Multifunctional printing machine

A printing machine and multi-functional technology, which is applied in the field of multi-functional printing machines, can solve the problems of unsatisfactory PCB board printing and transportation difficulties, achieve the effect of convenient printing of PCB board through holes, improve production quality, and solve the effect of printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

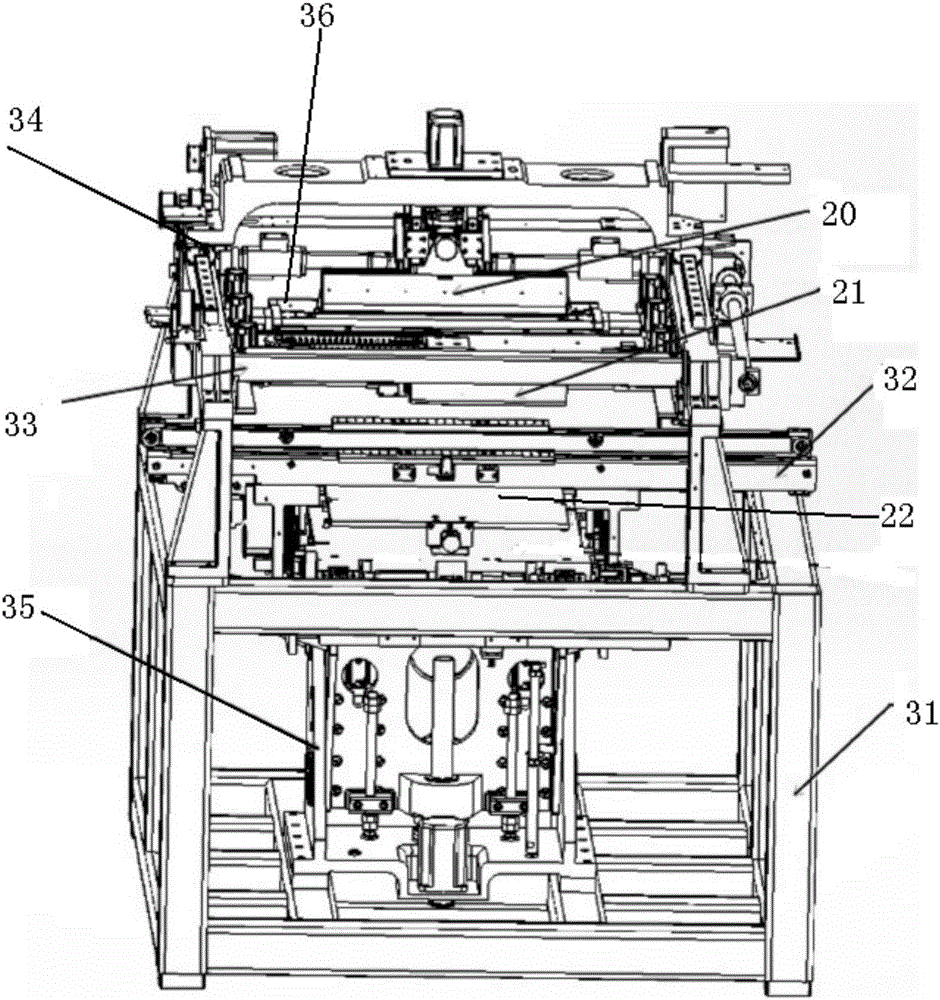

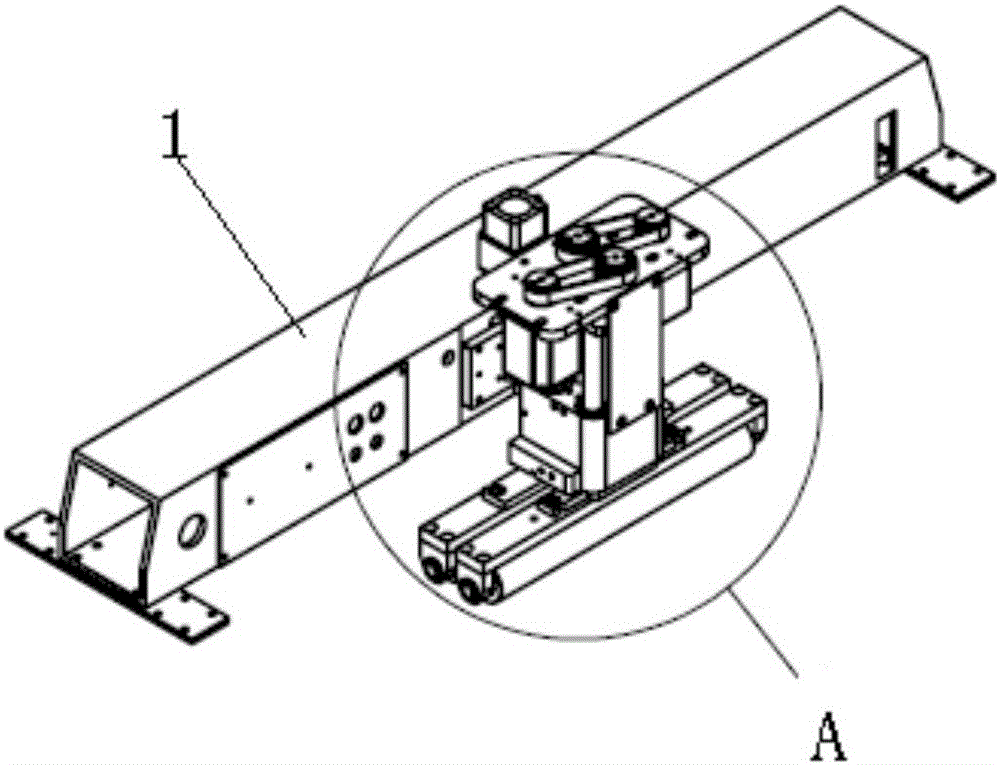

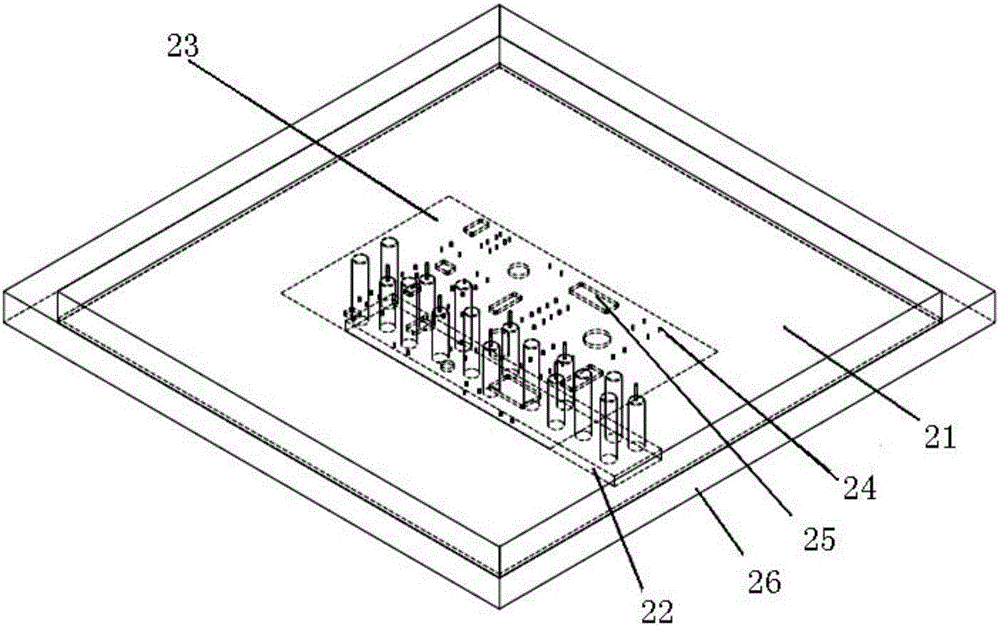

[0034] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a multifunctional printing machine includes a frame 31, which is provided with an adjustable conveying track device 32 for conveying products and can adjust the height position according to the thickness of the product, and the adjustable conveying track device 32 is directly above A steel mesh moving device 33 is provided, and a scraper moving control device 34 is arranged directly above the steel mesh moving device 33. The steel mesh moving device 33 controls a steel mesh 21 with a middle groove, and the scraper moving control device 34 controls a flexible scraper Just below the head 20, the adjustable conveying track device 32 is provided with a product lifting device 35 that jacks up the products on the adjustable conveying track device 32. The product lifting device 35 is provided with a top PING structure 22, and the adjustable conveying track device 32 After the product is ...

Embodiment 2

[0062]Embodiment 2: A kind of multifunctional printing machine, comprises frame 31, is provided with on the frame 31 and is used for conveying product, and can adjust the height position according to product thickness adjustable conveying track device 32, the front and right sides of adjustable conveying track device 32 A steel mesh moving device 33 is provided above, and a scraper moving control device 34 is arranged directly above the steel mesh moving device 33. The steel mesh moving device 33 controls a flat steel mesh 21, and the scraper moving control device 34 controls a rigid scraper head. , just below the adjustable conveying track device 32 is provided with a product lifting device 35 that will jack up the product on the adjustable conveying track device 32, and a top PING structure 22 is provided on the product lifting device 35, and the adjustable conveying track device 32 After the product is transported from the adjustable conveying track device 32 to the designat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com