On-line monitoring and verification device for distributed capacitive equipment and on-site verification method based on the device

A technology of capacitive equipment and calibration devices, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problem of large disassembly workload that is not suitable for the development of calibration work of on-line monitoring devices, leakage current sampling units and reference voltage sampling Units are far apart, reference voltage and reference current cannot be provided, etc., to reduce equipment risks and personal safety risks, improve on-site calibration accuracy, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

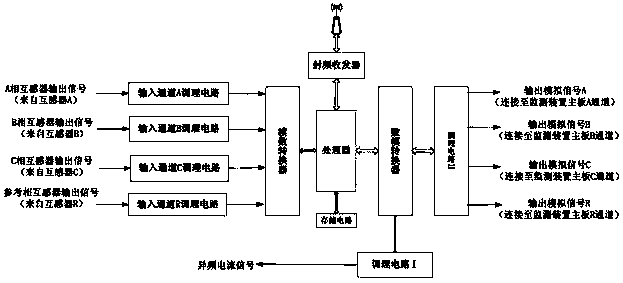

[0055] Such as figure 1 As shown, this embodiment is an online monitoring and verification device for distributed capacitive equipment, which is characterized in that it includes:

[0056] The processor is used to control the operation of the radio frequency transceiver, storage circuit, analog-to-digital converter and digital-to-analog converter, and can analyze and process data;

[0057] The radio frequency transceiver is connected with the processor for communication with the host computer and timing;

[0058] The storage circuit is connected with the processor and is used for storing and processing and analyzing the data collected by the analog-to-digital converter;

[0059] An analog-to-digital converter, connected to the processor, is used to convert the collected analog signal into a digital signal for analysis and processing;

[0060] A digital-to-analog converter, connected to the processor, is used to convert digital signals into analog signals to generate power freq...

Embodiment 2

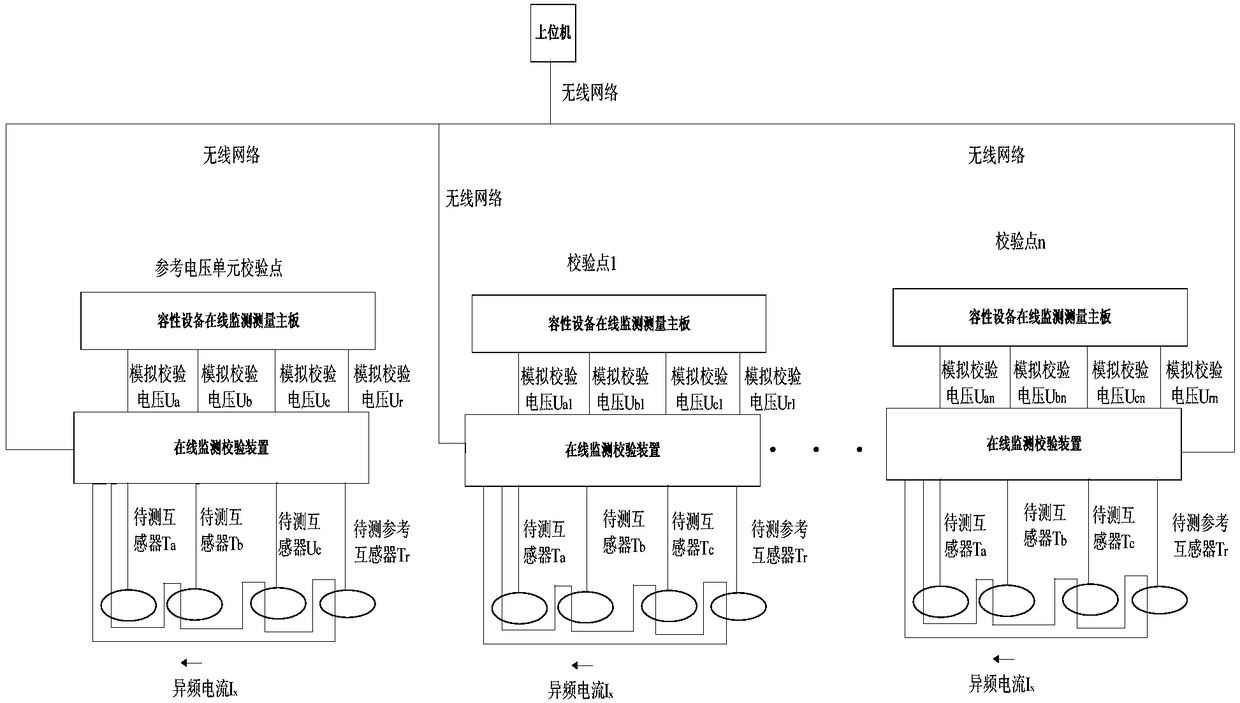

[0071] Such as figure 2 As shown, this embodiment is an on-site verification method of a distributed capacitive equipment online monitoring and verification device. The method uses a distributed capacitive equipment online monitoring and verification device. This verification method includes a small current transformer calibration The verification part and the measurement board verification part include the following steps:

[0072] Step 1: Connect the distributed capacitive equipment online monitoring and verification device to the capacitive equipment online monitoring device;

[0073] Small current transformer calibration part:

[0074] Step 2: Using the distributed capacitive equipment online monitoring and verification device to obtain the error data of the small current transformer of the capacitive equipment online monitoring device;

[0075] Further, the step 2 is further specifically: the distributed capacitive equipment online monitoring and verification device ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com