Rotor device for a vacuum pump, and vacuum pump

A vacuum pump and rotor technology, which is applied to the components of the pumping device for elastic fluid, the pump device, the pump, etc., can solve the problems of time-consuming and complicated connection methods, shorten the processing time, and ensure the effect of operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

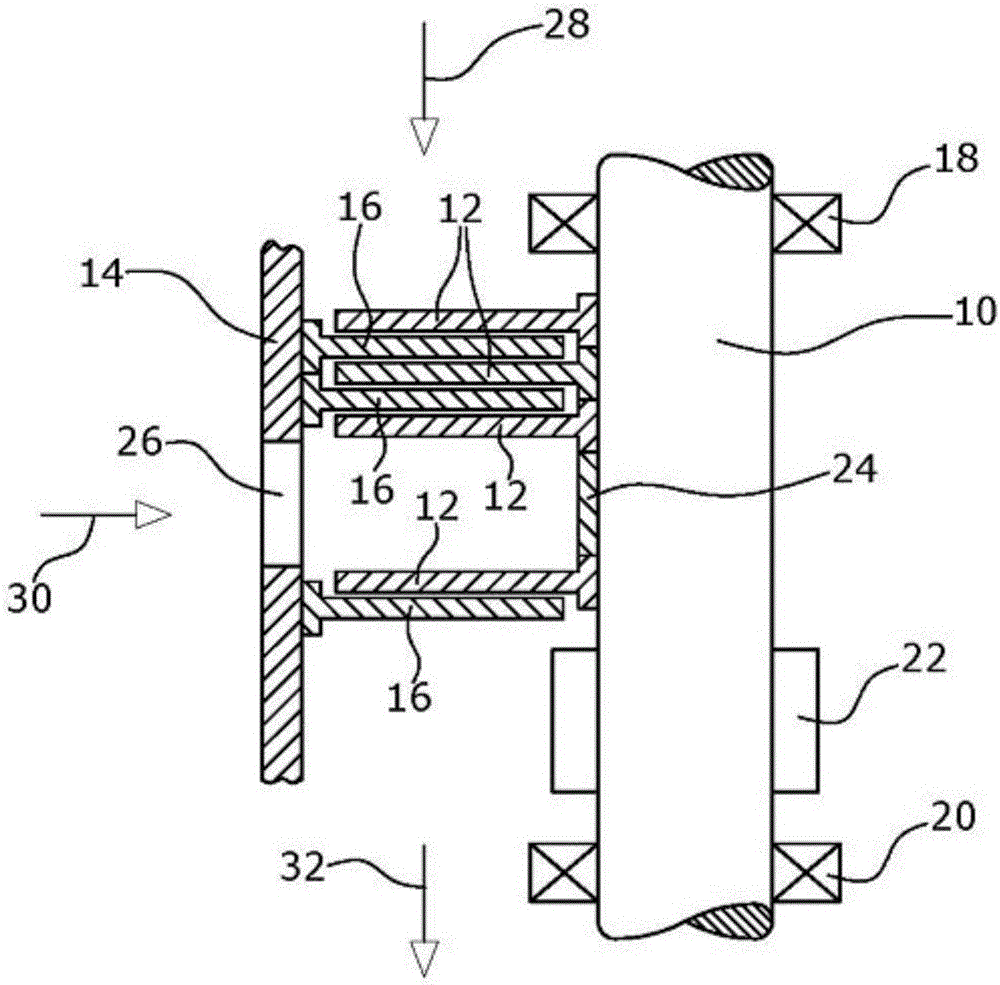

[0021] In a very simplified illustration of a turbomolecular pump, a plurality of rotor units 12 in the form of rotor disks are arranged on the shaft 10 by being pressed onto the shaft. Arranged in the pump housing 14 is a stator unit 16 , which may be a stator disk 16 in the embodiment shown.

[0022] The rotary shaft 10 is further supported in the pump housing 14 via bearing units 18 , 20 and driven by a drive 22 .

[0023] In the illustrated embodiment, a sleeve-like spacer unit 24 is further provided between the two rotor disks 12 . The intermediate inlet 26 is thus formed.

[0024] Thus, the vacuum pump shown schematically in the drawing draws the medium in the direction of arrow 28 to pass through the main inlet. Further, the medium is sucked in the direction of arrow 30 via the intermediate inlet 26 . The two media sucked in are delivered towards the outlet indicated by arrow 32 .

[0025] According to the invention, the shaft 10 is made of stainless steel in a pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com