Muzzle angle vibration response test method and system

A technology of vibration response and test method, which is applied in the direction of weapon testing, weapon accessories, offensive equipment, etc., can solve problems such as large errors, errors in simulation calculation results, and complexity, and achieve the effect of improving test efficiency and simplifying the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

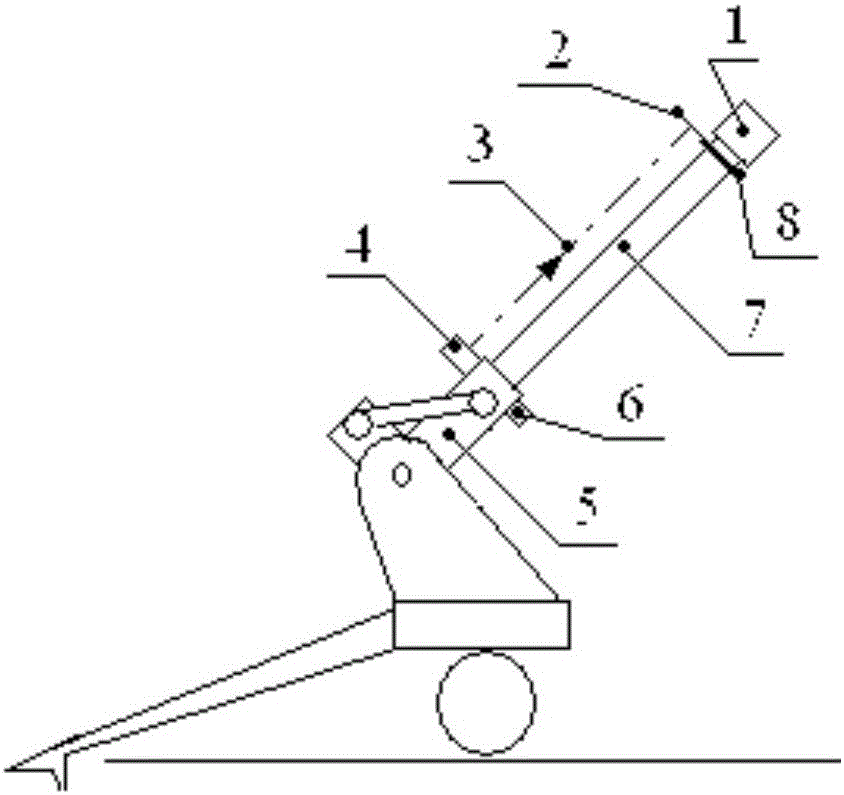

[0049] The following embodiments illustrate the method of the present disclosure with reference to the accompanying drawings.

[0050] In one embodiment, a kind of muzzle angle vibration response testing method is provided, and described method comprises the following steps:

[0051] S100, installing the test component:

[0052] A muzzle hoop is fixed on the outer surface of the muzzle, and a plane mirror is fixedly connected on the muzzle hoop, the plane mirror surface is perpendicular to the axis of the barrel, and the mirror faces backward;

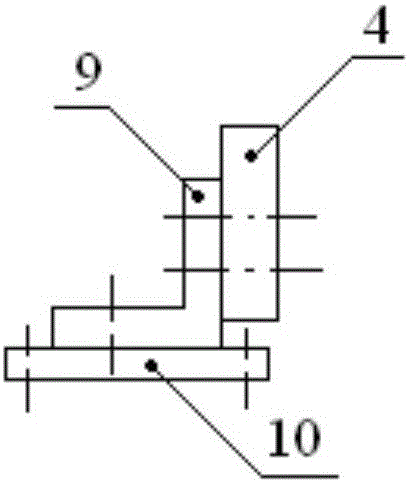

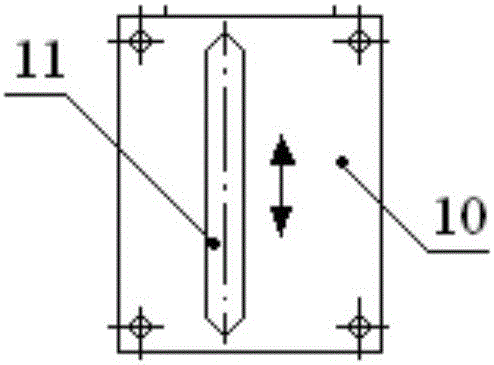

[0053] A detector assembly is connected directly above the front end of the artillery cradle through a mounting seat. The displacement sensitive element used in the detector assembly is a two-dimensional position sensitive sensor PSD, including a laser and a detector. Adjust and fix the position of the detector assembly so that the detection The laser beam emitted by the laser in the laser component is directly irradiated into the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com