Vibration type thick material sealing and sewing device

A vibration and sewing technology, applied in the field of clothing sewing, can solve problems such as easy water seepage, material puncture, and affecting the use effect of clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

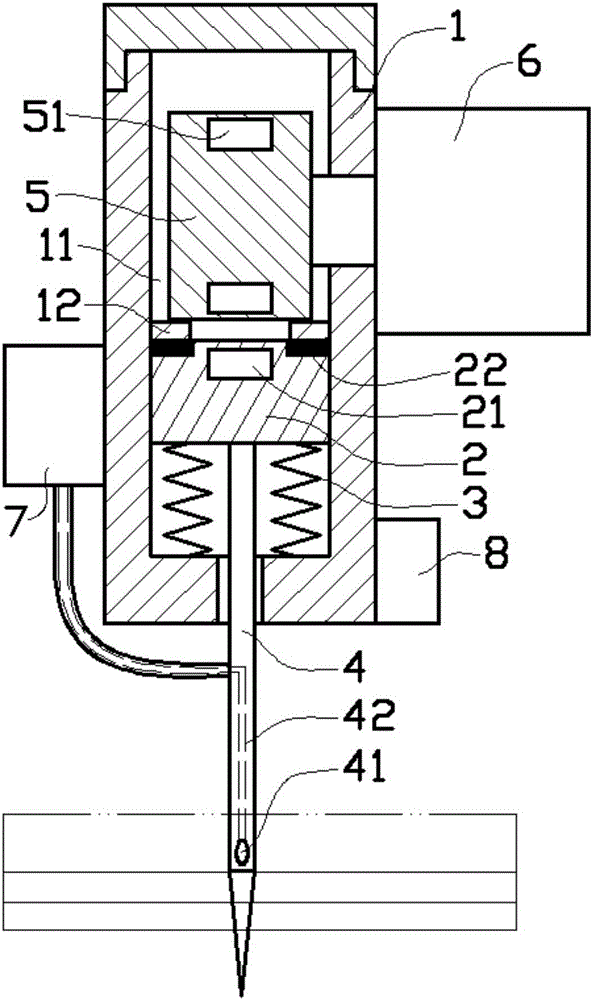

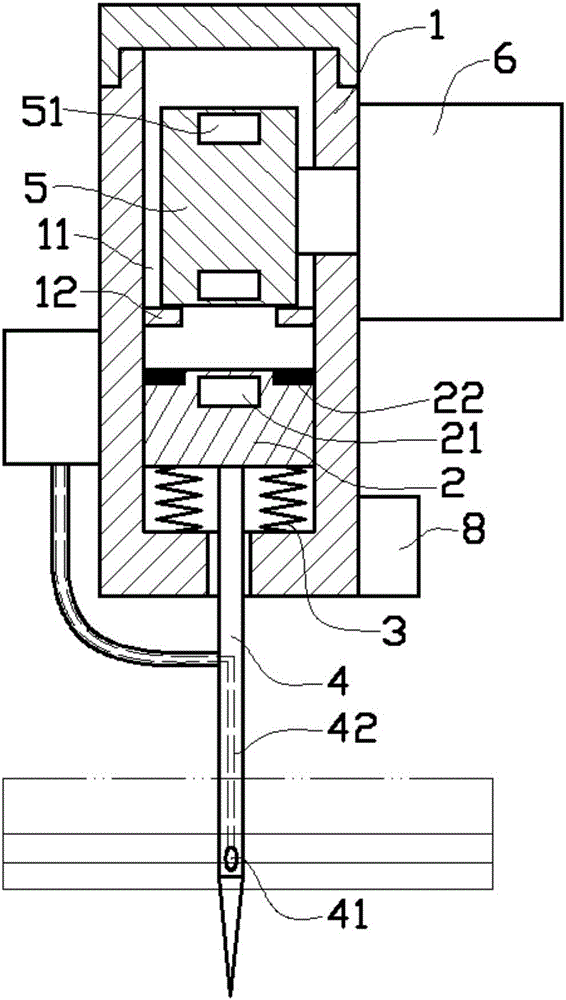

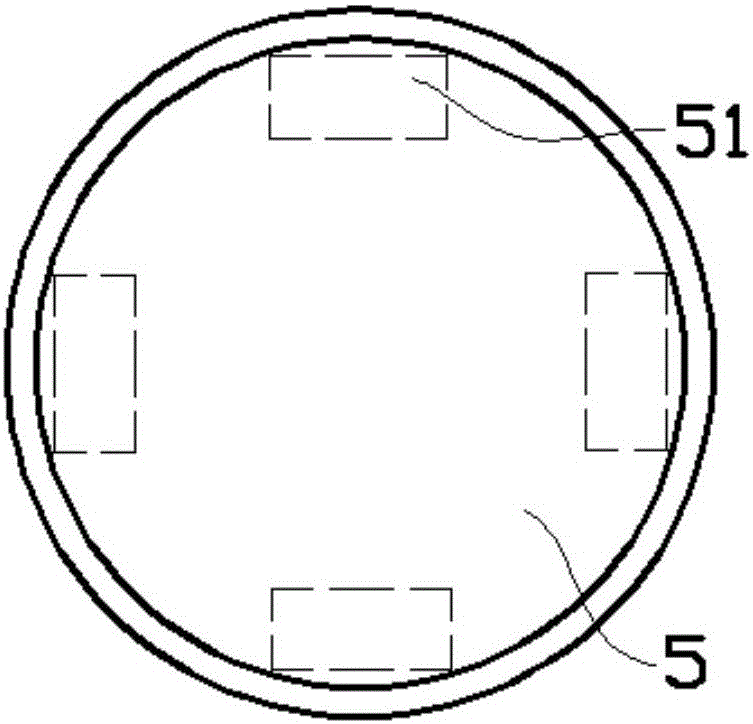

[0015] Such as figure 1 with figure 2 As shown in the embodiment, the vibration-type thick material sealing sewing device includes a vibration shell 1 assembled at the bottom of the sewing machine head, and the sewing machine head is driven to move up and down by other transmission structures of the sewing machine. A vertical sliding cavity 11 is designed in the vibrating shell 1, and a sliding block 2 that can slide up and down is assembled in the sliding cavity 11. The bottom of the sliding block 2 is connected with the lower part of the sliding cavity 11 through a spring 3, so that The bottom of the slider 2 is connected with a sewing needle 4 extending vertically out of the vibrating shell, the upper part of the slider 2 is equipped with a lower magnetic block 21 with vertical magnetic lines of force, and the upper part of the slider 2 is equipped with a Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com