Manufacturing method of mixer truck with concrete storage amount capable of being automatically controlled

一种制造方法、搅拌车的技术,应用在水泥搅拌装置、化学仪器和方法、黏土制备装置等方向,能够解决稳定性差、电能浪费、倾倒不均匀等问题,达到高适应性、减少劳动强度、倾倒混凝土均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

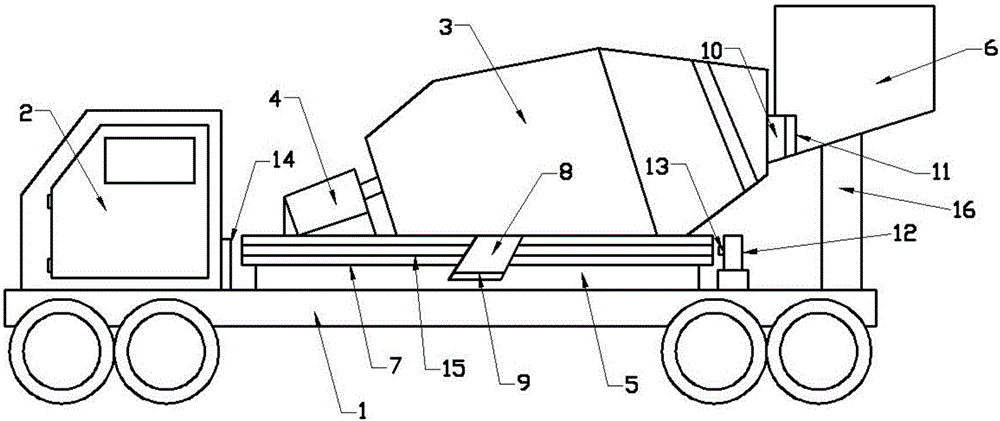

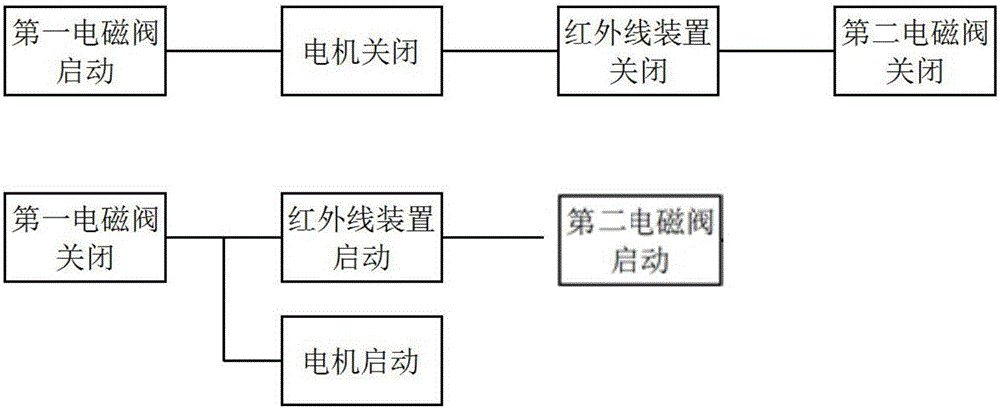

[0024] Example 1: Please refer to the attached drawings. A mixer truck that automatically controls the storage capacity of concrete includes a chassis 1, a control room 2, a mixing barrel 3, a motor 4, and a storage box 6; the chassis 1 is equipped with a control room 2 An elastic device 5 is arranged between the bottom plate 7 and the chassis 1. The elastic device 5 is a leaf spring or is supported by several coil springs, so that the bottom plate 7 can move up and down under the action of the elastic device 5; A through hole 15 connecting the left and right end surfaces of the bottom plate 7 is opened inside. The inner surface of the through hole 15 is polished and polished, and the surface is smooth and easy to reflect; infrared devices are installed on both sides of the bottom plate 7. The infrared device includes infrared emission The infrared transmitter 13 is located at the right end of the bottom plate 7. The infrared transmitter 13 is installed on the adjusting seat 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com