Sliding Vane Air Compressor

An air compressor and sliding vane technology, applied in the field of air compressors, can solve the problems of deviation in coaxiality, complex structure, large volume, etc., and achieve the effects of weight reduction, volume reduction, and overall weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

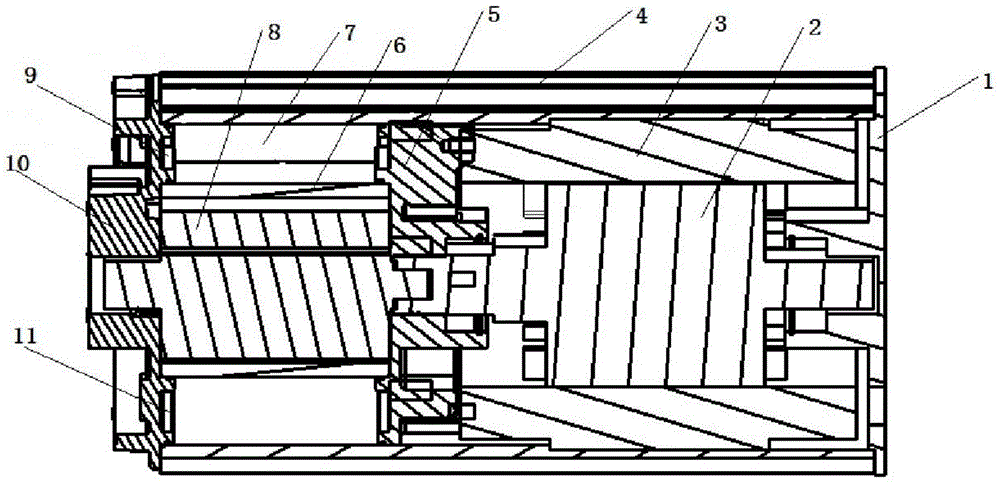

[0013] In order to solve the problems of complex connection structure, many accessory parts, large volume and heavy weight in the existing air compressor, the present invention provides a sliding vane air compressor, which includes a cylindrical shell 4, sealed and fixed on the shell 4 The inner cover 5, the compressor end cover 10 and the motor end cover 1 fixedly installed at both ends of the housing 4, the motor assembly and the compressor assembly installed on both sides of the inner cover 5 of the housing 4, the motor assembly includes The motor stator 2 installed on the inner wall of the housing 4 and the motor rotor 3 installed coaxially with it, one end of the main shaft of the motor rotor 3 is set through the through hole in the middle of the cover 5, and the compressor assembly includes a motor installed on the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com