Wet-process precise grading device

A grading device and precise technology, applied in the direction of swirl device, the device in which the axial direction of the swirl can be reversed, etc., can solve the problems of inability to meet the requirements of grading, poor uniformity, and poor spherical resin grading effect. Guarantee the accuracy and solve the effect of the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

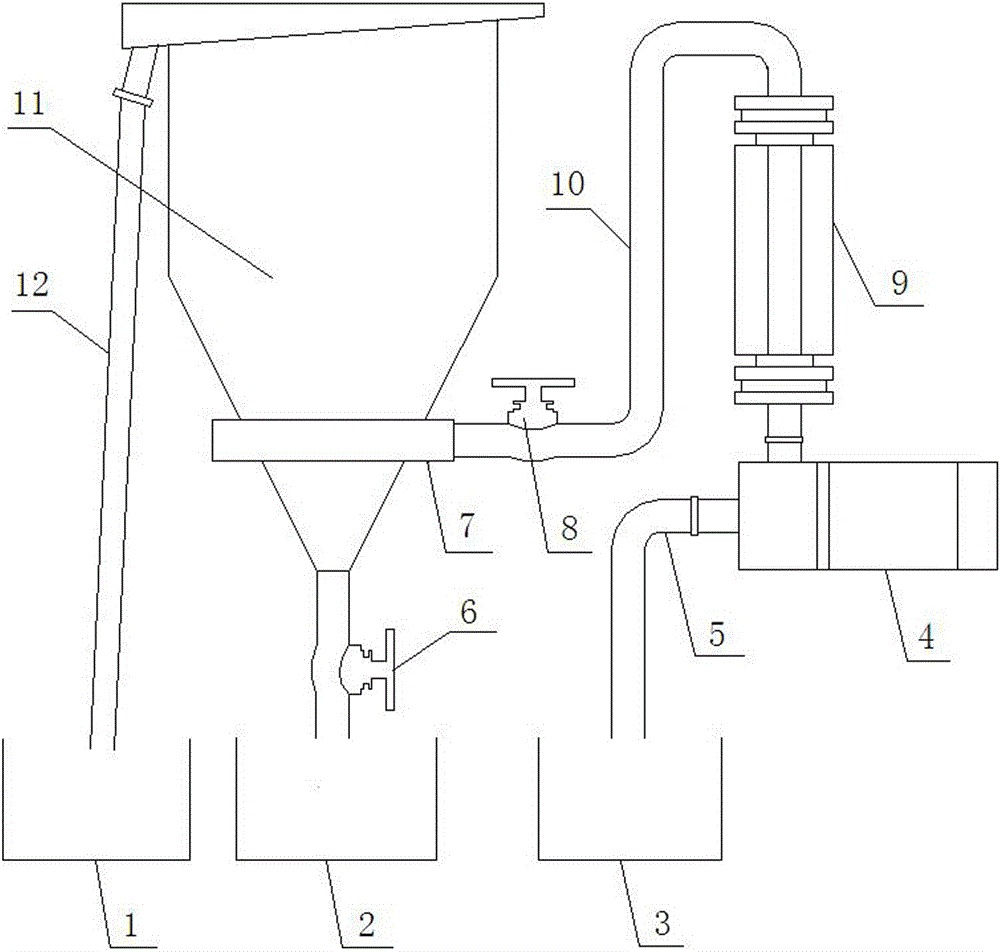

[0010] The structure of the wet precision grading device of the present invention will be described in detail below in conjunction with the accompanying drawings.

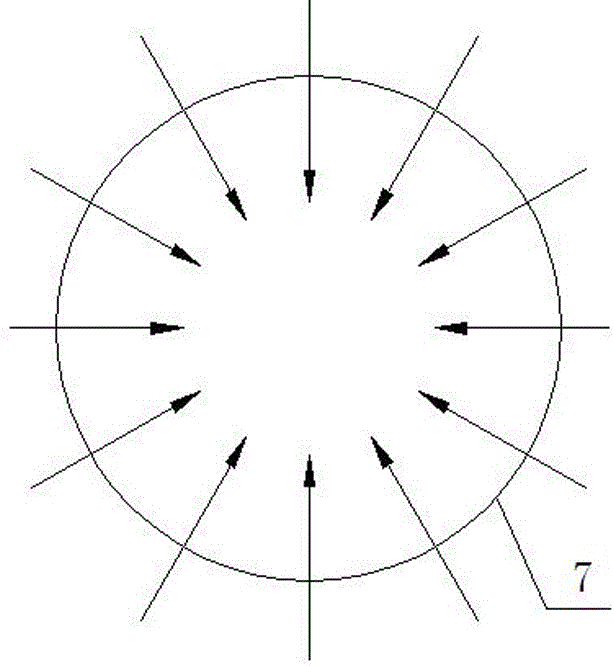

[0011] see figure 1 , the wet precision classification device of the present invention comprises an overflow cylinder 11, a flow equalizer 7, a flow meter 9 and a water pump 4, and the water pump 4 passes through the flow meter 9, the pipeline 10, the stop valve 8 on the pipeline 10, the flow equalizer 7 and the overflow Flow cylinder 11 realizes connection, and the inlet of water pump 4 is connected to the slurry tank 3 to be classified through pipeline 5, and water pump 4 is a miniature magnetic force pump, and overflow cylinder 11 is made by stainless steel. Wherein, the upper part of the overflow tube 11 is cylindrical, and the lower part is conical. The present invention designs the diameter of the overflow tube 11 according to the settling velocity of the spherical polymer particles, and the selection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com