Safe and energy-saving burning device

A combustion device, a safe technology, applied in the burner, combustion type, combustion control and other directions, can solve the problems of safety, reliability to be improved, no gas dilution function, gas leakage, etc., to improve the scope of application and application scenarios , Eliminate the potential risk of fuel leakage, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

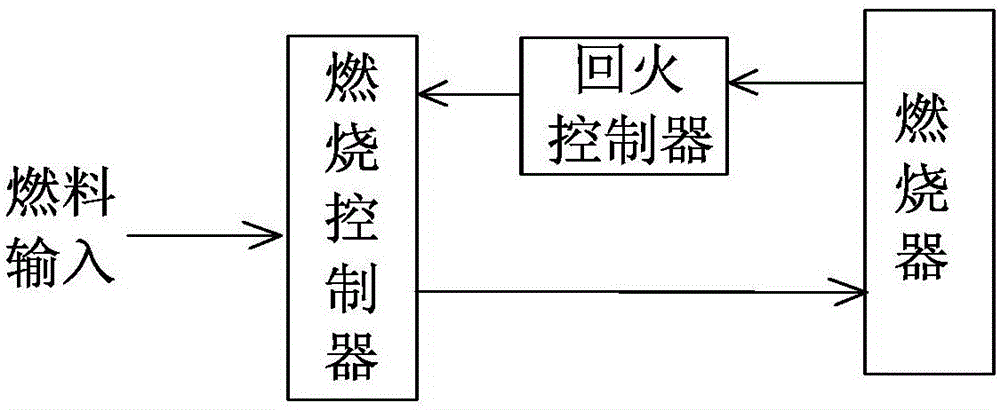

[0027] like figure 1 As shown, the present invention proposes a combustion device with high safety, uniform mixing and wide adaptability, including a combustion controller and a burner connected through a fuel conduit, and a tempering control device arranged between the combustion controller and the burner device.

