Electronic lock

An electronic lock and lock body technology, applied in the field of electronic locks, can solve problems such as scratches on the surface of door panels, deformation of door panel assembly holes, and inconvenient maintenance, and achieve the effect of reducing waste and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

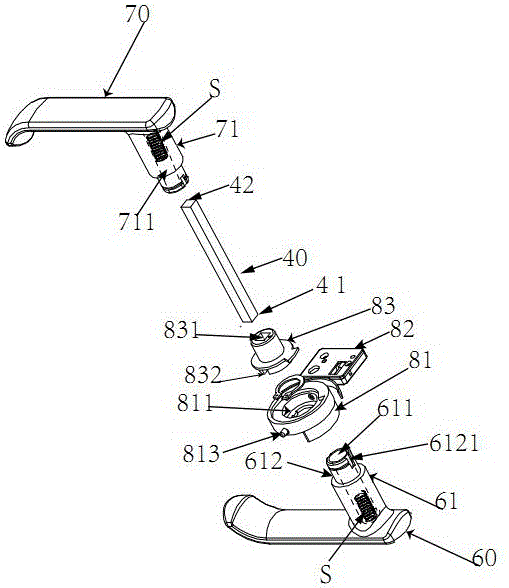

[0032] Such as figure 2 In the first embodiment shown, for the convenience of understanding, this figure only schematically shows the components involved in the present invention, and hides the conventional components of other electronic locks. In the figure, an inner handle 70 and an outer handle 60 are included. Wherein the outer handle 60 includes a joint end 61, from the end surface of the joint end 61 axially extending along the joint end 60 to form a receiving hole 611, the receiving hole 611 is almost equal to the length of the joint end 61, the receiving hole 611 A part of the outer end 41 of the connecting rod 40 can be accommodated. A reduced-diameter portion 612 is formed at the end of the coupling end 61 , and a positioning slot 6121 is formed on a side of the reduced-diameter portion 612 . Between the outer handle 60 and the inner handle 70, a clutch device 80 of an electronic lock is also provided. In this figure, the clutch device 80 is divided into a main r...

Embodiment 2

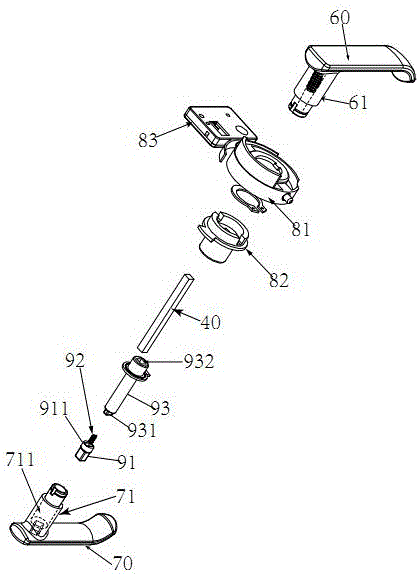

[0037] Such as image 3 As shown, the difference between embodiment two and embodiment one is only that the structure of the inner handle 70 of embodiment two, and an anti-cat's eye device 90 installed in the inner handle 70, including a button 91, a spring 92 and A transmission sleeve 93. A receiving hole 711 is provided in the middle of the inner handle 70, and the receiving hole 711 is a receiving hole with a circular cross section. There is a button hole 712 at the bottom of the receiving hole 711, the button 91 is plugged into the button hole 712, the outer end of the button 91 protrudes to the outer surface of the inner handle 70, and the button 91 has a locking part 911, which can prevent the button 91 from coming out Inner handle 70. In addition, there is a card slot (not shown) on the inner end of the button 91. After the button 91 is installed in the accommodating hole 711, the spring 92 and the transmission sleeve 93 are installed in the accommodating hole 711, wh...

Embodiment 3

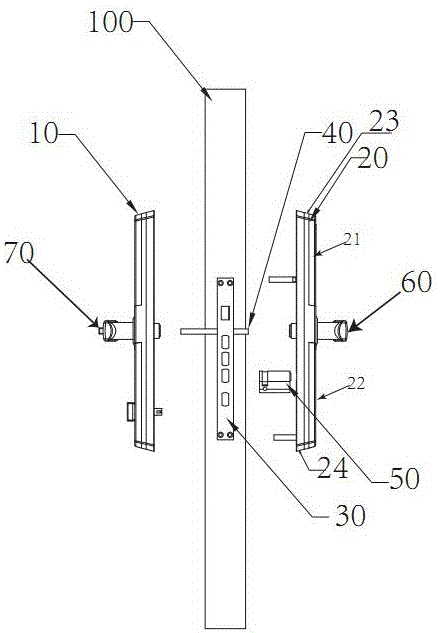

[0039] combine figure 1 and Figure 4 , Figure 5 As shown, the third embodiment is based on the second embodiment, and further describes the specific implementation structure of the outer panel 20 of the electronic lock. The outermost side of the outer panel 20, located above the outer handle 60, is a circuit board box 21 with a password button on the surface, the outer cover 22 is below the outer handle 60, the middle layer is the outer main panel 23, and the innermost layer of the outer panel 20 The side is the bottom plate 24 of the outer panel.

[0040] Such as Figure 4 Shown is an exploded view of the outer panel 20 . Wherein at least one first groove 231 and second groove 232 are formed on the outer surface of the outer main panel 23 . A circuit board box 21 is accommodated in the first groove 231 , and an outer cover 22 is covered above the second groove 232 . The circuit board box 21 is located on the upper left of the outer main panel 23, and includes an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com