A kind of welding method of pure titanium or titanium alloy/carbon steel layered composite plate

A welding method and composite plate technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as differences in chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

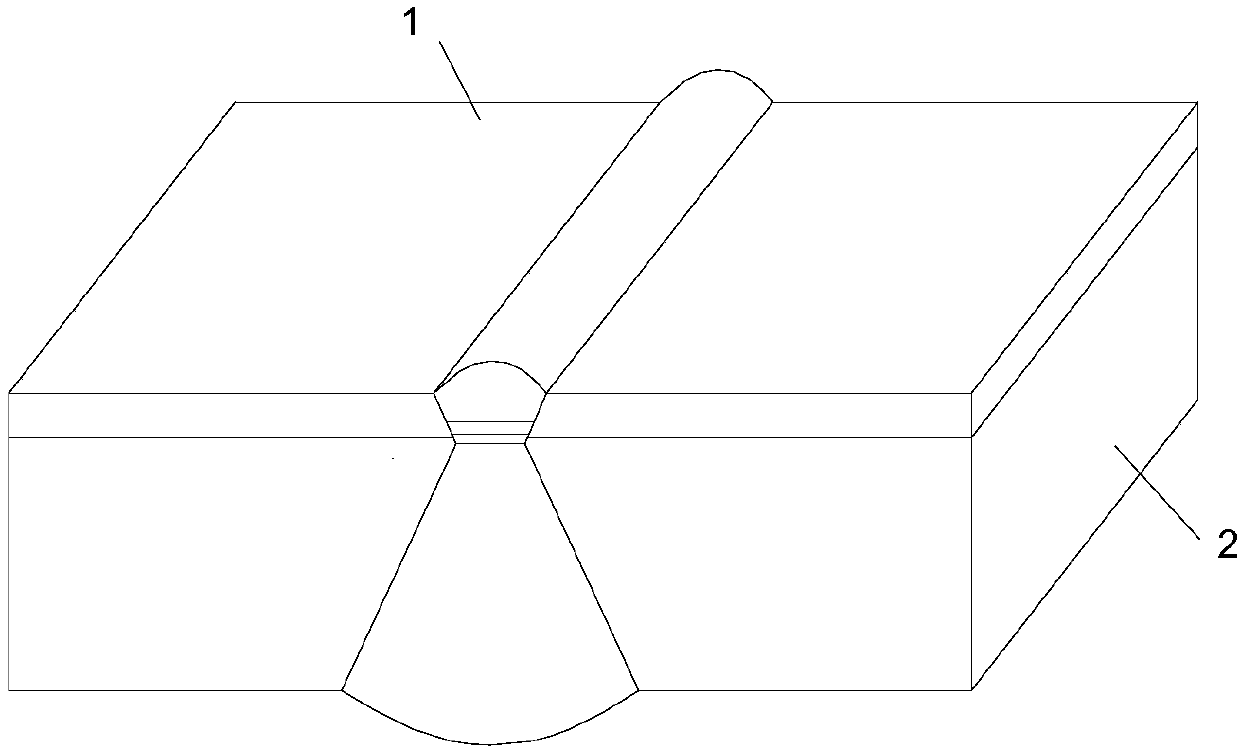

[0031] see figure 1 , taking explosion + hot-rolled TA1 / X65 titanium / pipeline steel clad plate as the welding test plate, in this example, the total thickness of TA1 / X65 titanium / pipeline steel clad plate is 16mm, and the thickness of X65 carbon steel layer 2 side is 14mm, TA1 The thickness of one side of the pure titanium layer 1 is 2mm.

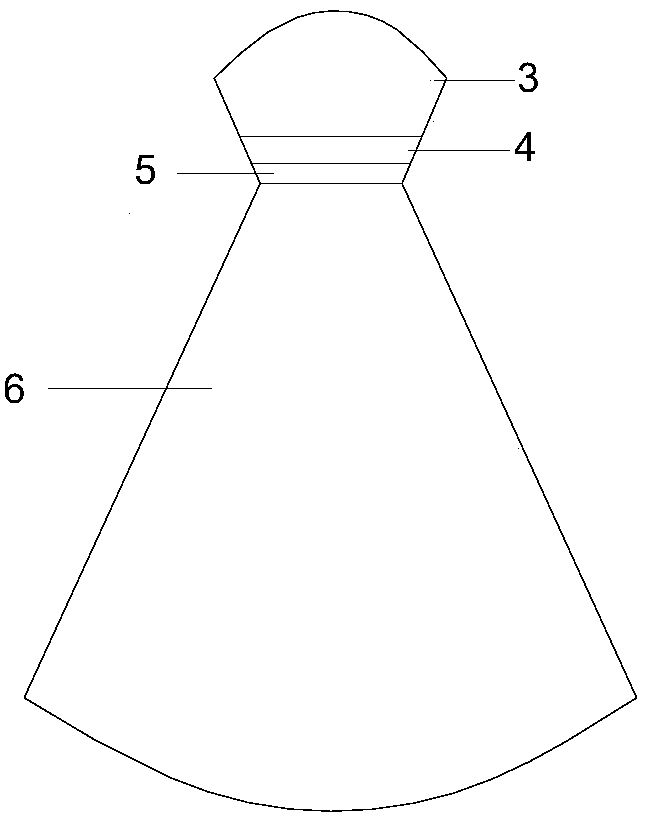

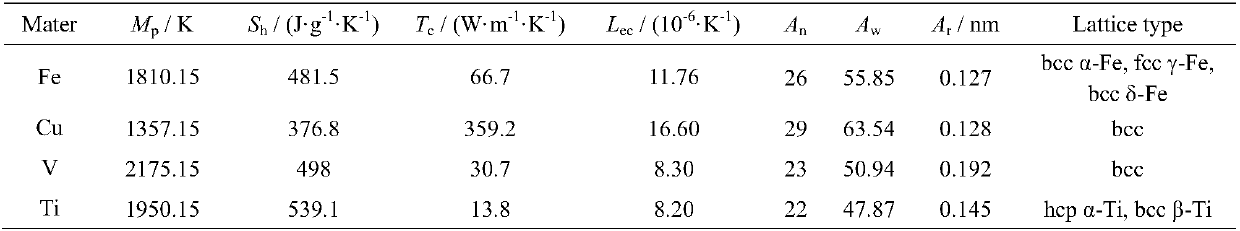

[0032] use Special compound groove design, TA1 pure titanium layer 1 side groove depth is 4~5mm, angle is 60~70°, width is 6~8mm; X65 pipeline carbon steel layer 2 side groove angle is 60~80° °, the width is 16-22mm, and the depth is 11-20mm. Base X65 steel is welded by MAG, using H08Mn2SiA Welding wire to form carbon steel layer deposited metal zone 6; pure Cu cold spray coating 5 (purity≧99.995%), using cold spray technology; pure V cold spray coating 4 (purity≧99.995%), also using cold spray technology; TA1 The pure titanium layer 1 adopts TIG welding, and uses industrial pure titanium (purity≧99.999%) TA1 welding wire To form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com