Heat energy area heating control system and method

A district heating and control system technology, applied in heating systems, hot water central heating systems, heating fuels, etc., can solve the problems of low efficiency, unsatisfactory control logic and other problems in the heating system, and achieve heating efficiency The effect of improving and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

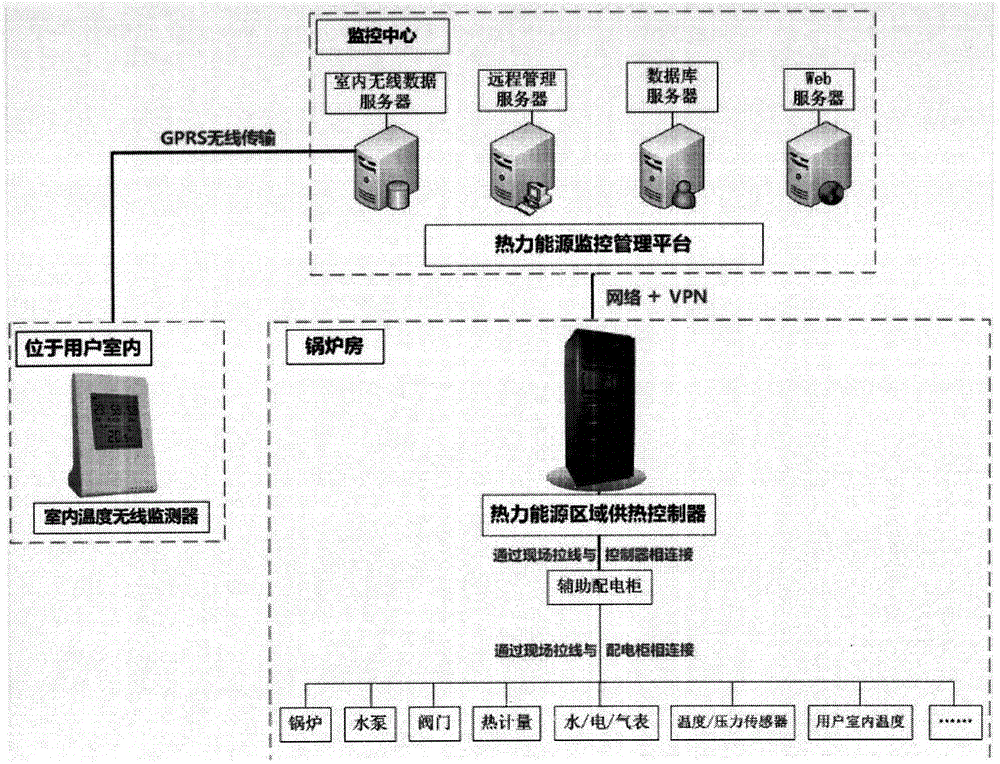

[0027] Such as figure 1 As shown, a thermal energy district heating control system includes hardware equipment and software equipment. The hardware equipment includes gas boilers, auxiliary power distribution cabinets, thermal energy district heating controllers and indoor temperature wireless monitors. The software equipment includes thermal energy Monitoring and management platform;

[0028] in,

[0029] The gas boiler provides heat for the overall system;

[0030] The thermal energy monitoring and management platform summarizes the building information and calculates the real-time heating load demand of the building. The background horizontally / vertically compares the management experienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com