Plant model extension method for petrochemical enterprises based on object-oriented analysis

A plant model, object-oriented technology, applied in the direction of total plant control, total plant control, resources, etc., can solve the problem that the core-factory model cannot meet the optimization modeling and calculation of petrochemical enterprise process or energy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

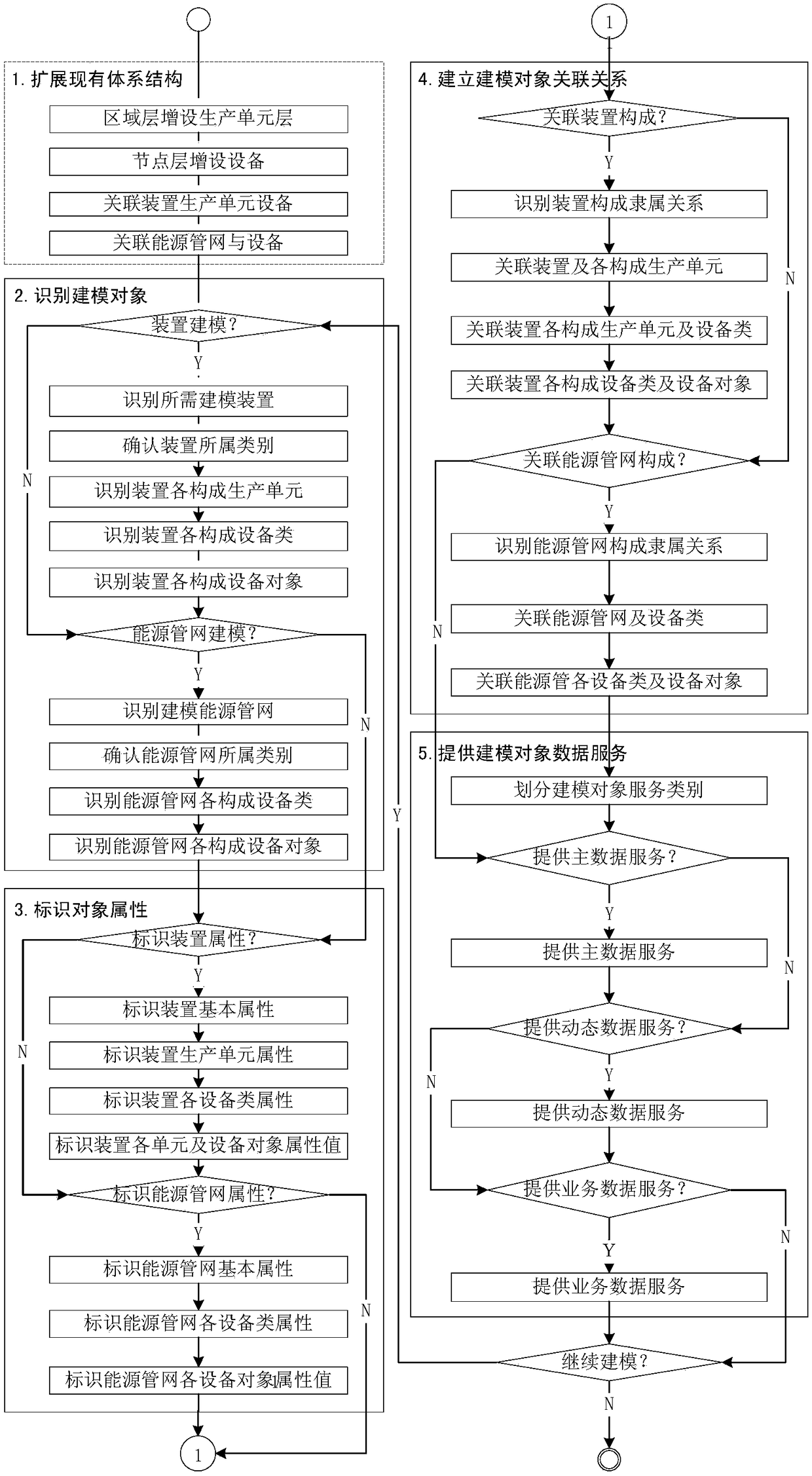

[0118] The present invention is described in detail below with reference to accompanying drawing and embodiment:

