Clamping claw device for assembling O-shaped ring

An O-ring and clamping jaw technology, applied in the field of clamping jaw devices for O-ring assembly, can solve problems such as low operation efficiency, and achieve the effects of quick installation, compact internal space and small structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

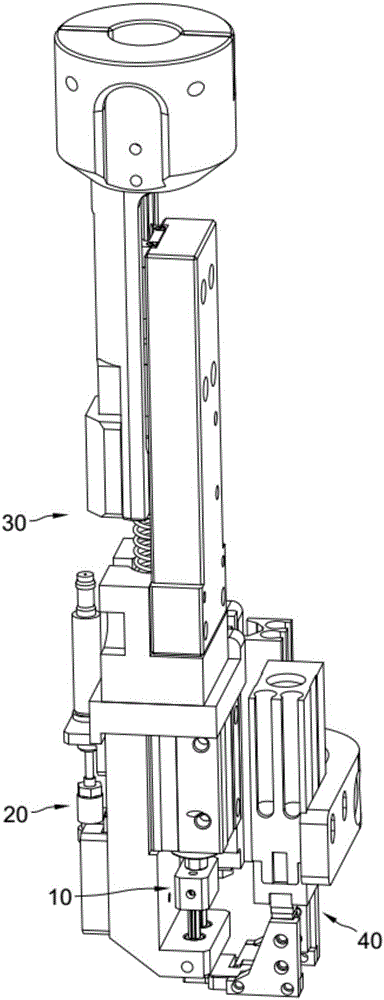

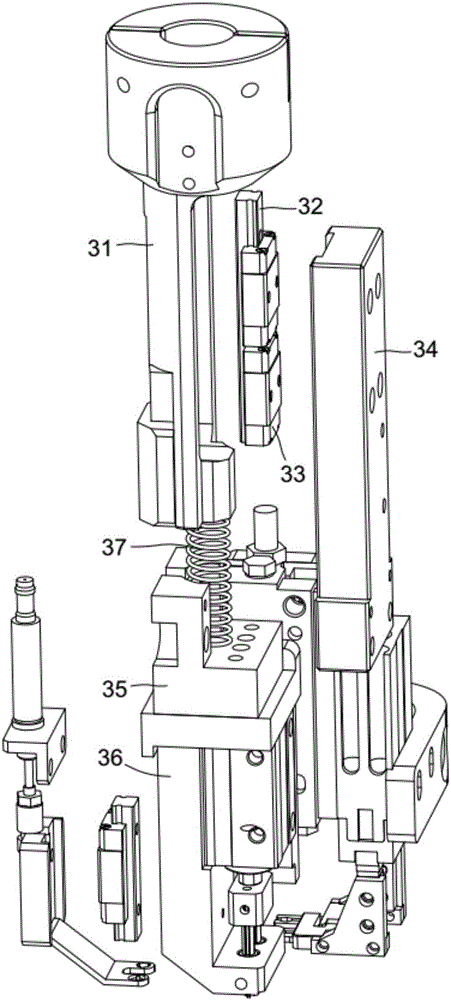

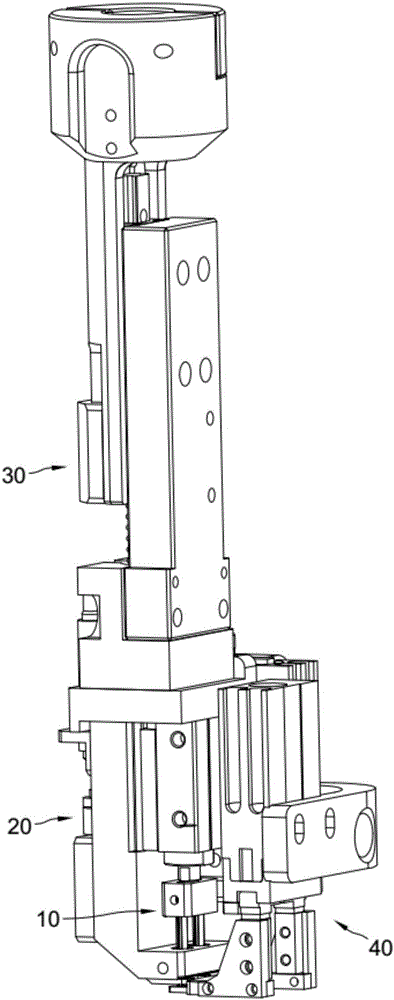

[0033] combine figure 1 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 9 , Figure 10 , a jaw device for O-ring assembly, including a connecting module 30 connected to the motion module, a retrieving module 10 installed on the connecting module, a sleeve module 20 and a clamping module 40, the retrieving module is located in the connecting module Directly below the , the nesting module and the gripping module are located on both sides of the reclaiming module. The retrieving module includes a fixed and elastic retrieving sleeve 11, a retrieving needle 12 inserted in the retrieving sleeve that can be raised and lowered, and the retrieving needle is a pointed object with a small bottom and a large top. Comprising a liftable sleeve 21, the sleeve is provided with a through hole 210 that is matched with the material taking cover. The clamping module includes a liftable jaw cylinder 41, which can push up the O-ring on the pick-up sleeve 11. The lower part of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com