Three-phase interactive vortex heat exchanger and strengthened heat transfer device

An enhanced heat transfer and interactive technology, which is applied in the field of three-phase interactive eddy current heat exchangers and enhanced heat transfer devices, can solve the problems of insufficient improvement of heat transfer efficiency, low heat transfer efficiency, and complicated processing and production, and achieve The effect of saving material, avoiding the formation of scale, and increasing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

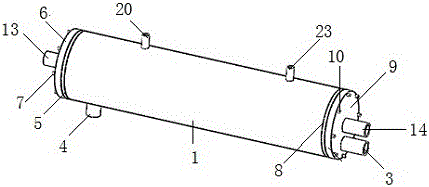

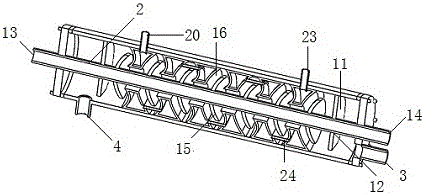

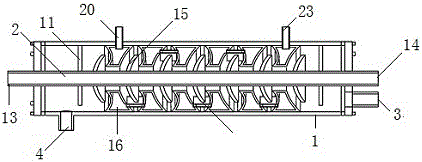

[0031] Specific implementation mode one: combine Figure 1-11As shown, it includes a cylinder body 1, a heat exchange tube 2, a second phase inlet 3, and a second phase outlet 4; one end of the cylinder body 1 is bolted to the first flange 6 through a first gasket 5; wherein the first gasket 5 is closely attached to It fits between the cylinder body 1 and the first flange 6; eight first bolts 7 are evenly distributed along the circumferential direction of the first flange 6; the other end of the cylinder body 1 passes through the second gasket 8 and the second The flange 9 is bolted; wherein the second gasket 8 is tightly fitted between the cylinder body 1 and the second flange 9; eight second bolts 10 are evenly distributed along the circumferential direction of the second flange 9; There are two baffle tube plates 11 inside the cylinder body 1; one of the baffle tube plates 11 is welded on the inner wall of the cylinder body 1 on the side of the first flange 6; the second ba...

specific Embodiment approach 2

[0033] Embodiment 2: Two-phase heat exchange is performed, the hot fluid / cold fluid is passed from the first phase inlet 13 to the heat exchange tube 2, and the cold fluid / hot fluid is passed from the second phase inlet 3 to the shell side.

specific Embodiment approach 3

[0034] Specific embodiment three, two-phase heat exchange is carried out, the hot fluid / cold fluid is passed into the shell side from the second phase inlet 3, and the cold fluid / cold fluid is passed into the cavity of the enhanced heat exchange device from the third phase inlet pipe 20 thermal fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com