Automatic dried soybean milk film roll machine

A bean gluten machine and automatic technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of low production efficiency, loss of nutrition, difficult to clean, etc., to achieve the effect of improving production efficiency, ensuring nutrition, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

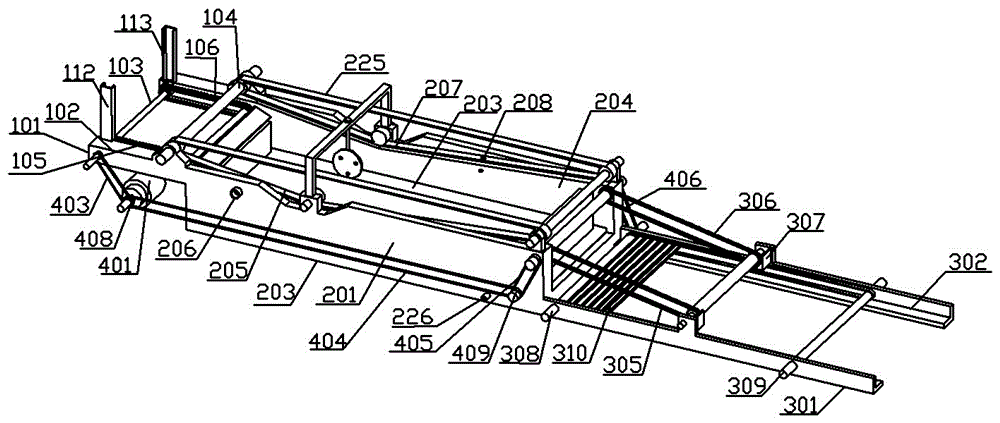

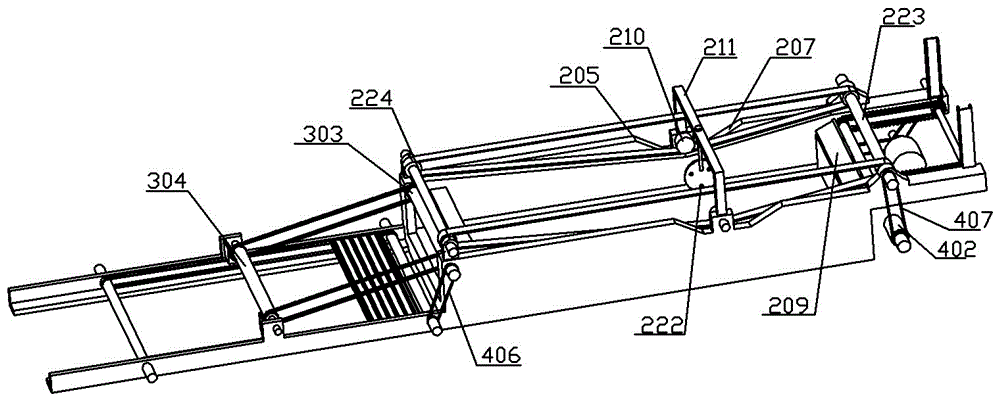

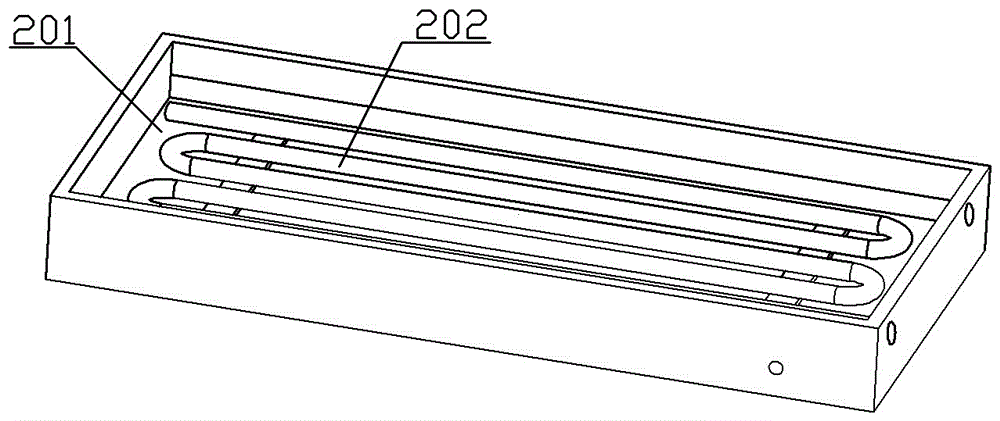

[0026] See attached figure 1 , figure 2 , image 3 , Figure 4 As shown, the automatic bean gluten machine in this embodiment includes a frame on which a soymilk heating bed, a bean gluten roller transport platform, an air supply system and a power transmission system are installed. That is, from the input direction to the output direction) are divided into bean gluten roller feeding mechanism 101 and soybean milk heating tank 201 in turn. The soybean gluten roller output end of the soybean milk heating tank 201.

[0027]The bean gluten roller feeding mechanism 101 includes a mounting table 102, which is welded or bolted to the tank wall of the soybean milk heating tank 201. The mounting table 102 is divided into a left mounting part, a right mounting part, and between the left and right mounting parts. Along the conveying direction of the bean gluten roller, the driving shaft 103 of the feeding roller chain and the driven shaft 104 of the feeding roller chain are success...

Embodiment 2

[0041] See attached figure 1 , figure 2 , image 3 , Figure 5 As shown, the difference between the present embodiment 2 and the embodiment 1 is: the roller chain (collectively referred to as the left roller chain 305 and the right roller chain 306), the roller chain (the left roller chain 105, the right roller chain 106) have the same structure, the chain plate unit includes an outer chain plate group and an inner chain plate group from left to right, each outer chain plate group contains two parallel outer chain plates 107, and each inner chain plate group includes Two parallel inner chain plates 108 . The left end of the inner chain plate group is positioned between the two outer chain plates 107 of the outer chain plate group on its left side, and the inner chain plate 108 and the outer chain plate 107 are connected by a rotating pin, and the ends of the rotating pin are riveted to prevent internal The chain plate 108 and the outer chain plate 107 slide back. The rig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap