A copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophenylboronic acid

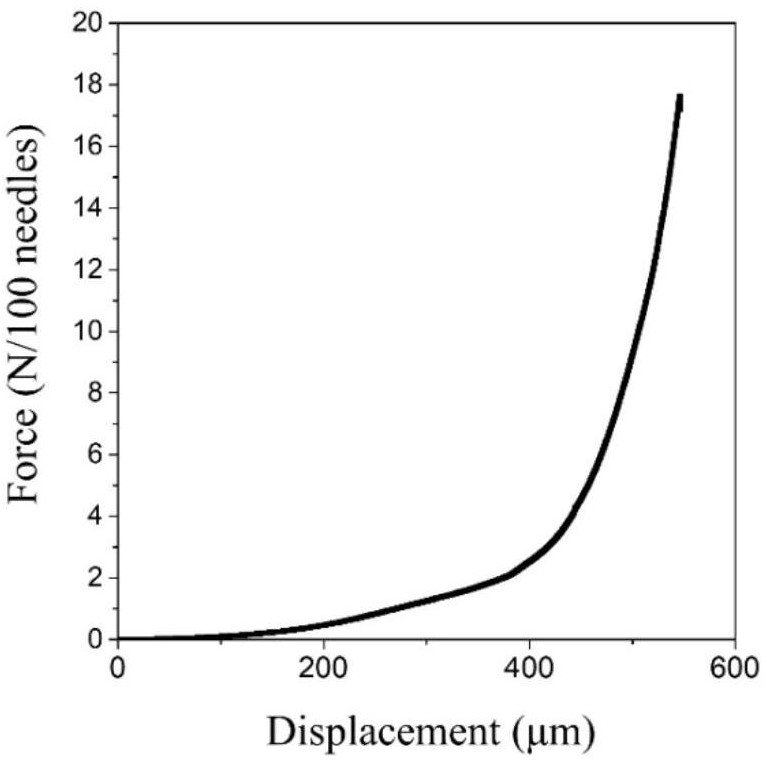

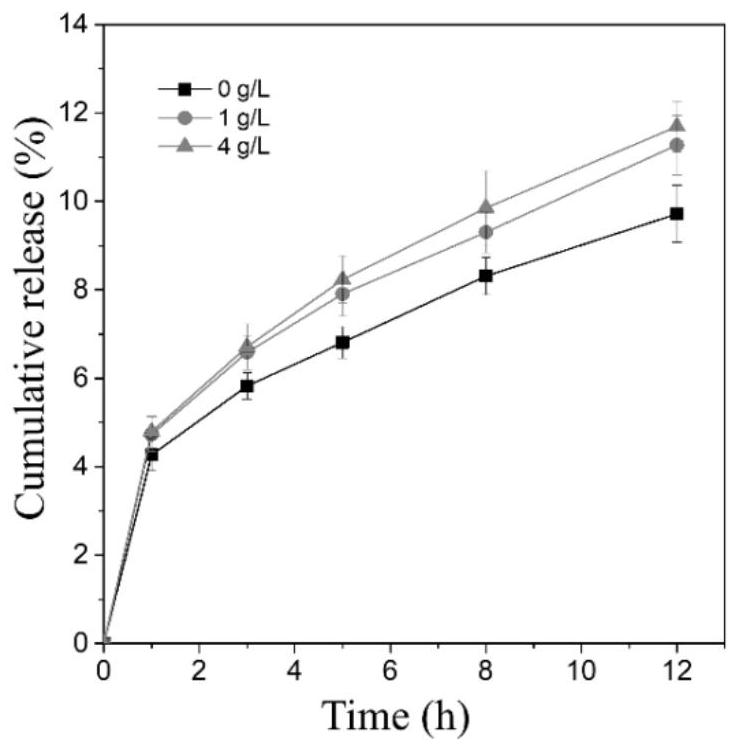

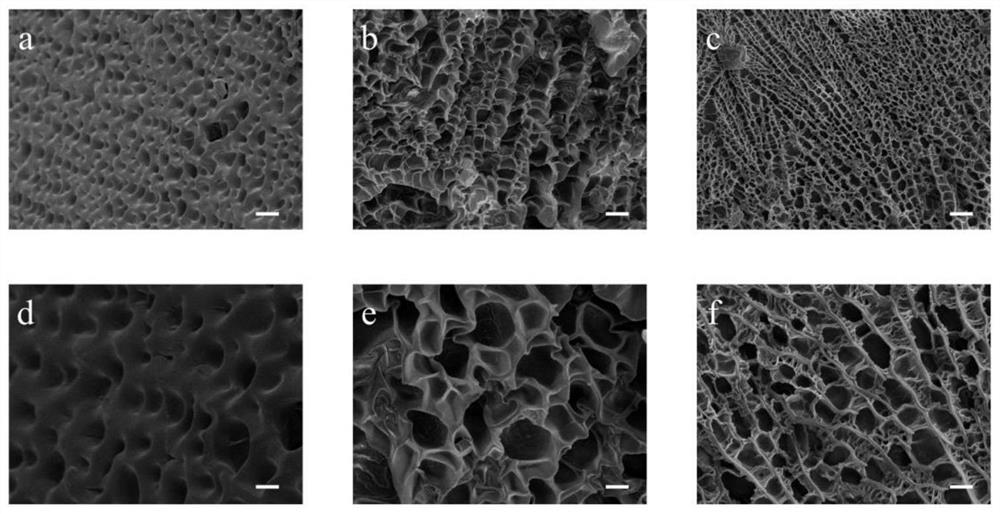

An acrylamide-based phenylboronic acid and acrylamide-based technology, which is applied in the field of copolymer-based sugar-sensitive microneedle patches, can solve the problems of insulin's weak hypoglycemic ability, insulin inactivation, and inhibition, and achieve good biocompatibility and good biocompatibility. Mechanical properties, mild effect of load process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 57.0mg of 3-acrylamidophenylboronic acid, 70.8mg of N-acrylamidoglucose, 272.5mg of N-isopropylacrylamide, 4.5mg of N,N'-methylenebisacrylamide, 2-hydroxy-4' -(2-Hydroxyethoxy)-2-methylpropiophenone 6.9 mg and dimethyl sulfoxide 300 mg were mixed and dissolved to obtain a precursor solution, then added to the microneedle female mold, and centrifuged at 4000 rpm for 60 min. The precursor solution located in the negative mold of the microneedle was initiated by ultraviolet light for radical polymerization, the ultraviolet light wavelength was 365nm, the power was 100W, and the time was 90min. The obtained copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophenylboronic acid was washed with deionized water, and then soaked in an aqueous insulin solution with a mass fraction of 0.2% for loading. After the loading is completed, the copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophenylboronic acid is dried to a constant weight t...

Embodiment 2

