Fiber laser beam quality measurement method base on photoelectric detector and CCD camera

A technology of photodetector and beam quality, applied in the direction of testing optical performance, etc., can solve the problems of low precision, limited scope of application, complicated implementation methods, etc., and achieve the effect of convenient operation, simple and correct principle, and easy optical path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

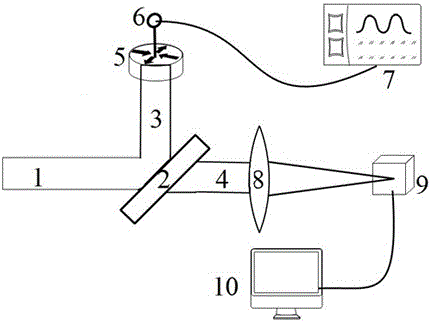

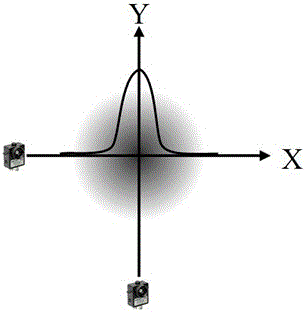

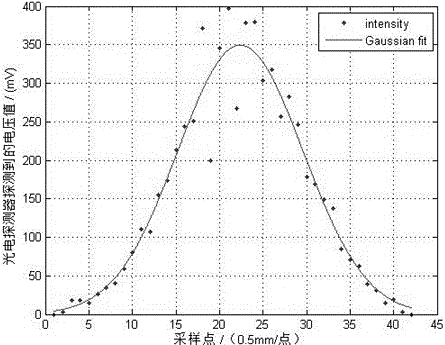

[0043] as attached figure 1 As shown, first level the optical axis of the measured beam 1, put the beam splitter 2 in the optical path, and divide the measured beam into two parts: the reflected beam 3 and the transmitted beam 4, which are used to measure the near-field and far-field of the beam respectively. . For the measurement of the near field of the beam, we use a photodetector 6 placed on a three-dimensional adjustment stage 5 with a helical micrometer. The photodetector 6 can convert the detected light intensity information into voltage information, which can be displayed in real time by the oscilloscope 7, and the voltage value displayed by the oscilloscope 7 can be equivalent to the light intensity value. The specific test method is attached figure 2 shown. By adjusting the helical micrometer in the X direction of 5, the photodetector can be placed at different positions of the measured beam along the X direction passing through the center of the beam, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com