Forced return structure of the mold

A mold and return pin technology, which is applied in the field of forced return structure of the mold, can solve the problems of light load spring oblique pin return difficulty, large pin size, large withdrawal stroke and angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

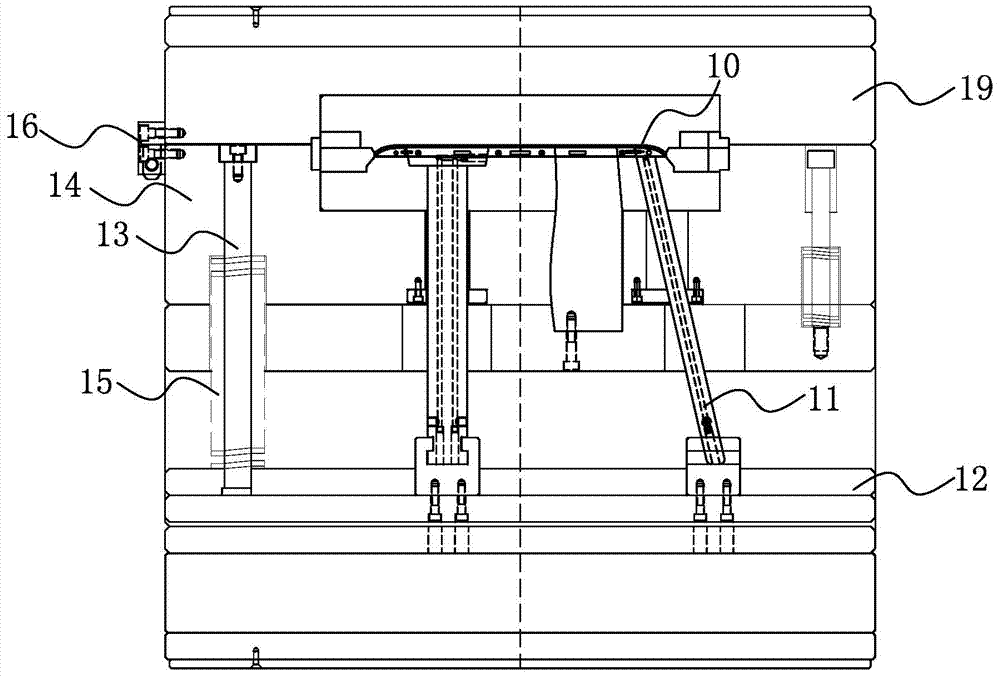

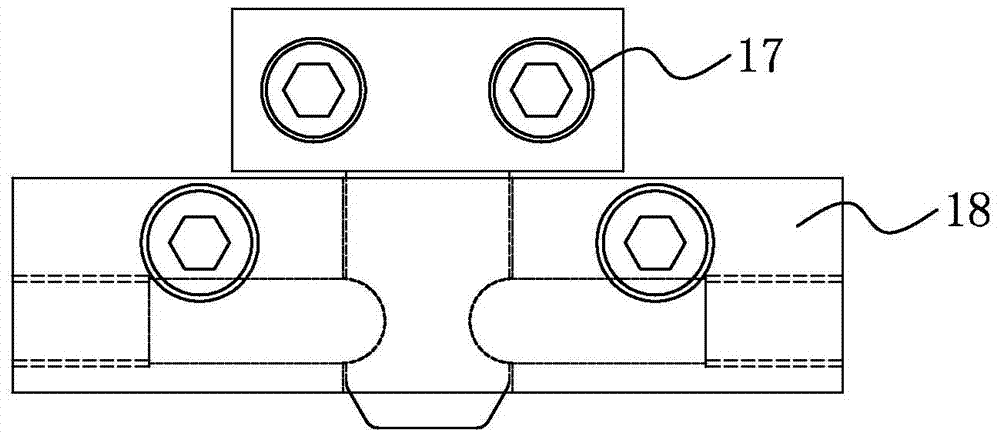

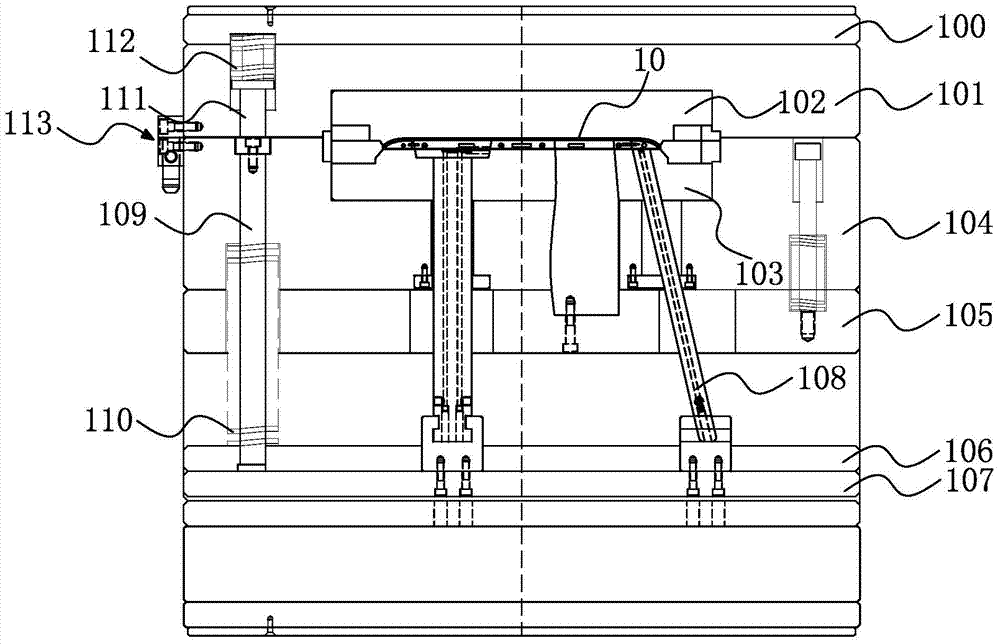

[0028] see image 3 and Figure 4 shown, where image 3 A schematic diagram illustrating the forced return structure of the mold of the present invention, Figure 4 A schematic diagram of the shutter in the forced return structure of the mold of the present invention is shown.

[0029] In this embodiment, the forced return structure of the mold of the present invention is used to pour the hot runner into the molded product, and the mold sequentially includes a lower fixing plate 100, a male template 101, a male mold core 102, a female mold core 103, Mother template 104, slider peeling plate 105, upper ejector plate 106 and lower ejector plate 107, the forced return structure of the mold includes:

[0030] Slanted pin 108, one end of which is located in the upper ejection plate 106, and the other end forms the product 10;

[0031] The first return pin 109, one end is fixed in the said mother template 104, and the other end is fixed in the said upper ejection plate 106;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com