Anti-falling wheelbarrow with labor-saving unloading

A wheelbarrow, anti-falling technology, applied to the direction of trolleys, single-axis trolleys, trolley accessories, etc., can solve the problems of cart rollover, cart tipping, and impact on unloading, so as to reduce the height difference change, The effect of small center of gravity change and stable unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

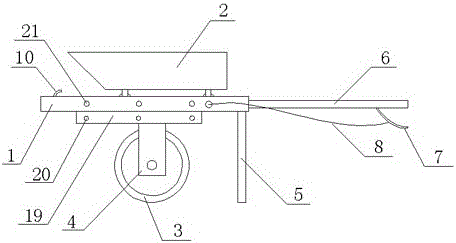

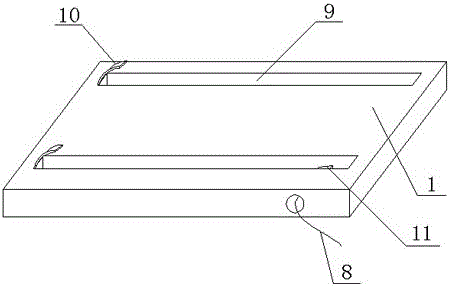

[0041] Such as Figure 1~Figure 7 As shown, the unloading and labor-saving anti-inverted wheelbarrow described in this embodiment includes a car plate 1, a body 2, a wheel 3, a support rod 5, and a handle 6, and the body 2 is located on the car plate 1. Above the wheel, the wheel 3 is fixed under the car plate 1 through the wheel plate 4, the support rod 5 and the handle 6 are fixed to the same end of the car plate 1, and also includes a mechanism for realizing the back and forth movement of the body 2 on the car plate 1. A sliding device, a locking device for fixing the vehicle body 2 and an anti-falling device arranged on both sides of the vehicle panel 1 can realize downward opening and stowing toward the bottom of the vehicle panel 1.

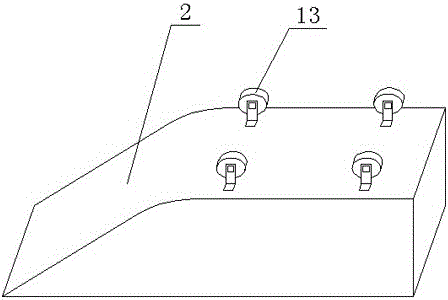

[0042] The sliding device of this embodiment includes a guide chute 9 provided on the vehicle panel 1 and a guide wheel 13 provided at the bottom of the vehicle body 2, and the guide wheel 13 is matched with the guide chute 9.

[0043] The lock...

Embodiment 2

[0053] Such as Picture 9 As shown, on the basis of embodiment 1, this embodiment further includes an auxiliary plate 16 and a plurality of second springs 17. The auxiliary plate 16 is hinged to the end of the vehicle plate 1 away from the handlebar 6, and one end of the second spring 17 is fixed to the auxiliary Below the board 16, the other end is fixed on the vehicle board 1.

[0054] This embodiment also includes a number of third springs 18. One end of the third spring 18 is fixed on the bottom of the vehicle body 2 and the other end is fixed on the auxiliary plate 16.

[0055] This embodiment adopts the above structure to solve the following problems:

[0056] 1. Solve the problem that the cart may tip over when the cart is unloading. Traditional carts generally adopt the method of direct dumping, raising the handlebars, turning the body forward to complete the unloading. In this process, the heavy raw materials or construction waste, plus the weight of the frame itself, lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com