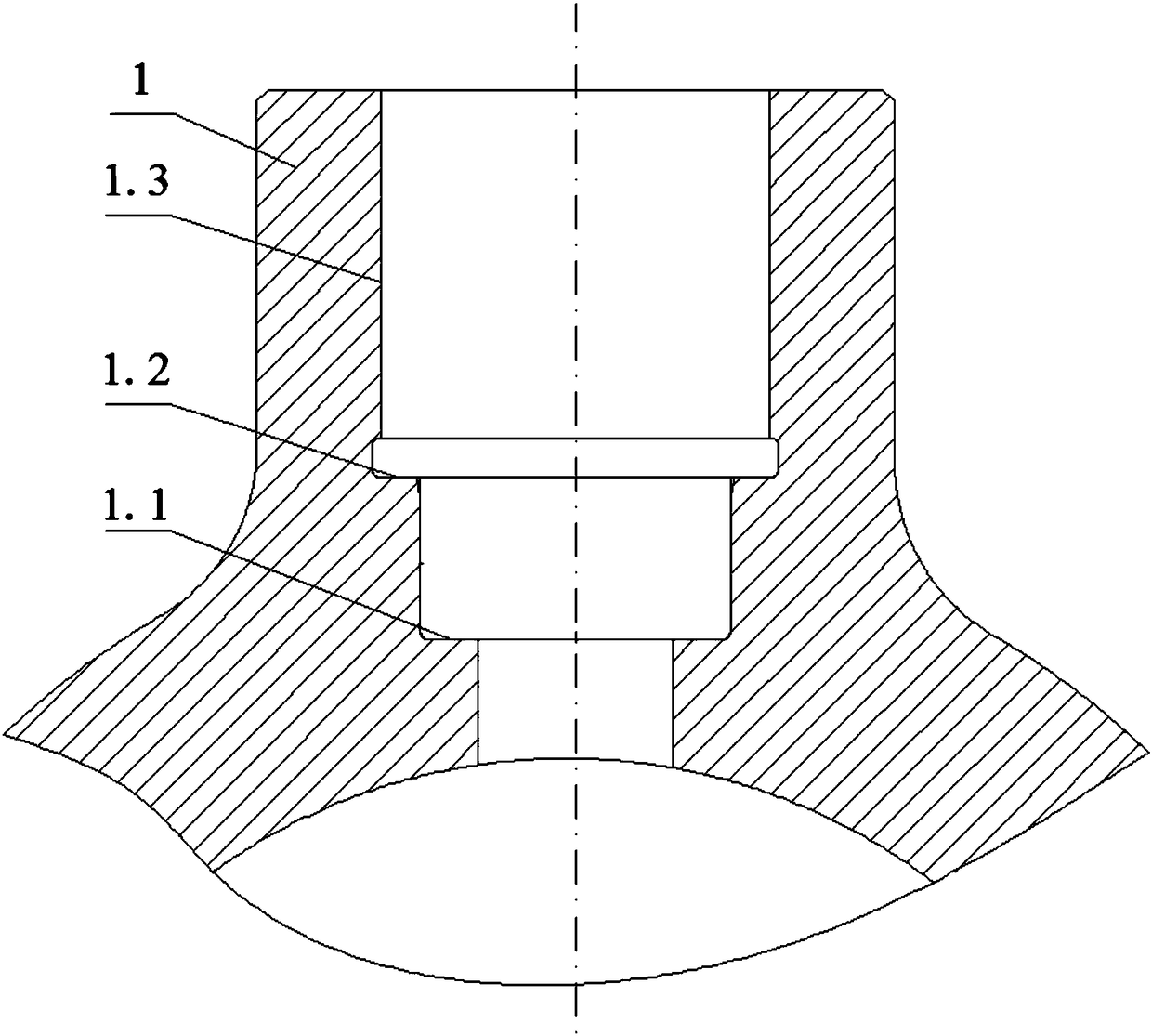

[0038] Such as Figure 2-7 The high-pressure container peeping device shown in the present invention has a design pressure of 90Mpa, a working pressure of 80Mpa, a working medium of pure water, and a peephole diameter of not less than Φ50mm. It has a peeping cylinder 1 which is integrated with the container body and communicated with the inner cavity of the container body, an annular mounting seat 4 arranged inside the peeping cylinder 1, and a light-transmitting view embedded in the annular mounting seat 4. Mirror 2.

[0039] On the inner wall of the viewing cylinder 1, alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com