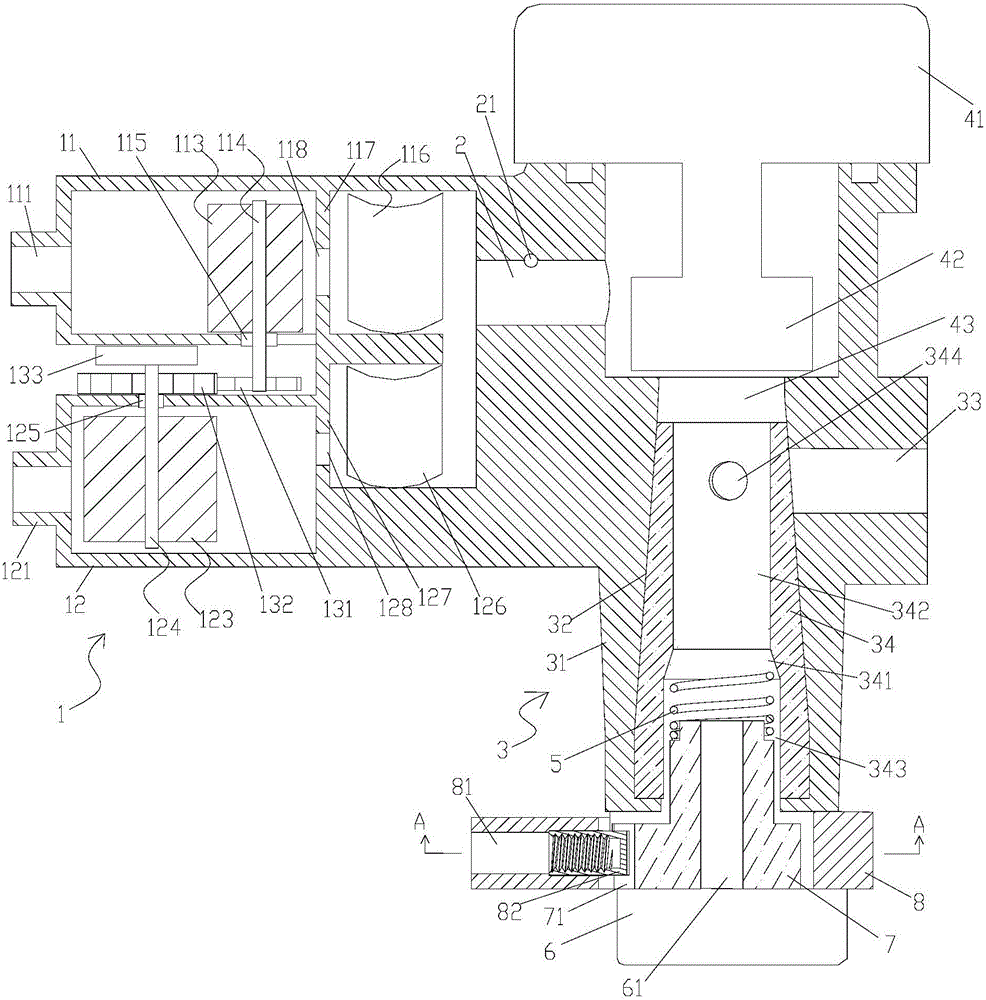

[0028] combine figure 2 and image 3 As shown, the combustion controller includes a fuel mixing part, a fuel control switch, a fuel output switch and an output switch state detection part connected in sequence.

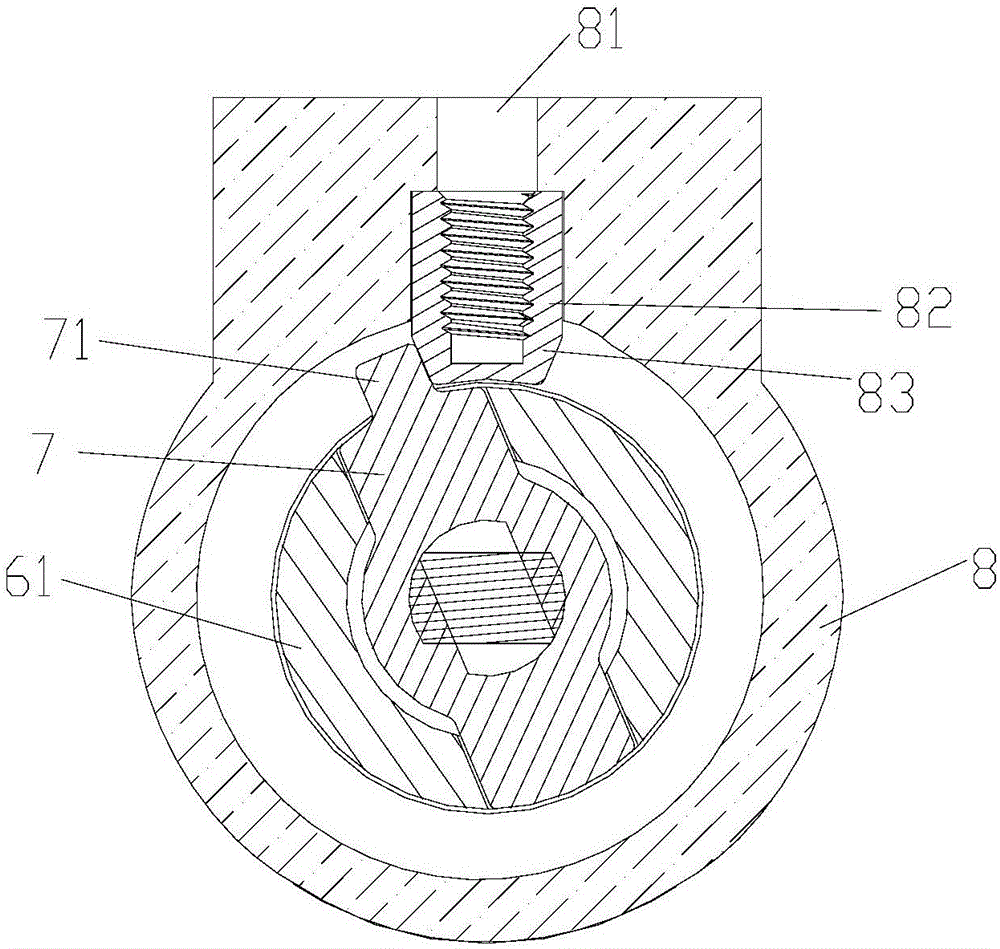

[0029] Wherein, the fuel mixing part includes an input part 1 having a plurality of input channels and a mixing chamber 2 communicating with each input channel. Take the input unit 1 with two input channels as an example for further description. The input part 1 includes: a first input channel 11 with a first input interface 111 for the first fuel (such as the first fuel is coal gas, natural gas, petroleum gas, diesel oil or gasoline, etc.) to enter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com