Helical-band-type multifunctional reaction device

A reaction device and multi-functional technology, which is applied in the field of ribbon-type multi-functional reaction devices, can solve problems such as costing a lot of money, and achieve the effects of cost savings, strong practical value, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

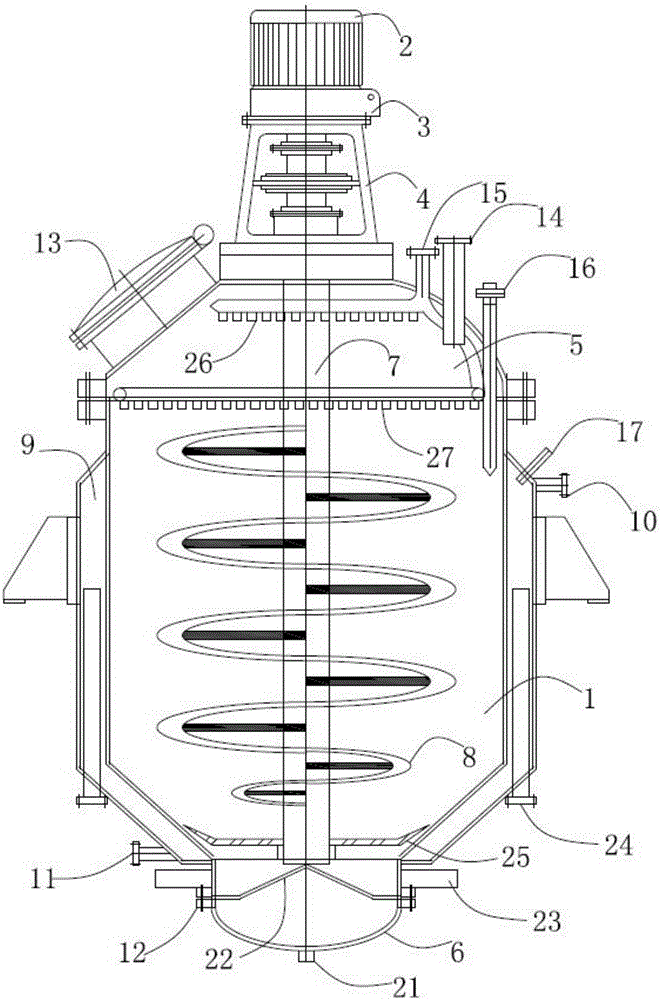

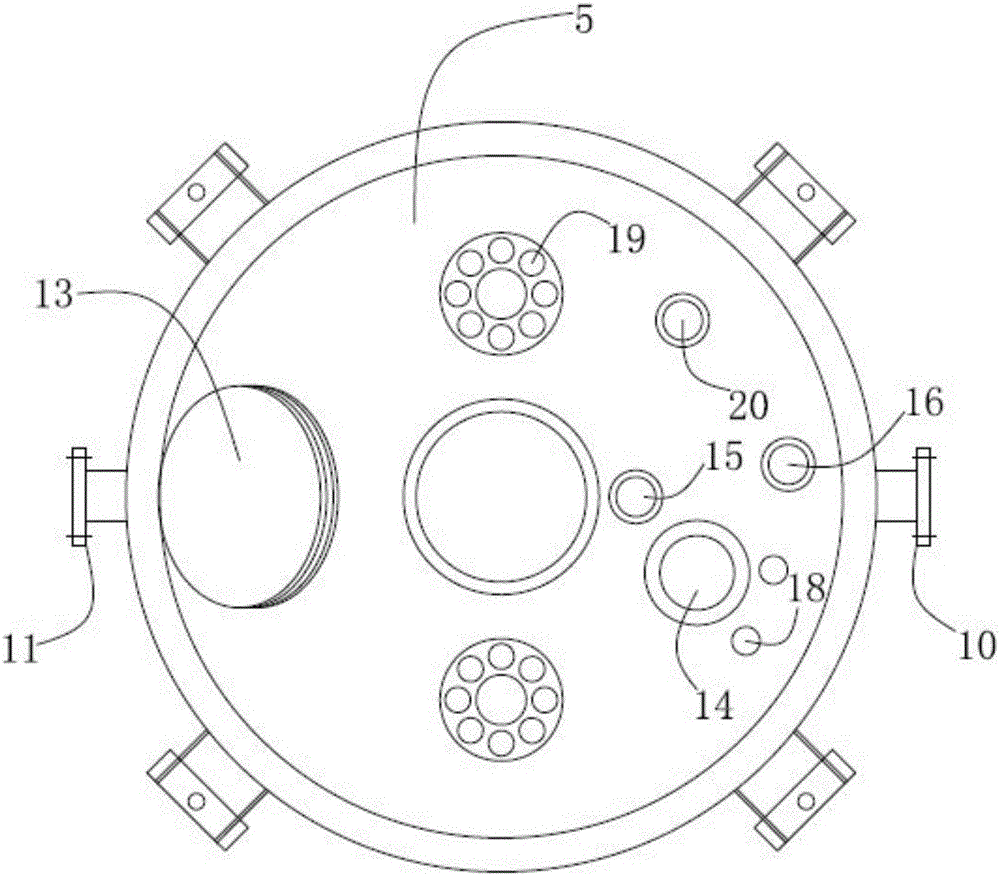

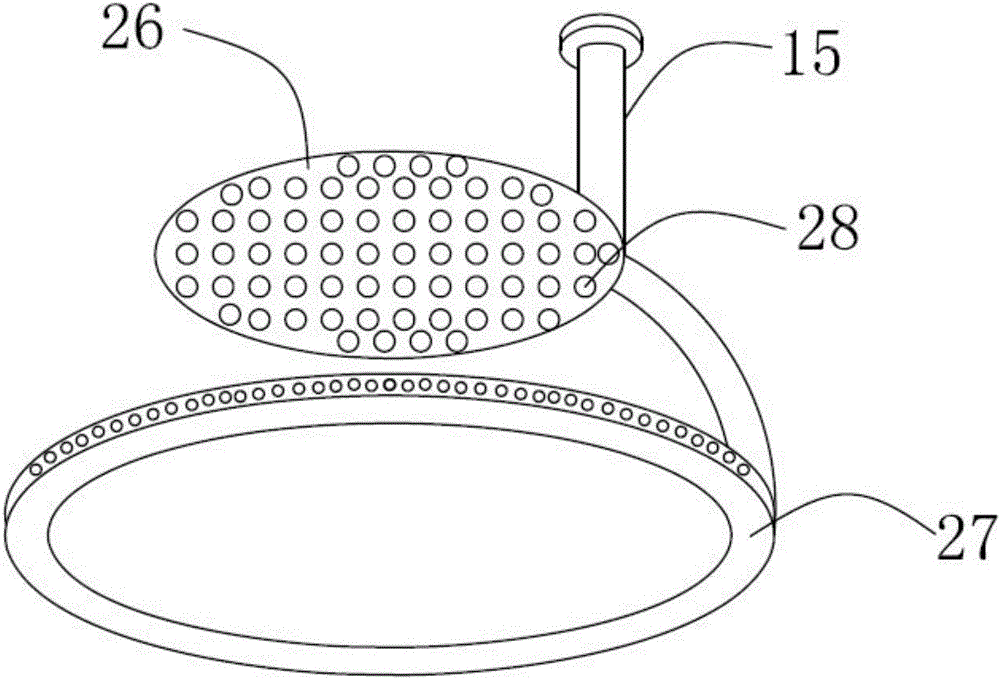

[0019] Through the following examples, combined with the attached Figure 1-3 , the technical solution of the present invention will be further specifically described.

[0020] Ribbon-type multifunctional reaction device, including a kettle body 1 and a kettle cover 5, a bottom valve 6 is provided under the kettle body 1, and the kettle body 1, kettle cover 5, and bottom valve 6 are connected by flanges 12 and bolts Fixed, the kettle cover 5 is provided with a rotating shaft 7 extending into the kettle body 1, the rotating shaft 7 is provided with a ribbon type stirring paddle 8, the bottom end of the rotating shaft 7 is provided with a scraper 25, and the kettle cover 5 is provided with a spray port 15, and the spray port 15 is connected to a solid disc nozzle 26 and a circular tube nozzle 27 in the kettle. The injection port 28 of the circular pipe nozzle 27 is annularly arranged on the connecting flange 12 of the kettle body 1 and the kettle cover 5, and the pipe body of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com