Method for cutting sectors for tyre moulds and semi-finished element for supplying sectors of a mould for moulding tyres

A technology for molding elements, cutting methods, applied in the field of molding elements for making molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] definition

[0048] "Tire" means an elastic tread of all kinds, whether or not it is subjected to internal pressure.

[0049] "Tread" of a tire means a quantity of rubber compound delimited by side surfaces and two main surfaces, one of which is intended to come into contact with the ground when the tire is running.

[0050] "Tread pattern" means the surface and volume arrangement of the rubber compound at the outer surface of the tyre, intended to provide contact with the running surface and shaped so as to enable adjustment of the running properties of the tyre. The tread pattern also allows the tread or some other area of the tire, such as the sidewall, to be given an attractive appearance.

[0051] "Mold" means a collection of separate molding elements which, when brought together, enable the definition of an annular molding space in which a tire may be vulcanized and molded.

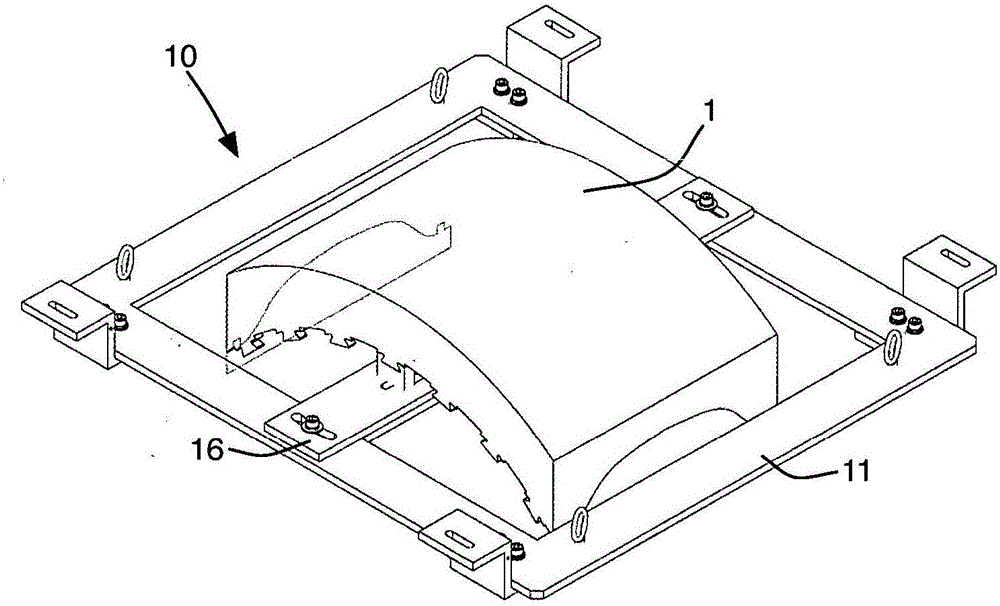

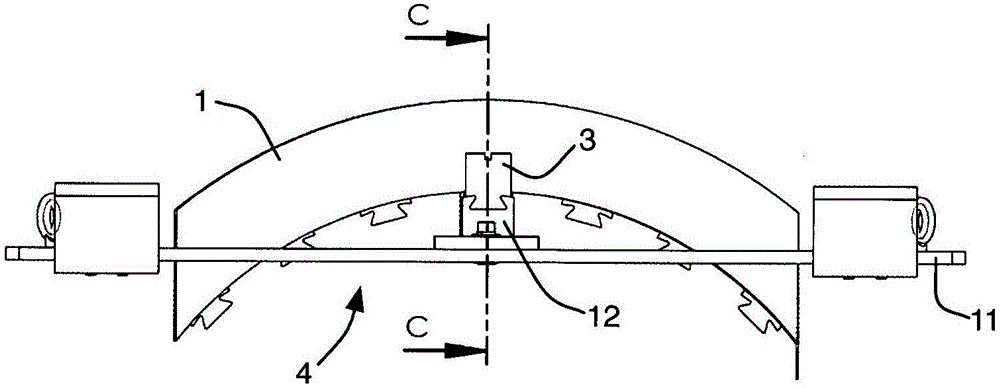

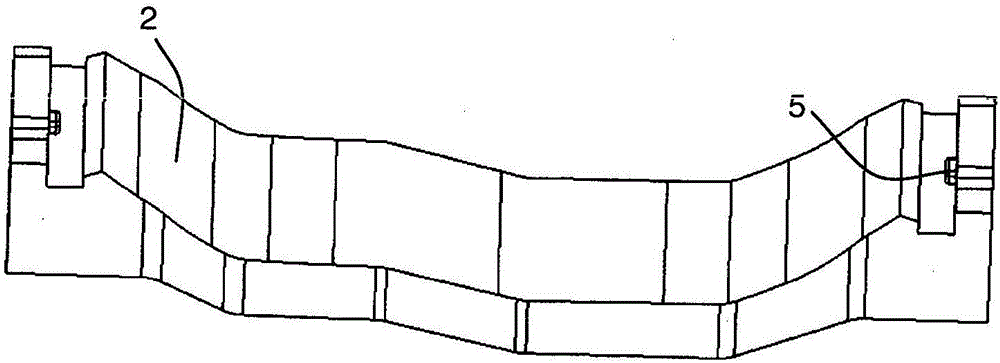

[0052] image 3An example of section 2 is shown for use in a mold for molding and vu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com