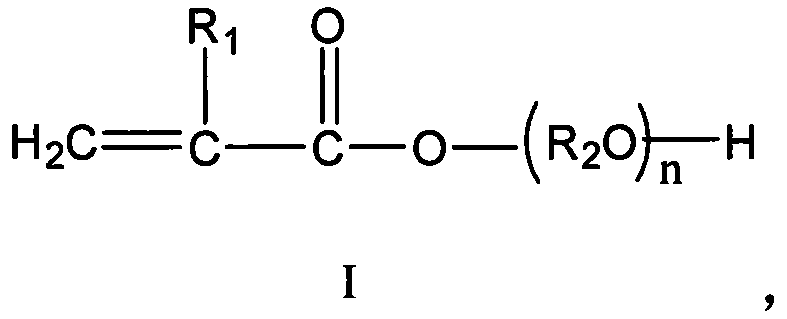

Radical polymerizable polyurethane composition

A technology of polyurethane and composition, which is applied in the field of polyurethane composition, and can solve problems such as cracking, high temperature of cured resin, and damage to mechanical and physical properties of cured resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0077] Embodiment 1-5: the preparation of polyurethane composition

Embodiment 1

[0078] Example 1: Mix HPA (100 parts) and styrene (100 parts) at room temperature, add 0.1 part of T-12, and gradually add isocyanate A (100 parts) to the above solution under stirring. , continue to stir and react for 5 hours to completely react all NCO groups to obtain a polyurethane composition.

Embodiment 2

[0079] Example 2: Mix HPA (100 parts) and styrene (100 parts) at room temperature, add 0.1 part of T-12, and gradually add isocyanate B (100 parts) to the above solution under stirring, after the dropwise addition , continue to stir and react for 5 hours to completely react all NCO groups to obtain a polyurethane composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com