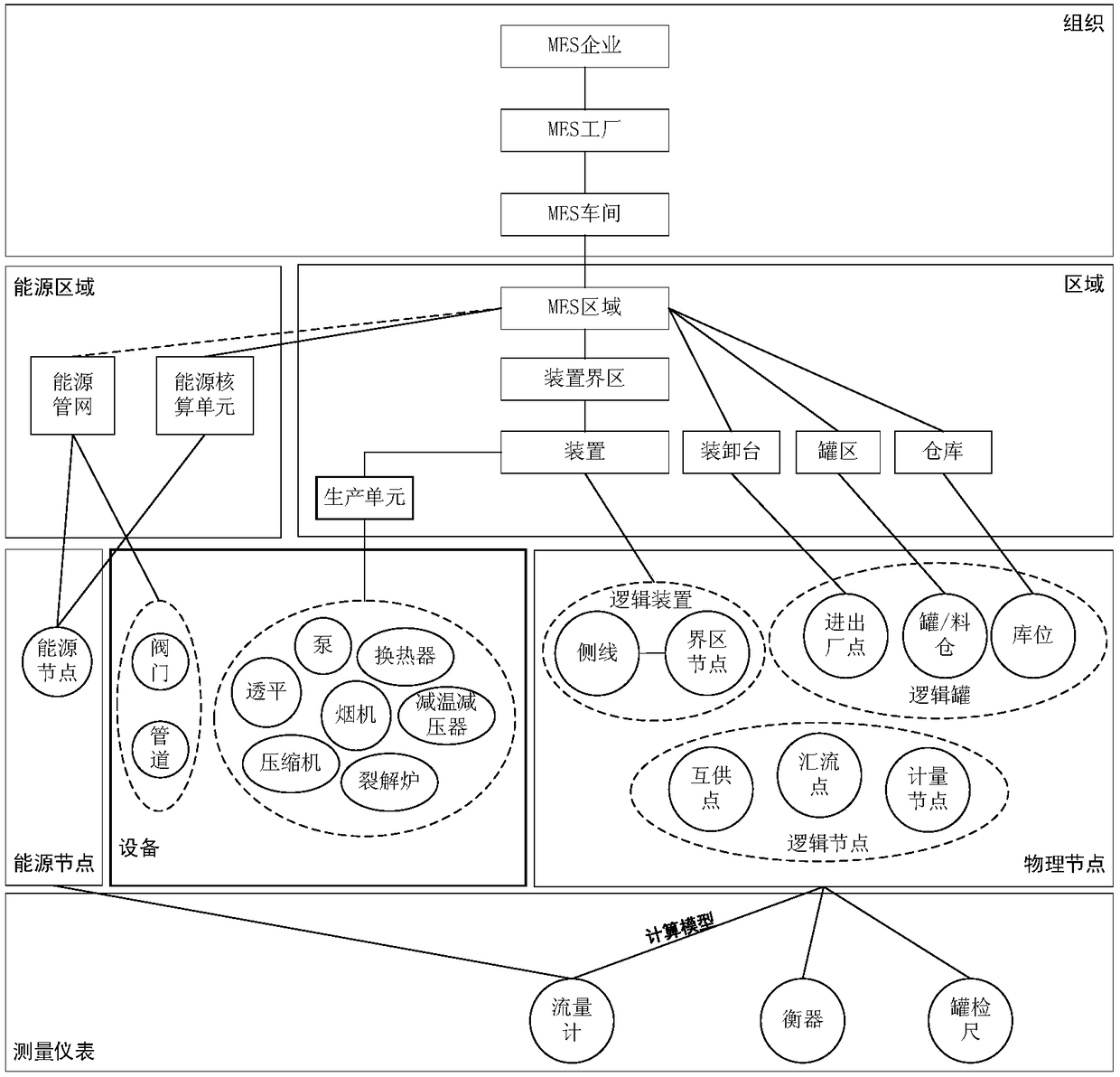

[0119]The purpose of the present invention is to overcome the deficiency that the factory model, which is the core of the existing MES products, cannot satisfy petrochemical enterprises for process or energy production process optimization modeling and calculation, and provides an object-oriented analysis-based petrochemical enterprise factory model extension method. This method is formed by using the core idea of the object-oriented analysis method—abstraction, and combining it with the process of petrochemical enterprises and the business process of energy production. Through the specific implementation steps in the method, the extension to the existing factory model can be realized.

