Compound machine

A compound machine and compound device technology, applied in the field of compound machines, can solve the problems of reduced service life and reliability of the winding mechanism, formation of stress concentration, large acting force, etc., to prevent displacement jumping, high reliability, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

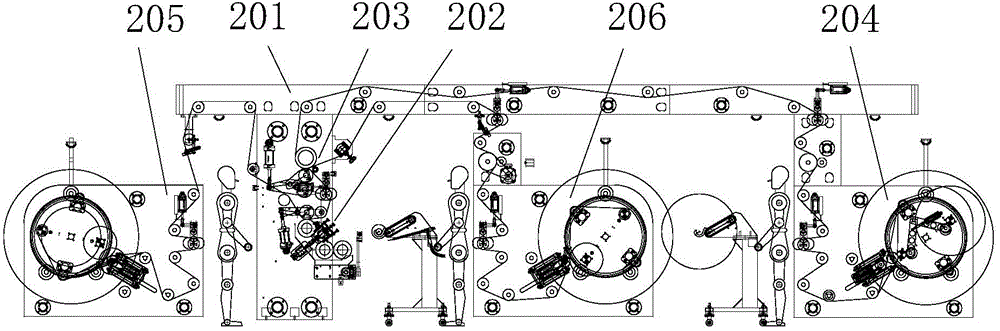

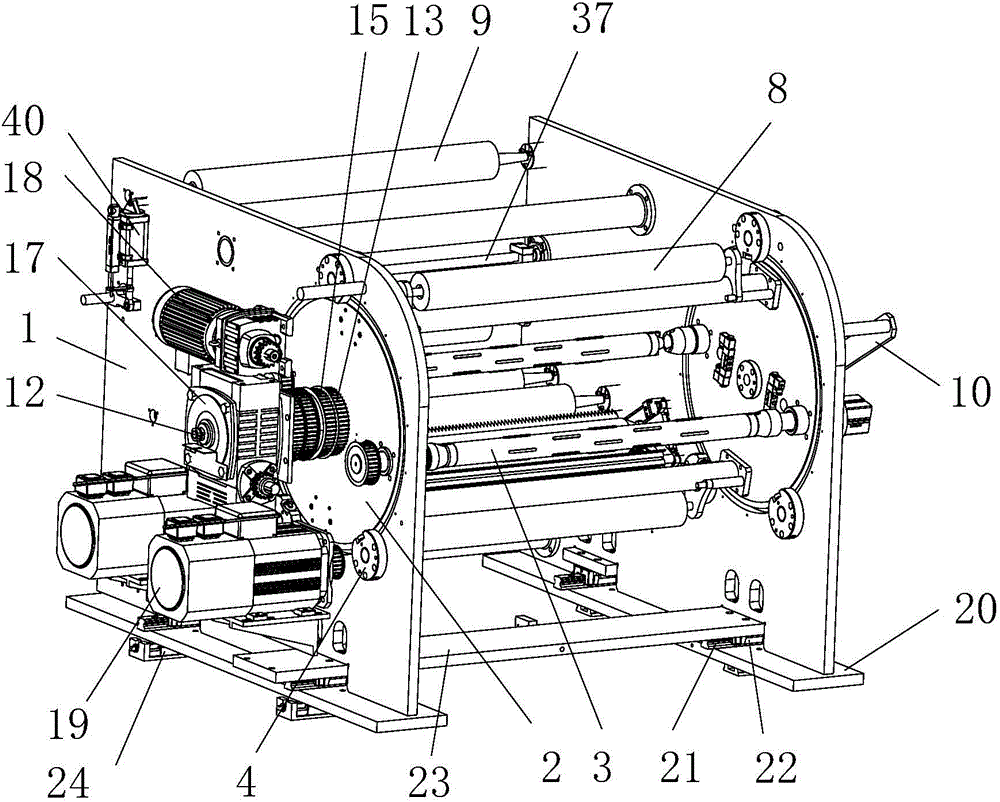

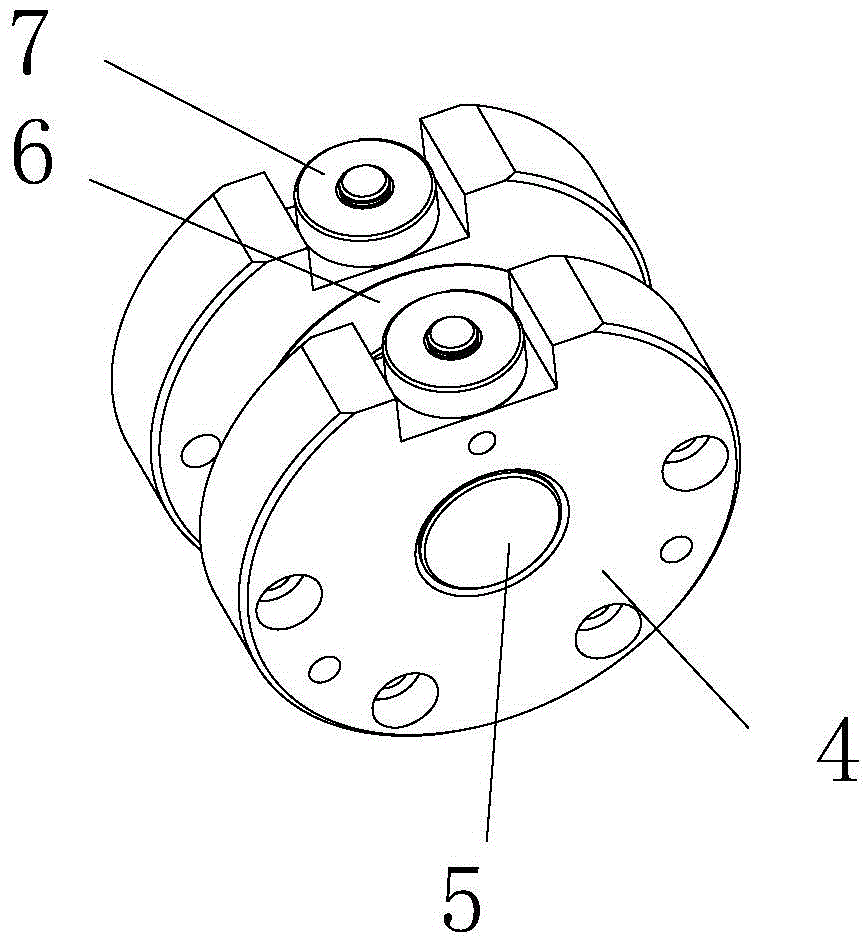

[0045] Such as figure 1 Shown is a schematic structural diagram of a compound machine embodiment of the present invention. The composite machine of this embodiment includes a top guide roller assembly 201, a coating device 202, a composite device 203, a winding mechanism 204, a first unwinding mechanism 205 corresponding to the coating device 202, and a first unwinding mechanism 205 corresponding to the composite device 203. The second unwinding mechanism 206, the winding mechanism 204, the first unwinding mechanism 205 and the second unwinding mechanism 206 all adopt the disc type winding and unwinding mechanism with the same structure. The coating device 202 and the composite d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com