Single-pipe vertical heat collector

A heat collector and vertical technology, applied in the field of solar water heaters, can solve problems such as high cost, lower water tank insulation performance, and large brackets, and achieve the effects of convenient installation, saving bracket costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

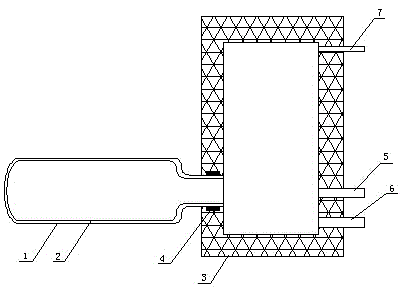

[0013] exist figure 1 In the single-tube vertical heat collector, one end of the outer glass tube 1 and the inner glass tube 2 of the vacuum heat collecting tube are welded to each other to form the open end of the vacuum heat collecting tube, and the other ends of the outer glass tube 1 and the inner glass tube 2 are respectively sealed to form The free end is coated with a heat-absorbing film on the outer surface of the inner glass tube 2. The outer diameters of the inner glass tube 2 and the outer glass tube 1 at the open end are respectively 58 mm and 70 mm. The average of the inner glass tubes The outer diameter is 200mm, and the length of the outer glass tube is 2000mm. The open end of the vacuum heat collecting tube is inserted into the side of the bottom of the water tank 3, and a silica gel sealing ring 4 is arranged between the water tank 3 and the vacuum heat collecting tube. There are water inlet pipe 5, water outlet pipe 6 and exhaust pipe 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com