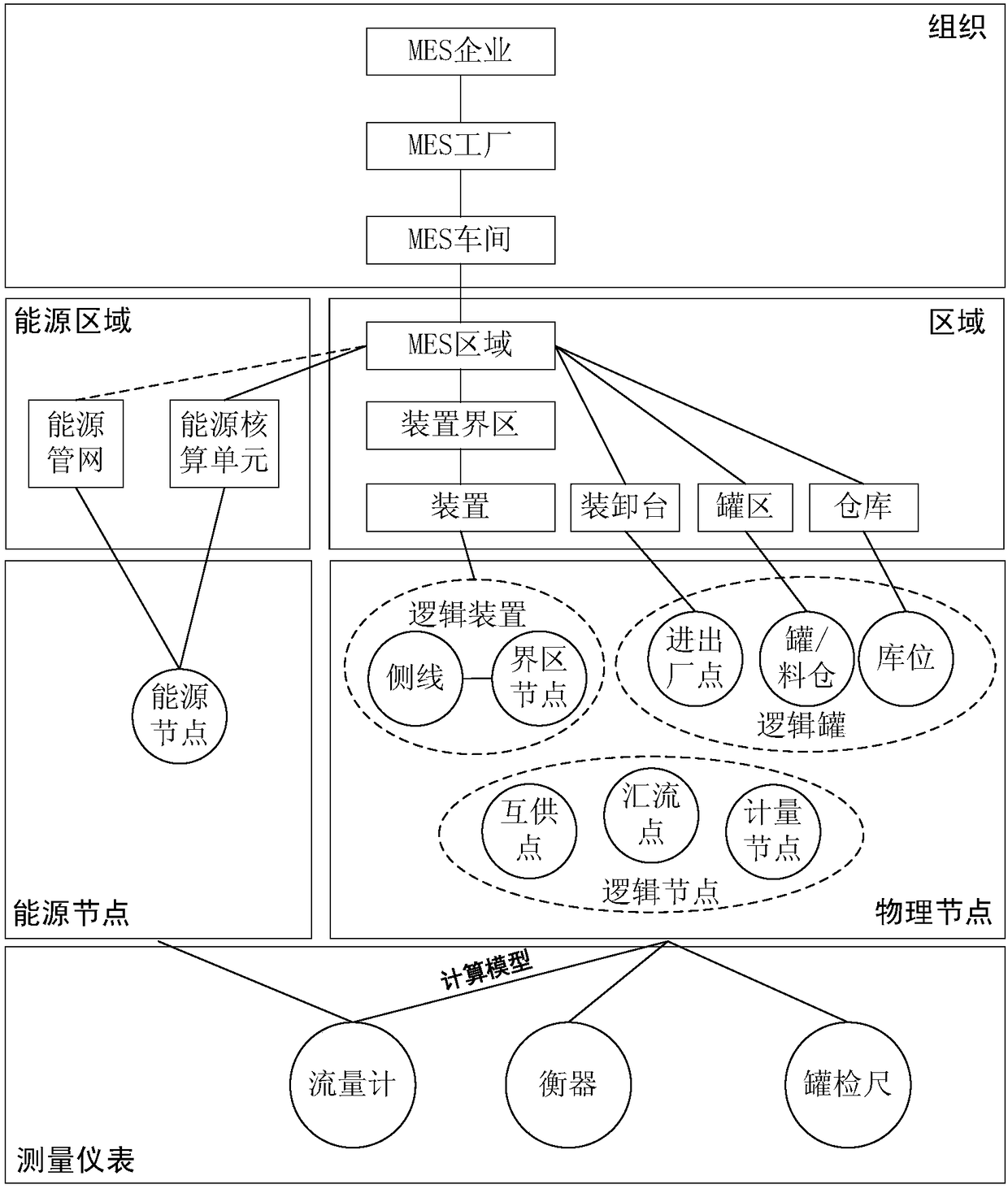

[0120] In view of the expansion is aimed at the factory model architecture adopted by the existing MES products. To this end, the architecture of the existing MES plant model i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com