Multi-stage damping shock absorber

A shock absorber and damping technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of shock absorber damage, shock absorber scrapping, low reliability, etc., to prevent vibration transmission , Prevent rigid damage, good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

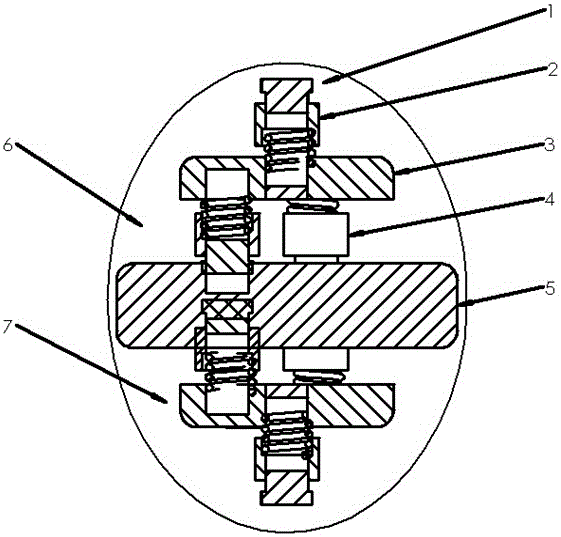

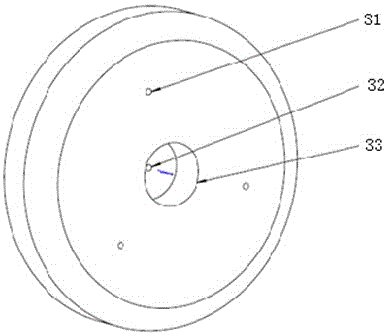

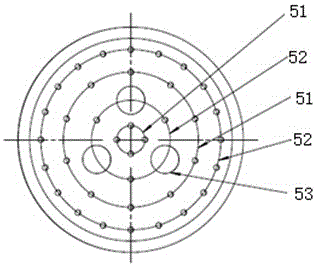

[0015] The structure diagram of the present invention is as figure 1 As shown, the multistage damping shock absorber of the present invention includes an encapsulated elastic shell 1, a primary buffer plunger 2, a primary shock absorbing damping disc 3, a secondary buffer plunger 4, a secondary porous damping disc 5, The first viscous oil 6 and the second viscous oil 7, wherein the first-level buffer plunger 2, the first-level shock-absorbing damping disc 3, the second-level buffering plunger 4, and the second-level multi-hole damping disc 5 are all installed in the package elastic In the cavity provided by the shell 1, the secondary buffer plunger 4 is installed on the secondary porous damping disc 5, the primary shock-absorbing damping disc 3 is mounted on the secondary buffer plunger 4, and the primary buffer plunger 2 Installed on the first-stage shock-absorbing damping disc 3, the second viscous oil 7 is placed at the bottom of the cavity of the encapsulating elastic shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com