Air channel structure for controlling piston rod action of eliminating air cylinder

A technology for removing cylinders and piston rods, applied in the direction of fluid pressure actuating devices, servo motors, servo motor components, etc., can solve the problems of limiting the air discharge speed, shortening the service life of the removing cylinder, and the inability of the piston rod to reset quickly. The effect of reset time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

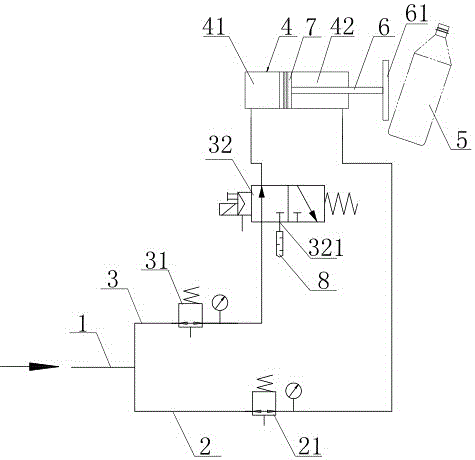

[0013] Such as figure 1 As shown, the gas path structure for controlling the movement of the piston rod of the rejecting cylinder includes: an air intake pipe 1, the inlet end of the air intake pipe 1 is connected with the compressed air source, and the outlet end of the air inlet pipe 1 is connected in parallel with the first pipeline 3 and the second pipeline. The second pipeline 2 and the first pipeline 3 are sequentially provided with a first pressure reducing valve 31 and a two-position three-way electromagnetic reversing valve 32 along the input direction of the compressed air. The two-position three-way electromagnetic reversing valve is a kind of Common automation components used to control the direction of fluid movement. The second pipeline 2 is provided with a second pressure reducing valve 21 . In this embodiment, both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com