Automatic pulp feeding system for flat screen printing machine

A flat screen printing and automatic technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problem of adding too much or too little slurry, and achieve the effect of avoiding too much or too little

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

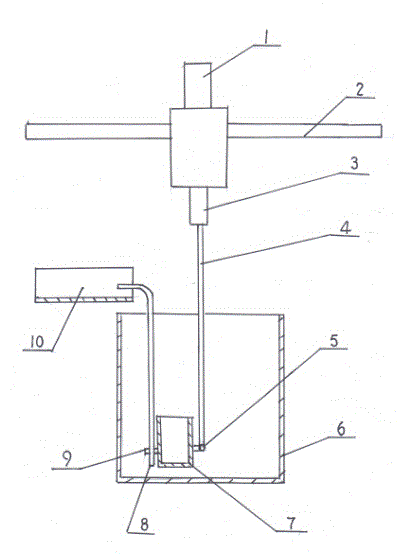

[0006] The present invention will be described in detail below in conjunction with the accompanying drawings: the longitudinal movement guide rail 2 of the manipulator is installed above the side of the flat screen printing machine, parallel to the length direction of the flat screen printing machine, the longitudinal movement of the manipulator is driven by a motor, and the vertical movement of the manipulator is up and down. Driven by a cylinder or a motor 1, the manipulator head 3 is equipped with an electromagnet, and a hinge 5 is installed on the outer edge of the lifting hopper 7 at a height greater than 1 / 2, on which a lifting rod 4 is hinged, and is fixed on the opposite side of the hinge 5 The small ring 9 of slit is arranged, and the material of small ring 9 is elastic, and guide rod 8 is sleeved in the small ring 9, and the arc bending of 90° angle is formed above the guide rod 8, because small ring 9 is slit and It is flexible, so it can be easily taken out or put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com