Plastic woven bag automatic cutting bag hot and cold cutter dual-purpose device

A plastic woven bag and dual-purpose device technology, which is applied in packaging, bag making operations, transportation and packaging, etc., can solve the problems of low work efficiency, low precision, and automatic switching between cold cutting and hot cutting, etc., so as to improve work efficiency and reduce costs. Reduced, the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

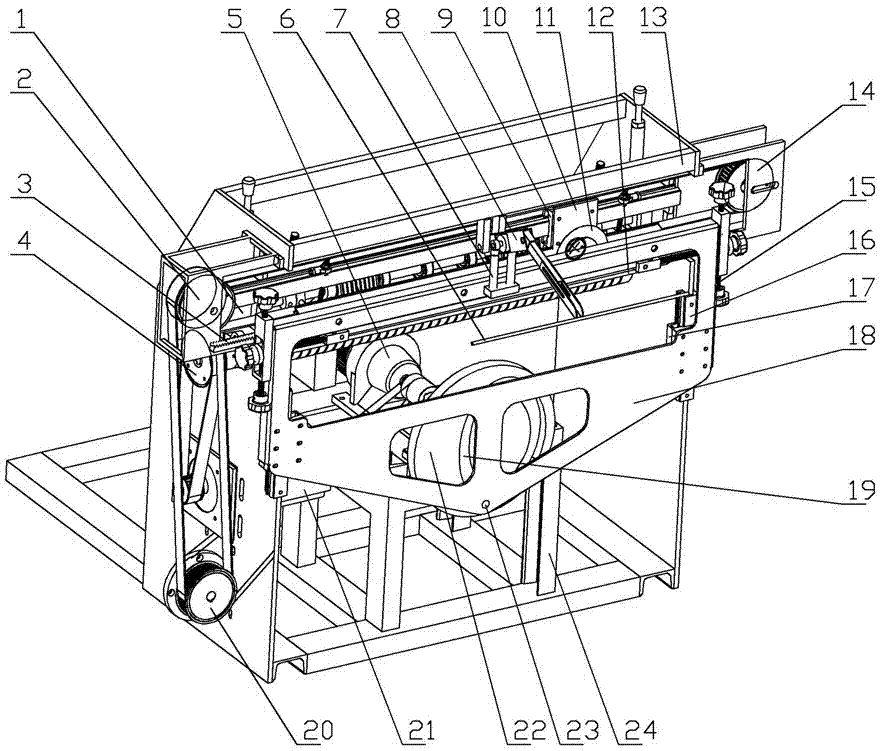

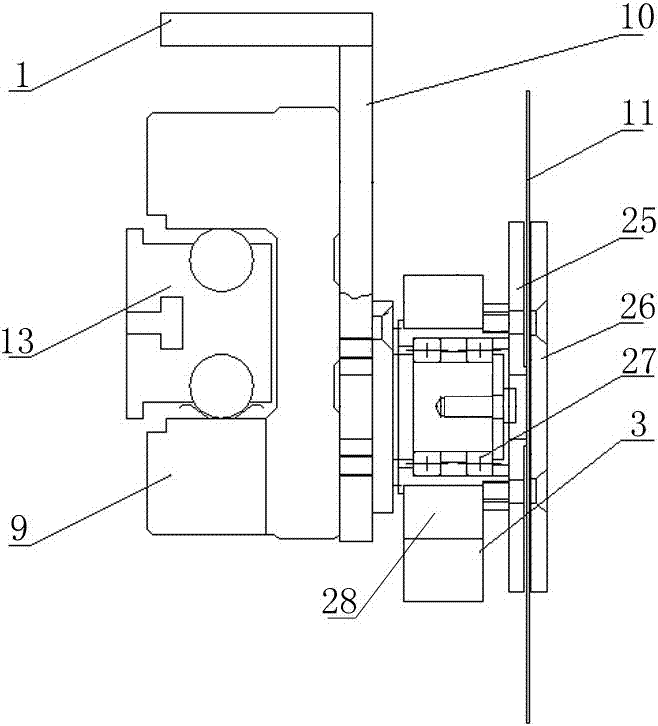

[0019] refer to figure 1 and figure 2 , the present invention includes a main frame 24 with a main rubber roller 4 on the top; one end of the main rubber roller 4 is connected to a servo motor 21 through a belt; the main motor 5 is provided at the bottom of the main frame 24, and the main motor The rotating shaft of 5 is connected with the central transmission of grooved cam 22 inner side by hot knife electromagnetic clutch; The top is provided with a driving wheel 2 and a driven wheel 14 connected horizontally by a synchronous belt 1, and the driving wheel 2 is connected to the belt pulley 20 on one side of the main frame 24 through a belt; The linear guide rail I13 between the driven wheels 14 and corresponding to its level; the linear guide rail I13 is slid with a slider I9 whose top end is fixedly connected with the synchronous belt 1; the slider I9 passes through the connecting plate 10 and the outer bearing The seat 27 is fixedly connected; the bearing seat 27 is rota...

Embodiment 2

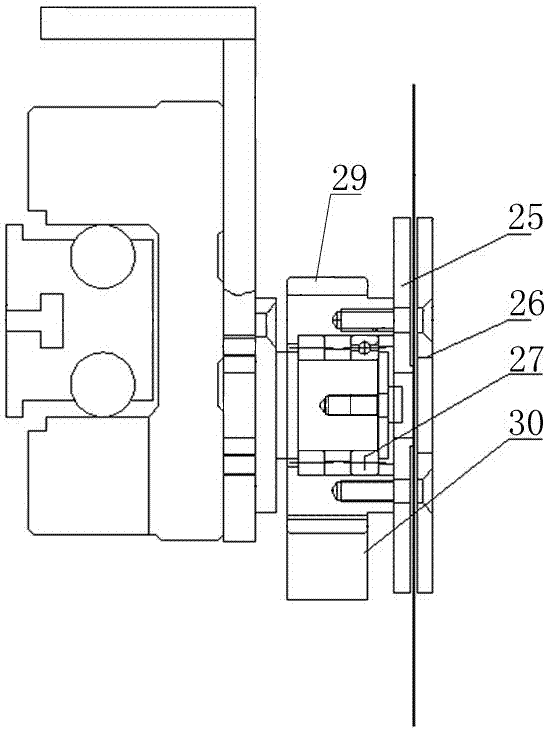

[0023] refer to image 3 Bearing seat 27 among the present invention can be connected with gear 29 in rotation, and gear 29 and the rack 30 that is fixedly connected on the main body frame 24 intermesh transmission connection, and cold-cut circular flying knife 11 is fixedly connected with gear 29; Therefore, gear 29 When doing horizontal movement on the rack 30, it can drive the cold-cut circular flying knife 11 to do horizontal motion and the cold-cut circular flying knife 11 also does circular motion at the same time; Therefore, the linear speed of the cold-cut circular flying knife 11 is much greater than that of the gear 29, and the resistance encountered by the cold-cut circular flying knife 11 during the cutting process is negligible, so there is no need to install a pressure bag Agency, simplified structure.

Embodiment 3

[0025] refer to Figure 4 Bearing block 27 among the present invention can be connected with synchronous wheel 31 rotations, and synchronous wheel 31 and synchronous belt 32 are meshed transmission connection; The horizontal motion is done under the transmission connection, and the cold-cut circular flying knife 11 is fixedly connected with the synchronous wheel 31, and its diameter is larger than that of the synchronous wheel 31; Speed, the resistance encountered by the cold-cut circular flying knife 11 in the cutting process can be ignored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com