[0051] 172.1mg of 3-acrylamidophenylboronic acid, 210.0mg of N-acrylamidoglucose, 500.0mg of N-isopropylacrylamide, 14.1mg of N,N'-methylenebisacrylamide, 2-hydroxy-4' -(2-Hydroxyethoxy)-2-methylpropiophenone 20.2mg and dimethyl sulfoxide 1320mg were mixed and dissolved to obtain a precursor solution, then added to the microneedle female mold, and placed in a negative pressure environment with a pressure of 0.01MPa 1h. The precursor solution located in the negative mold of the microneedle was initiated by ultraviolet light for free radical polymerization, the ultraviolet light wavelength was 350nm, the power was 75W, and the time was 120min. The obtained copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophenylboronic acid was washed with deionized water, and then soaked in an aqueous insulin solution with a mass fraction of 0.2% for loading. After the loading is completed, the copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophen...

Embodiment 3

[0053] 171.0mg of 3-acrylamidophenylboronic acid, 205.7mg of N-acrylamidoglucose, 400.4mg of N-isopropylacrylamide, 15.0mg of N,N'-methylenebisacrylamide, 2-hydroxy-4' -(2-Hydroxyethoxy)-2-methylpropiophenone 19.7 mg and dimethyl sulfoxide 1350 mg were mixed and dissolved to obtain a precursor solution, then added to the microneedle female mold, and centrifuged at 4000 rpm for 60 min. The precursor solution located in the negative mold of the microneedle was initiated by ultraviolet light for radical polymerization, the ultraviolet light wavelength was 365nm, the power was 100W, and the time was 90min. The obtained copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophenylboronic acid was washed with deionized water, and then soaked in an aqueous solution of metformin hydrochloride with a mass fraction of 1% for loading. After the loading is completed, the copolymer-based sugar-sensitive microneedle patch containing 3-acrylamidophenylboronic acid is dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com