Air compressor

A technology of air compressor and compression mechanism, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of no intersection, adverse effects of use, transportation, storage, and occupying a large space, so as to achieve convenient and stable use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

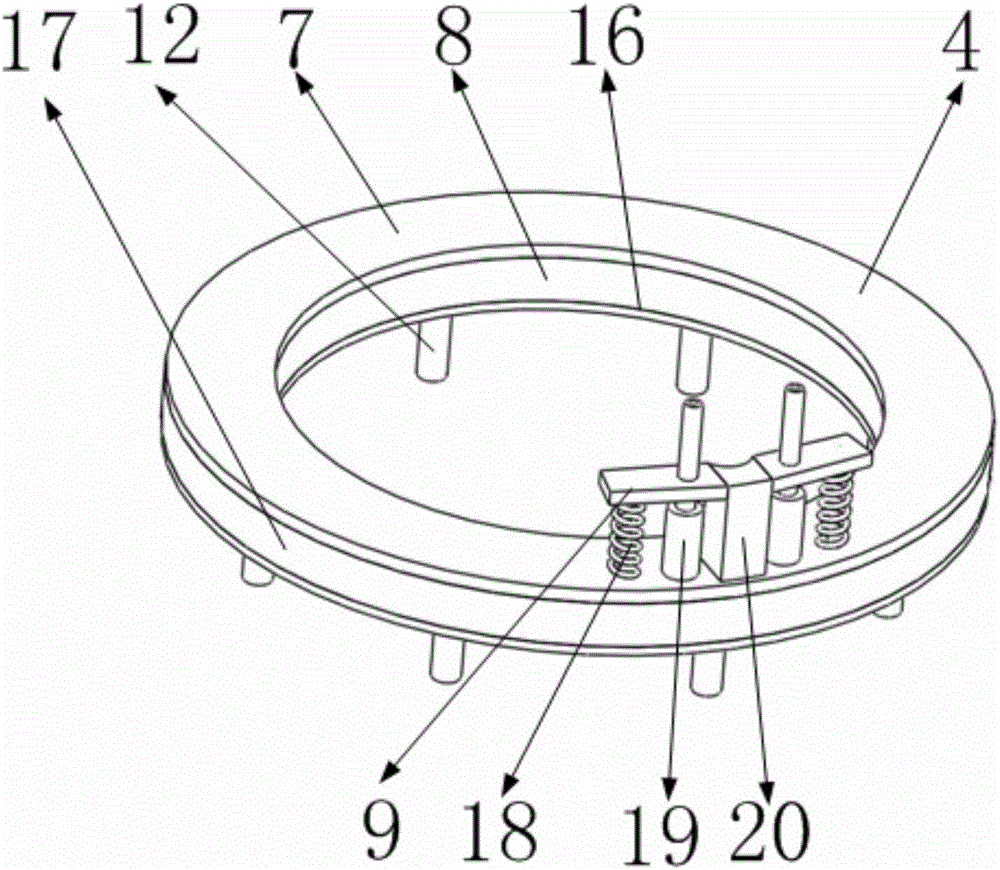

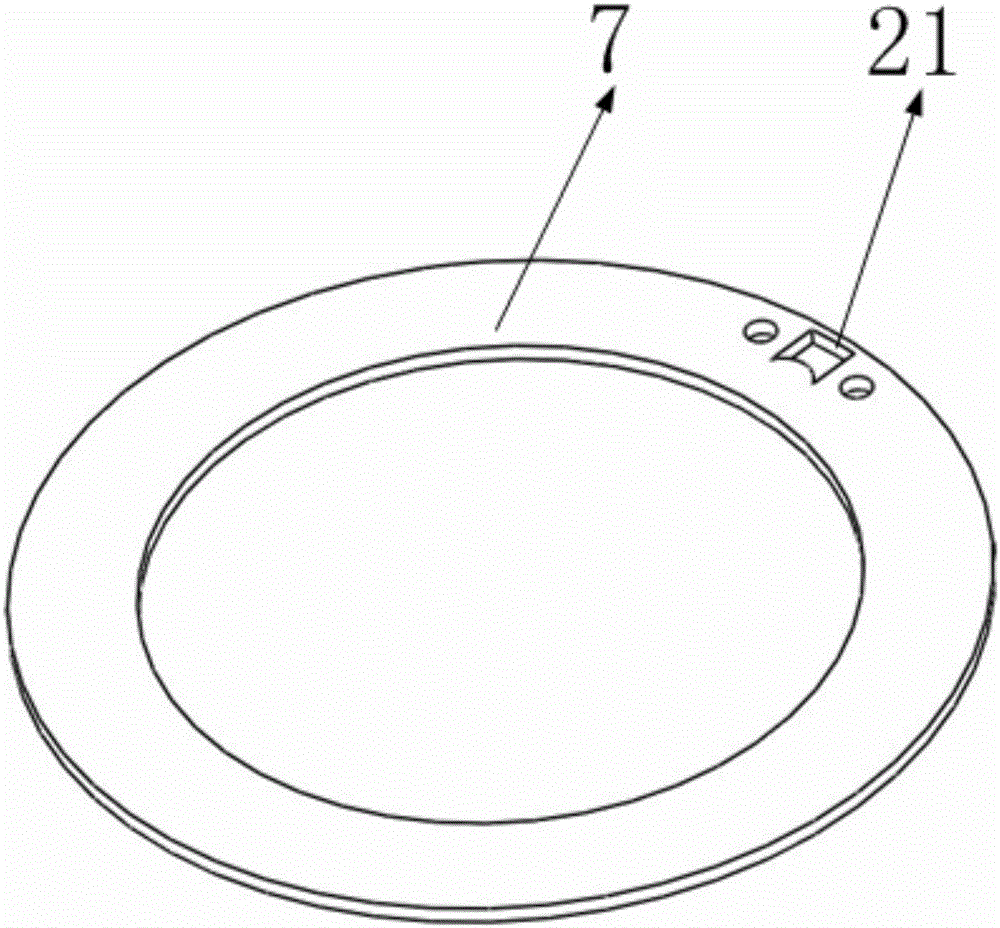

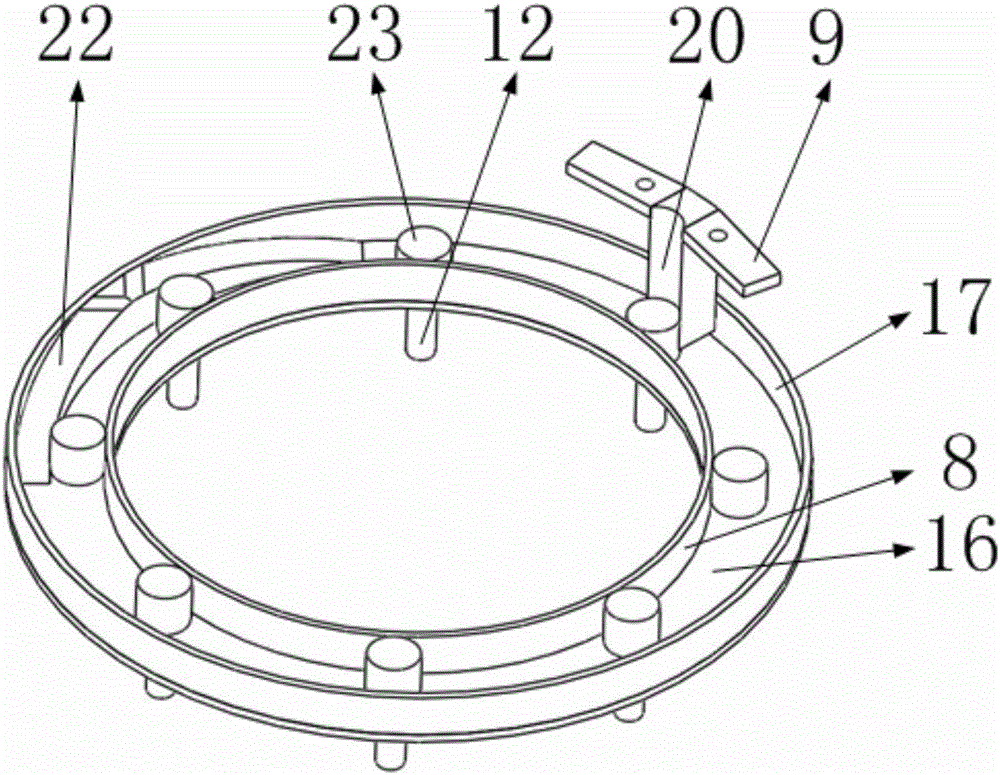

[0027] Such as Figure 7 , 8 As shown, it includes a support column, a base, an air tank inlet and outlet valve, a compression mechanism, an air tank, a motor shaft, a motor, a sun gear, and a first gear, among which such as Figure 8 As shown in , the compression mechanism is installed on the base through three supporting columns evenly distributed in the circumferential direction, as shown in Figure 7 As shown, the air tank is installed on the upper side of the compression mechanism, as shown in Figure 11 As shown, two air tank inlet and outlet valves are installed on the top of the air tank, and the motor is installed in the center of the compression mechanism as shown in Figure 9 As shown, the thickness of the motor is the same as that of the compression mechanism, such as Figure 8 As shown, the central gear is installed on the side of the motor facing the base through the motor shaft, and meshes with the first gear on the compression mechanism.

[0028] Such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com