Garbage can lifting and dumping mechanism

A technology for waste bins and garbage trucks, applied in emptying containers, loading/unloading, bottle filling, etc., can solve the problems of tailgate pollution, pollution of the rear of the vehicle, increase maintenance costs, etc., to extend service life and good versatility , the effect of offsetting machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

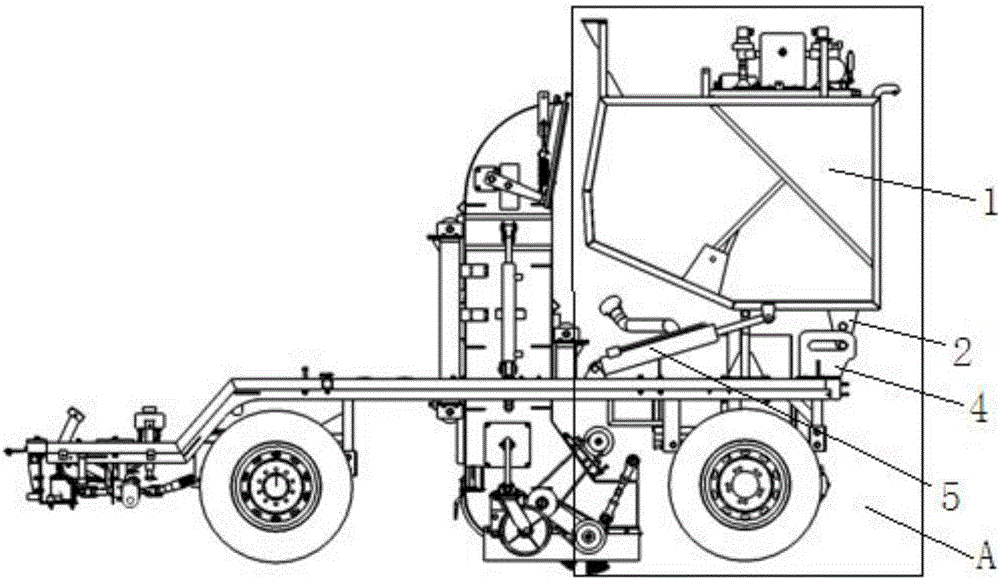

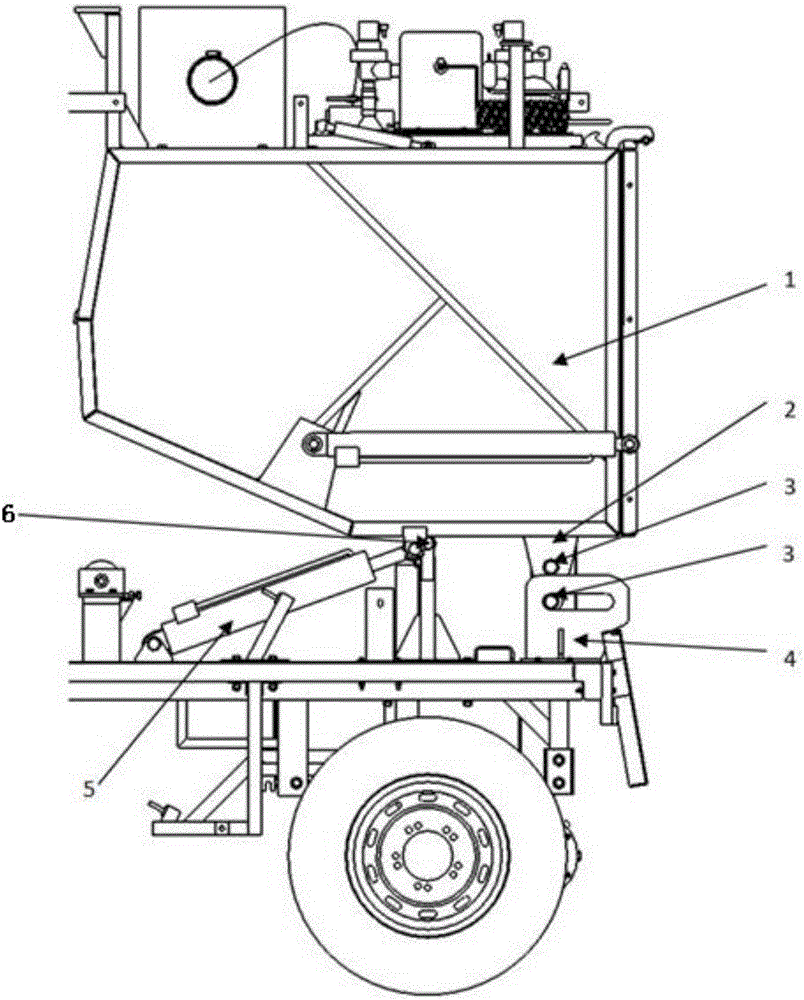

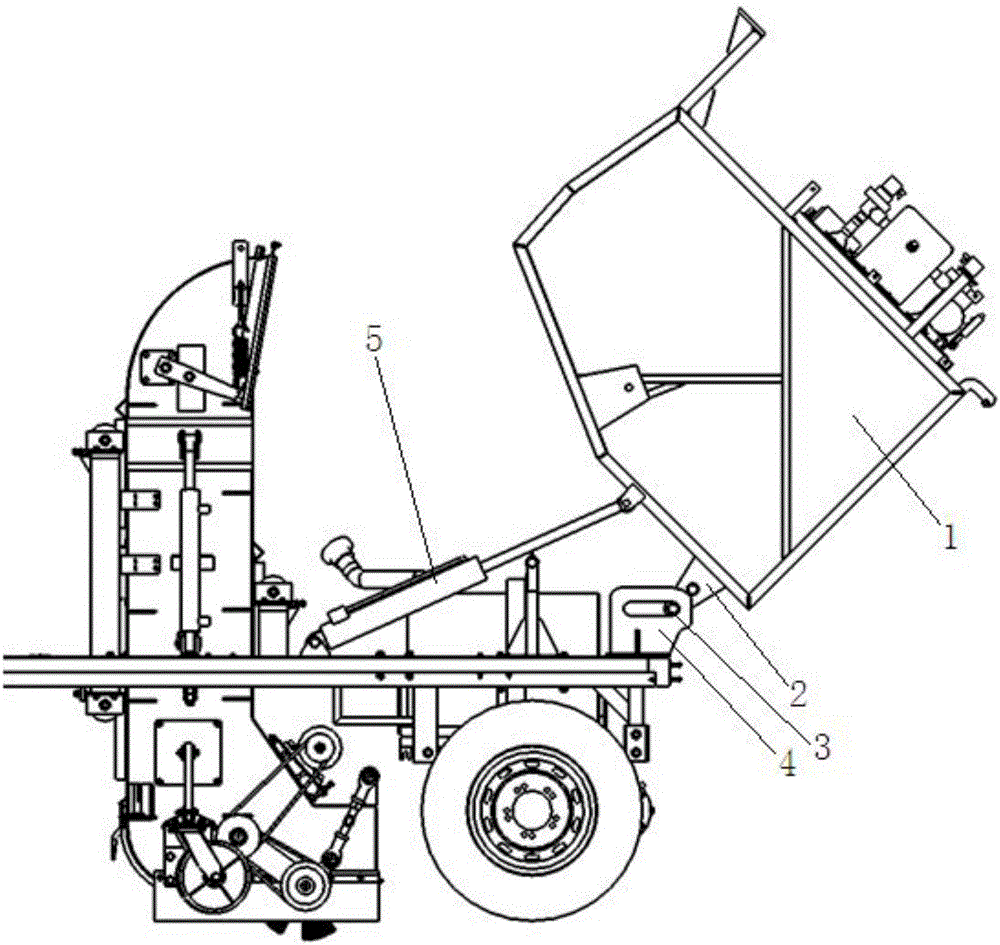

[0019] like Figure 1~Figure 3 As shown, a garbage bin lifting and dumping mechanism includes a garbage bin 1, a box body seat 2, a first nylon sleeve 3, a rotating shaft seat 4 and a lifting cylinder 5.

[0020] The dustbin 1 and the box body seat 2 are connected into one body, the rotating shaft seat 4 is connected with the dustbin 1 through the first nylon sleeve 3, and the lower part of the dustbin 1 is provided with a second nylon sleeve 6 for support, and the lifting cylinder 5 Connect the dustbin 1 and the car body. When the garbage bin 1 is lifted and dumped under the action of the lifting cylinder 5, the garbage bin 1 will slide backward for a specified distance. This distance is determined by the length of the long hole of the shaft seat 4. During this process, the first nylon sleeve 3 Rotate all the time, there is a rotating shaft up and down respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com