Front axle assembly of automobile drum brake

A drum brake and front axle assembly technology, applied in the direction of brakes, brake components, axles, etc., can solve the problems of steering knuckle lubrication and sealing parts, lack of lightweight design, poor lubrication effect, etc., to reduce The effect of tooling input, weight reduction, and overall weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

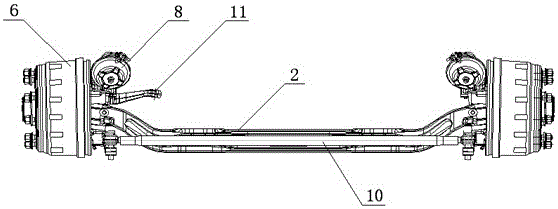

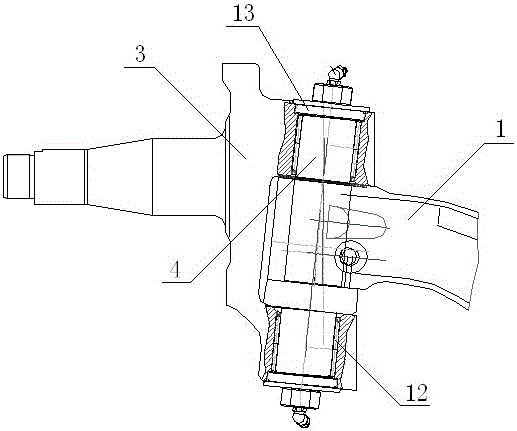

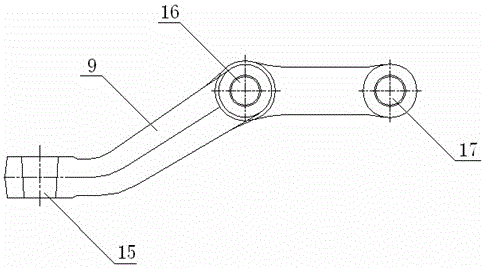

[0028] see Figure 1 to Figure 11 , a kind of automobile drum brake front axle assembly of the present invention, comprises front axle 1, and the installation hole of front axle 1 two ends is respectively connected with steering knuckle 3 through main pin 4, and brake is installed on the installation shaft outside steering knuckle 3 The hub 5 and the brake hub 5 are respectively equipped with a brake drum 6 and a brake assembly 7, and the brake assembly 7 is connected with the brake chamber 8. It is characterized in that: the web of the front axle 1 is provided with a A plurality of hollow holes 2, the two ends of the kingpin holes of the upper and lower lugs of the steering knuckle 3 are provided with internal threads, the kingpin oiling screw plug 13 is connected with the steering knuckle 3 through the threads, and the kingpin oilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com