Textile bobbin

A textile drum and bobbin technology, applied in the textile field, can solve the problems of troublesome finishing, easy to roll around, increase the workload, etc., and achieve the effect of saving space and placing it horizontally and stably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

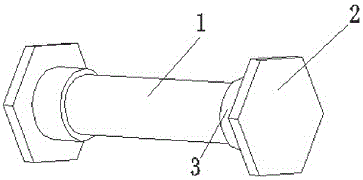

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

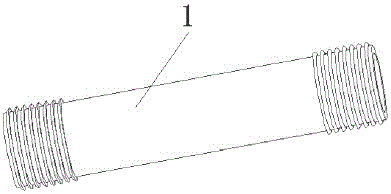

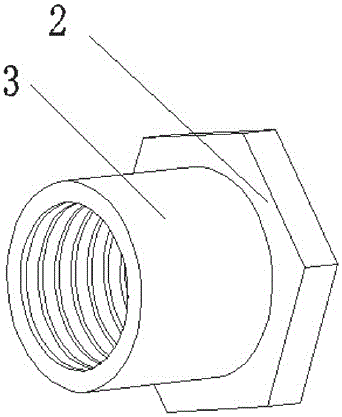

[0013] As shown in the figure, the textile bobbin includes an aluminum alloy inner tube 1 and an aluminum alloy side plate 2, the aluminum alloy side plate 2 is screwed to both ends of the aluminum alloy inner tube 1, and the aluminum alloy side plate 2 is a regular polygon. When the aluminum alloy inner tube 1 is wound with the spinning thread and needs to be stored, the aluminum alloy side plate 2 is put on; when the aluminum alloy inner tube 1 is not wrapped with the spinning thread, the aluminum alloy side plate 2 is removed, This saves space. The aluminum alloy side plate 2 becomes a regular polygon, which makes it more stable to be placed horizontally and will not roll arbitrarily.

[0014] The specific connection structure of the aluminum alloy inner tube 1 and the aluminum alloy side plate 2 is as follows: the two ends of the aluminum alloy inner tube 1 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com