Pt/WO3-CNTs (carbon nanotubes) catalyst prepared with hydro-thermal synthesis method

A hydrothermal synthesis method and catalyst technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst activation/preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

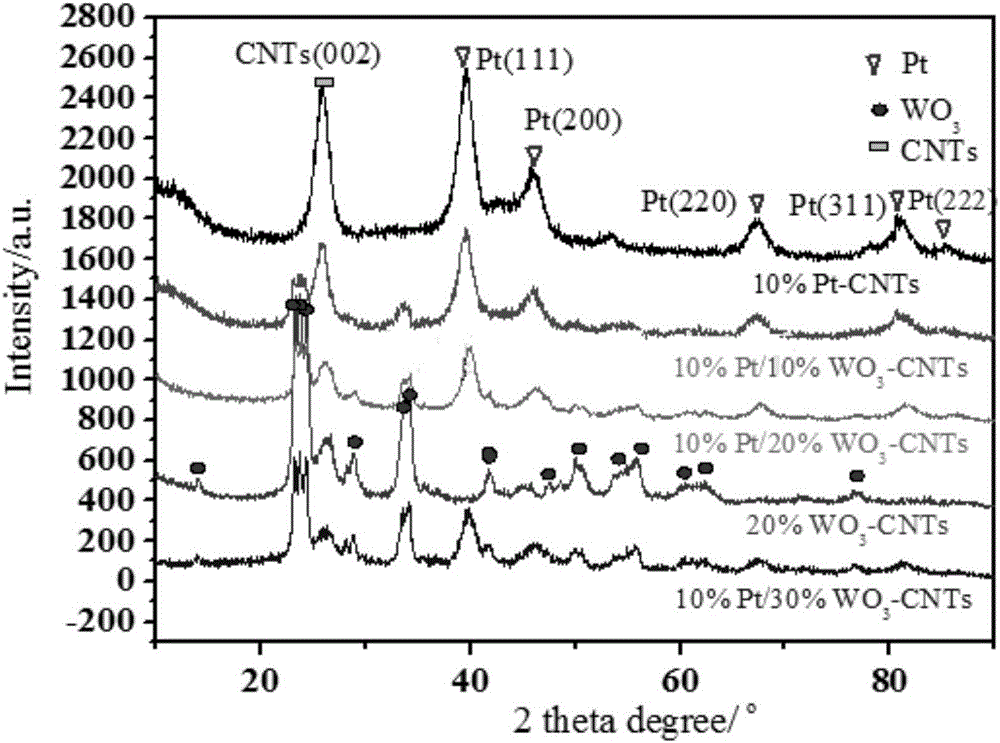

[0038] 1.1 WO 3 - Preparation of CNTs carrier

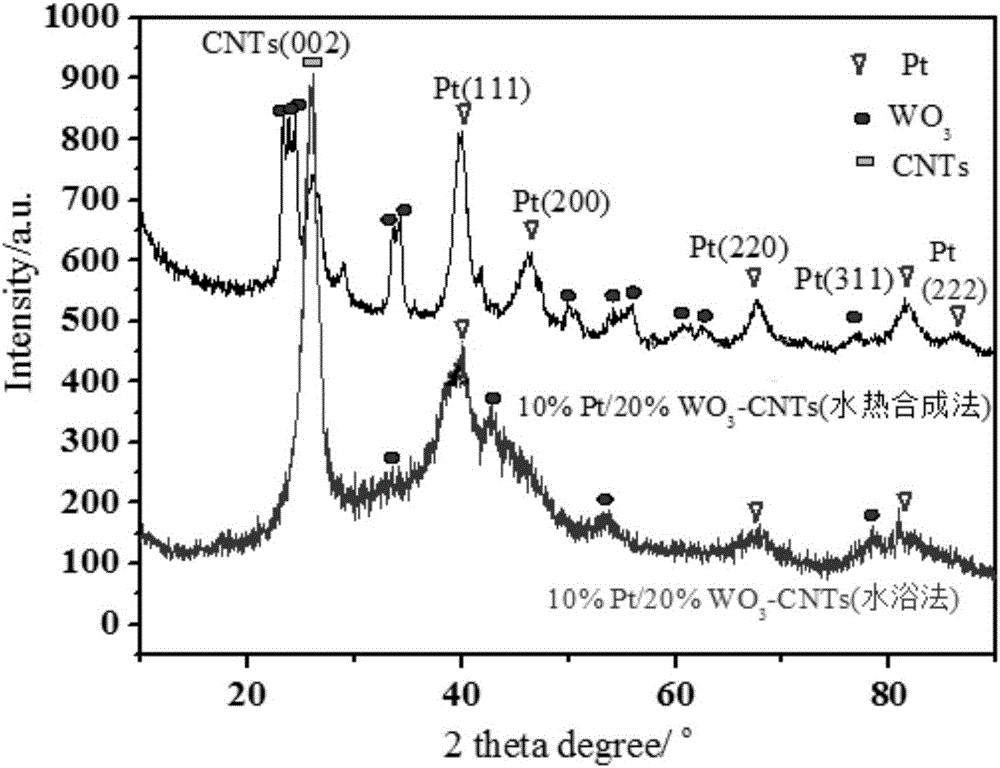

[0039] 1) Water bath method: add 20mL deionized water to a 50mL beaker, then add 5.0000gAMT, stir to dissolve, then add 150mgCNTs, sonicate with an ultrasonic instrument for 20min, transfer to a three-necked flask, add magnets and place in a water bath at 100°C Heating under reflux for 12h. After the end, use a sand