A kind of preparation method of multifunctional thin film

A multi-functional, thin-film technology, applied in the fields of botanical equipment and methods, horticulture, plant protection cover, etc., can solve the problem that PVA mulch cannot reach the performance level of PE mulch, film-forming, low permeability and moisture retention, and mulch degradation. Slow speed and other problems, to achieve the effect of smooth surface, high transparency, and improved degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific embodiment one: the preparation method of a kind of multifunctional thin film of present embodiment, it is to carry out according to the following steps:

[0034] 1. Preparation of membrane solution:

[0035]①. Under the condition that the stirring speed is 300rpm~600rpm and the temperature is 50°C~90°C, put the polyvinyl alcohol powder into distilled water and stir for 10min~30min to obtain solution A; the quality of the polyvinyl alcohol powder is the same as The volume ratio of distilled water is 1g:(80~85)mL;

[0036] ②. Under the condition that the stirring speed is 300rpm~600rpm and the temperature is 50℃~90℃, add chitosan powder into solution A, and continue stirring for 5min~15min to obtain solution B; The mass ratio of alcohol powder to chitosan powder is 1:(0.5~4);

[0037] ③. Under the condition that the stirring speed is 300rpm~600rpm and the temperature is 50℃~90℃, add glacial acetic acid dropwise to solution B, and continue stirring for 5min~15m...

specific Embodiment approach 2

[0051] Specific embodiment two: what this embodiment is different from specific embodiment one is: the chitosan powder described in step one 2. is specifically prepared according to the following steps:

[0052] a. Extract chitin from fish scales: wash the fish scales repeatedly to remove surface attachments, put them into an electric heating constant temperature blast drying box to obtain dry fish scales; at room temperature and under stirring conditions, immerse 5g of dry fish scales in a concentration of 1mol / L of HCl solution reacted for 30 minutes, poured out the acid solution after the reaction, washed with water until the washing solution was neutral, then immersed in NaOH with a concentration of 1mol / L, and bathed in water at a temperature of 70°C for 7 minutes, poured out the alkali solution after the reaction , washed twice with water, and then adjusted the solution to be neutral with a pH meter, and filtered with suction to obtain crude chitin; KMnO with a concentra...

specific Embodiment approach 3

[0054] Specific embodiment three: the difference between this embodiment and one of specific embodiments one to two is that the mass ratio of polyvinyl alcohol powder and chitosan powder described in step 1. is 1:(1.5~4). Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

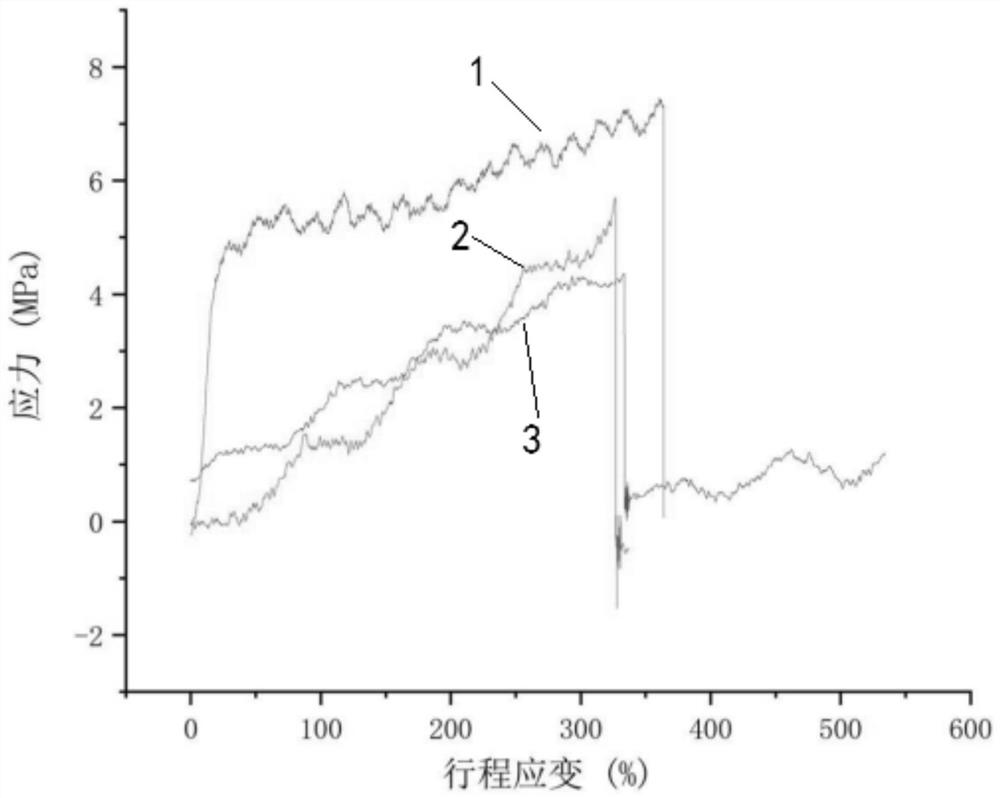

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com