Automatic compensation type supporting wheel device and bridge type machining device comprising automatic compensation type supporting wheel device

An automatic compensation and roller technology, applied in metal processing machinery parts, metal processing equipment, stone processing equipment, etc., can solve the problems of increasing material cost and driving cost, increasing the weight of the machine head, losing the stability function, etc., and achieving a compact structure. , The effect of convenient adjustment and maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

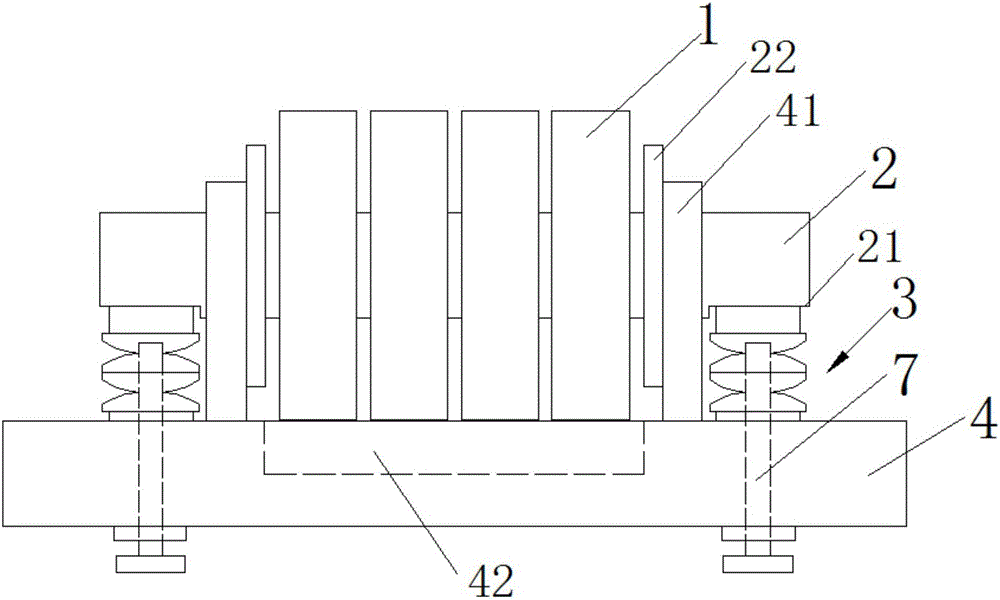

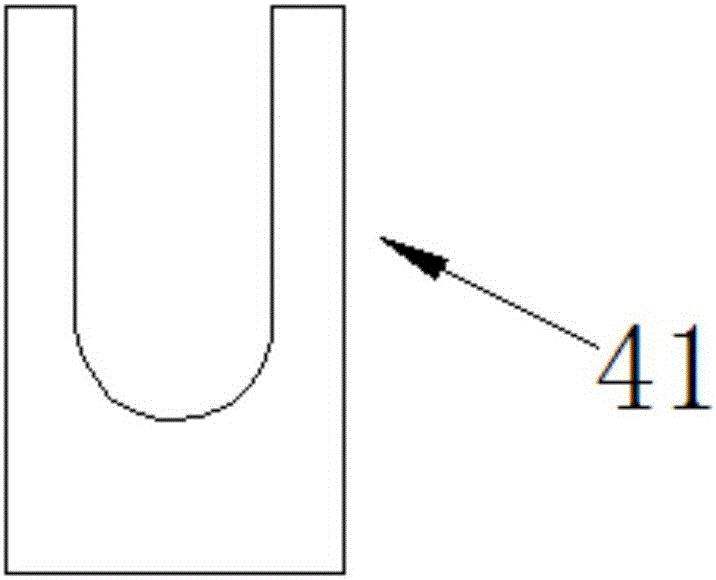

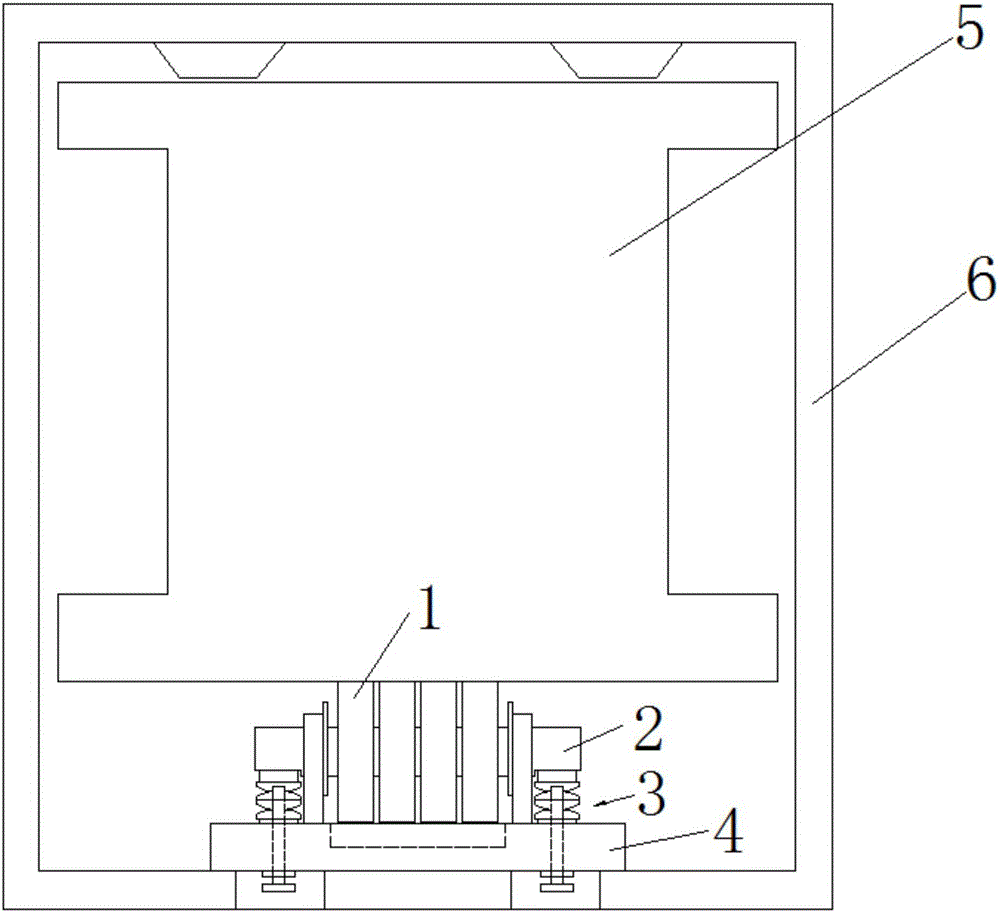

[0025] like figure 1 As shown, an automatic compensating roller device includes a bearing 1 for supporting heavy objects, a bearing support rod 2, an elastic mechanism 3 symmetrically arranged at both ends of the bearing 1, a support 4 and bolts 7; the bearing 1 is set In the middle part of the bearing support rod 2; the bearing support rod 2 is elastically loaded by the bearing support 4 through the elastic mechanism 3; the bolt 7 is threadedly connected with the support support 4 and one end penetrates the elastic mechanism 3; The bearing support rod 2 is horizontally shifted by the limiting lug 41; the bearing 4 is also provided with a bearing relief groove 42 in cooperation with the bearing 1.

[0026] Wherein, a baffle 22 is symmetrically and fixedly arranged on both sides of the bearing 1 on the bearing support rod 2 ;

[0027] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com