A Supporting Method for Pre-excavation Single Retraction Channel in Fully Mechanized Mining Face

A technology of retraction channel and fully mechanized mining face, which is applied in the field of pre-excavation single retraction channel support of coal mine fully mechanized mining face. The effect of economical cost reduction and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

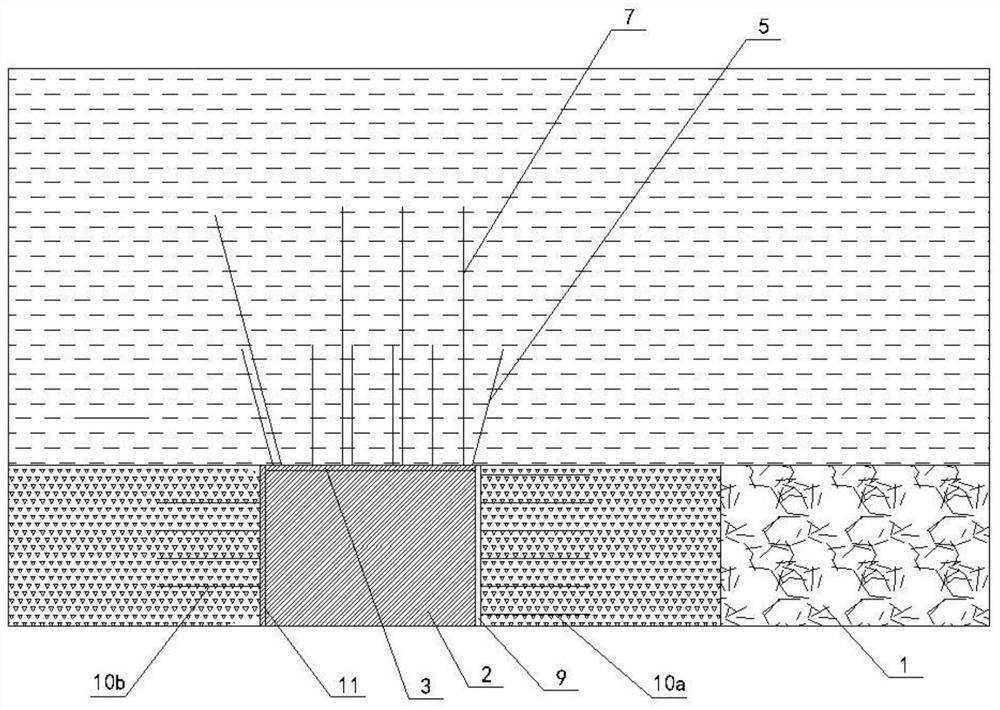

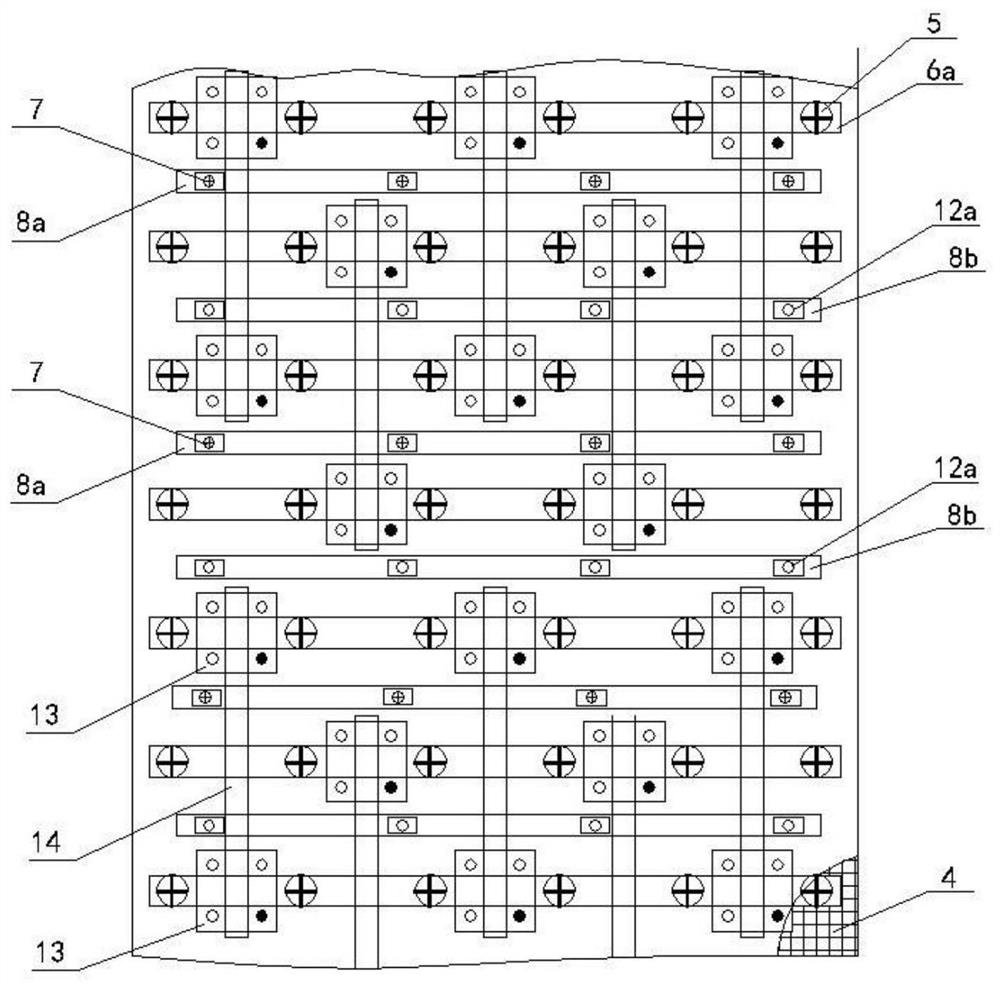

[0026] see figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, the pre-excavation single-retraction channel support method of fully mechanized mining face is carried out according to the following steps:

[0027] Step 1. Before the working face 1 advances to 300m of the production stop line, complete the initial support of the withdrawal channel 2 as follows:

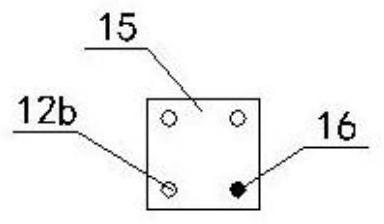

[0028] Set the cross-section of the retraction channel 2 as a rectangle, such as 4500mm×4300mm. During the excavation of the retraction channel 2, set up the joint support of the anchor cable net. The joint support of the anchor cable net includes: laying the metal mesh 4 on the surface of the roadway roof 3 (Such as figure 2 As shown), the roof anchor rods 5 are combined into rows by the horizontal roof steel strips 6a; on the roadway roof 3, a row of roof primary support anchor cables 7 is arranged every two rows of transverse roof steel strips 6a, and the roof primary support anchor cables 7 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com