Method for performing anchoring and grouting reinforcement inside deep well soft rock gob-side entry retaining

A technology of anchoring and grouting and soft rock, which is applied in the direction of earthwork drilling, installation of bolts, mining equipment, etc., can solve the problems of broken roof of the retaining roadway, high shrinkage rate of the roadway section, and reduce the shrinkage rate of the roadway section, so as to improve the constraint effect , large reinforcement range, improved strength and overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

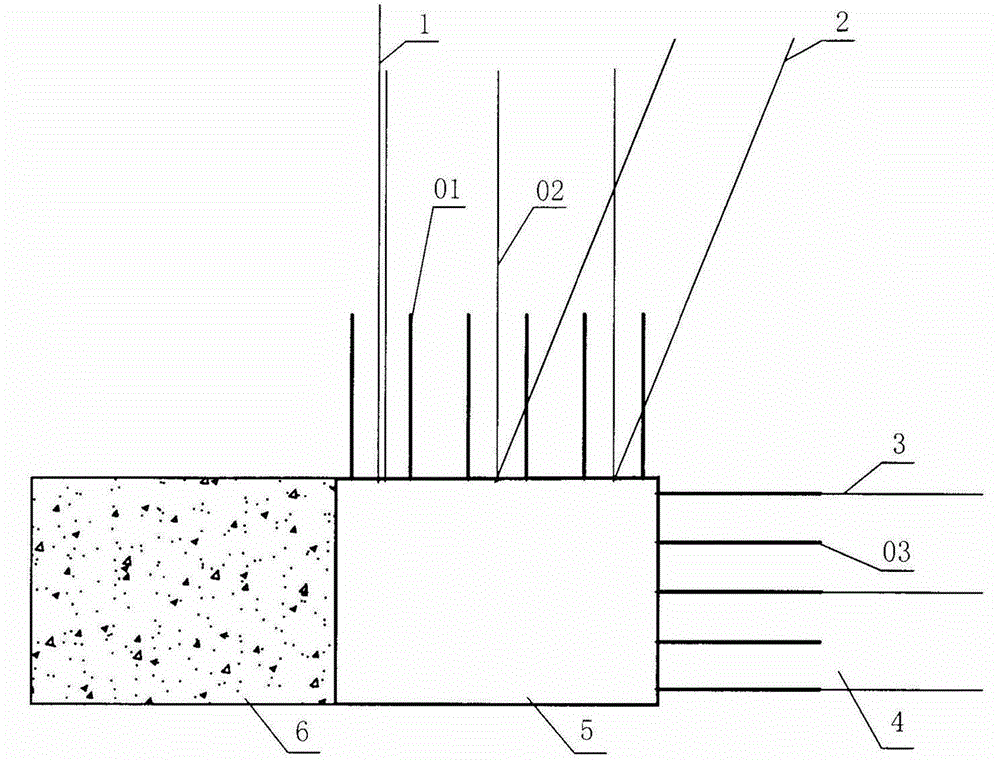

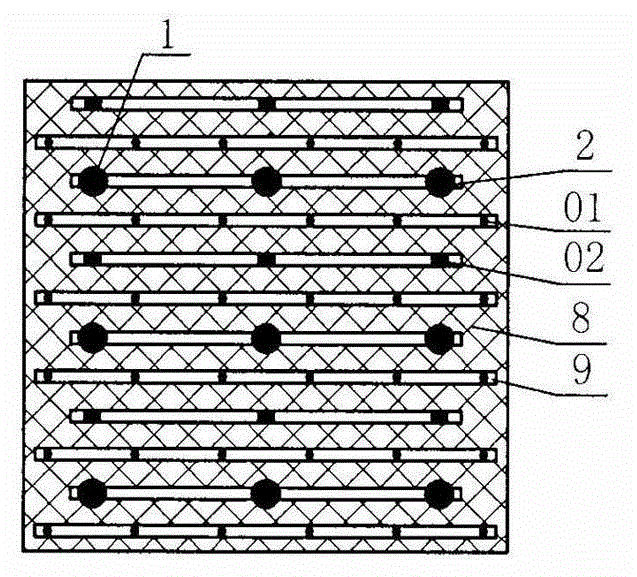

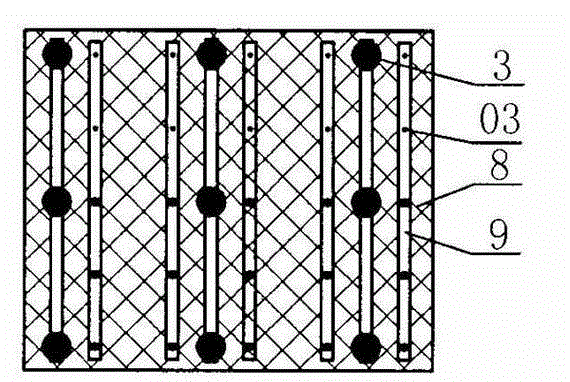

[0031] exist figure 1 , 2 shows the anchoring and grouting reinforcement method in gob-side entry retaining in deep soft rock of the present invention, and the arrangement of hollow anchoring and grouting anchor cables when anchoring and grouting reinforcement is implemented in rectangular gob-side entry retaining. Rectangular or trapezoidal gob-side entry retention is suitable for this implementation method of deep hole high-strength anchor-grouting reinforcement in the entryway.

[0032] figure 1 The gob-side entry 5 in is a rectangular roadway. The original roof bolt 01, the original roof anchor cable 02, and the original roadway side anchor 03 are the original support of the gob-side entry roadway during the excavation stage. After the roadway is used as the gob-side entry 5, one side of the mining face is referred to as the mining side 6, and the concrete filling body 6 poured on the mining side after mining is used as the roadside filling body support constructed on t...

Embodiment 2

[0049] exist Figure 4 , 5 The method of the present invention shows the arrangement of the hollow anchoring and anchoring cables when the semicircular arched gob-side entry retaining roadway 7 is implemented with high-strength anchoring and grouting reinforcement for deep holes in the roadway.

[0050] exist Figure 4 , 5 In the semicircular arched gob-side entry retention 7 shown, the original roof anchor cable 04 and the original roadside anchor cable 05 are the original support of the roadway during the excavation stage. The roadway is used as the back of the gob-side entry retention 7 , and its mining side is supported by the concrete filling body 6 after mining, and is the side of the mining side of the gob-side entry retention 7 . There is no hollow anchor anchor cable support arranged on this side. The original roof anchor cable 04 and the original roadside anchor cable 05 are ordinary steel strand anchor cables.

[0051] exist Figure 4 , 5 As shown in the 7th ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com