core funnel to filter under reduced pressure, and wash with the filtrate for 2 to 3 times, place the sample in a blast drying oven at 90°C for drying, and after drying, put the sample in a crucible and place it in a muffle furnace to raise the temperature to 500 ℃, heat preservation and calcination for 6h, so that 20% WO 3 - CNTs carrier.

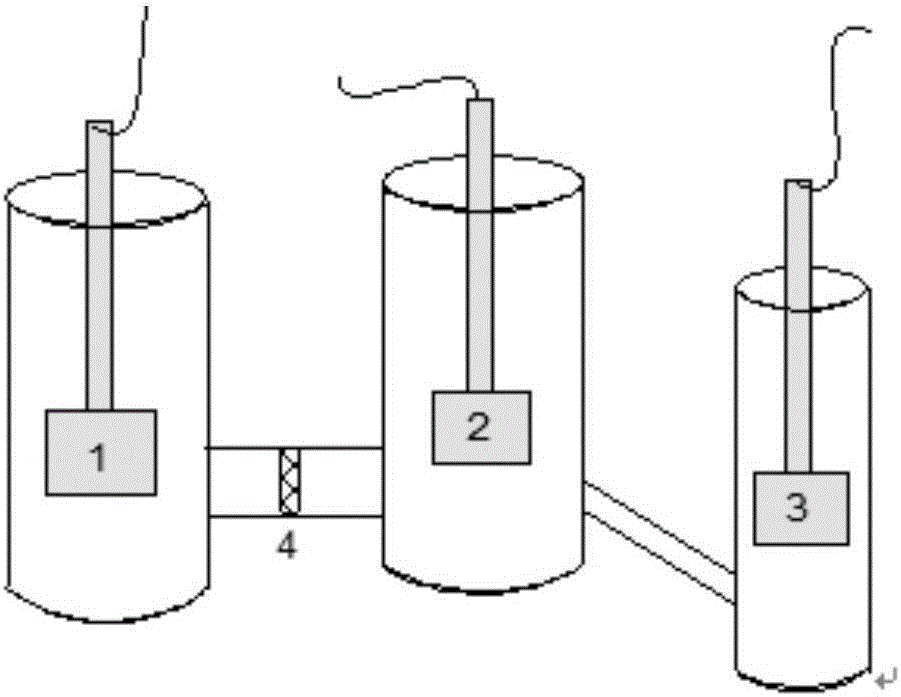

[0040] 2) Hydrothermal synthesis method: add 20mL deionized water into a 50mL beaker, then add 1.1222g, 5.0000g and 8.5714g AMT in turn, stir to dissolve, then add 150mgCNTs, sonicate with an ultrasonic instrument for 20min, transfer to the reaction kettle , No. 1, 2, 3. Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com