Vertical prefabricating construction method of cooling tower herringbone column

A construction method and cooling tower technology, applied in refrigeration plants, industrial buildings, building structures, etc., can solve problems such as failure to meet fair-faced concrete standards, difficulty in concrete treatment, deviation of steel bar protection layer, etc., and save erection time and formwork Easy to install and reduce the effect of construction site

Inactive Publication Date: 2016-07-27

中能建建筑集团有限公司

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cast-in-place and horizontal prefabricated herringbone columns often have common quality problems such as honeycomb, pockmarked surface, pores, grout leakage, structural cracks, color difference between yi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

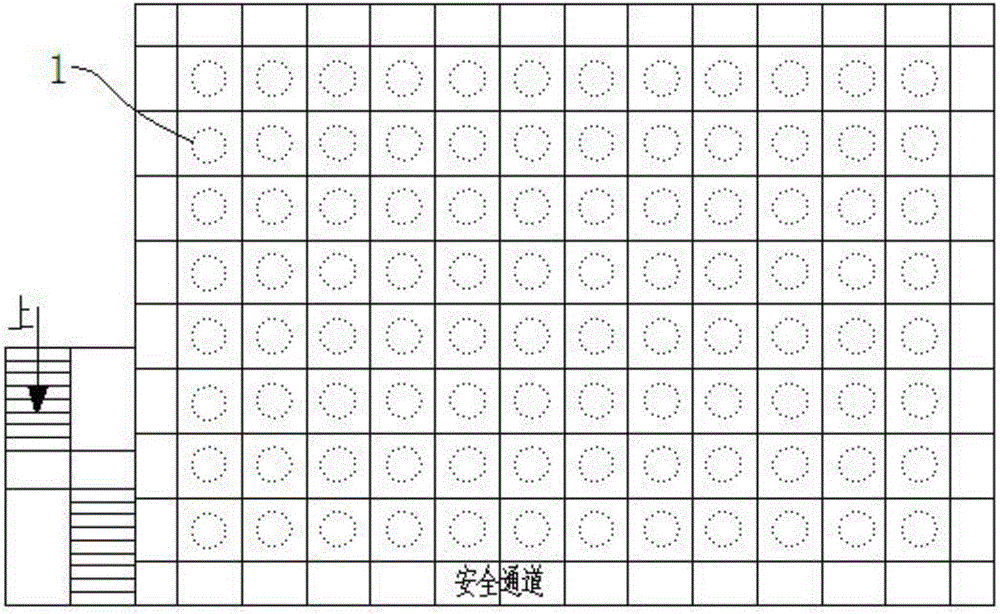

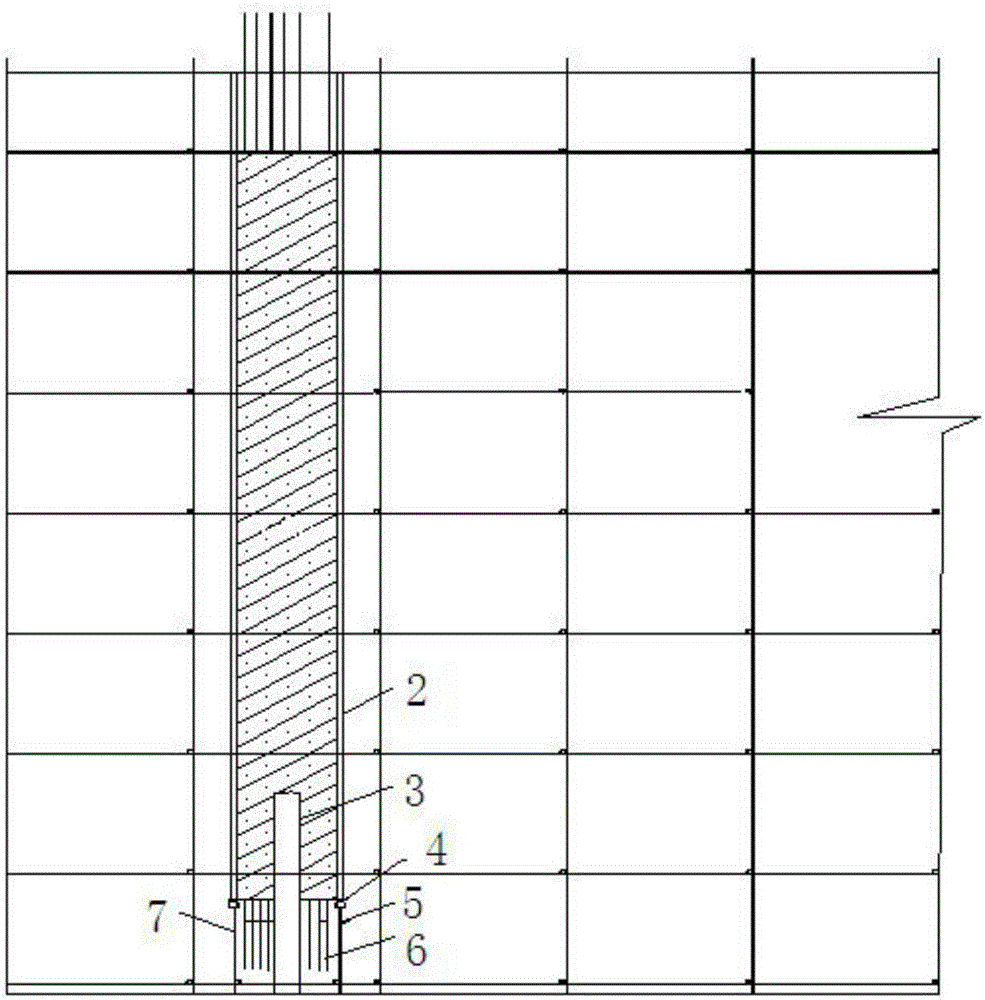

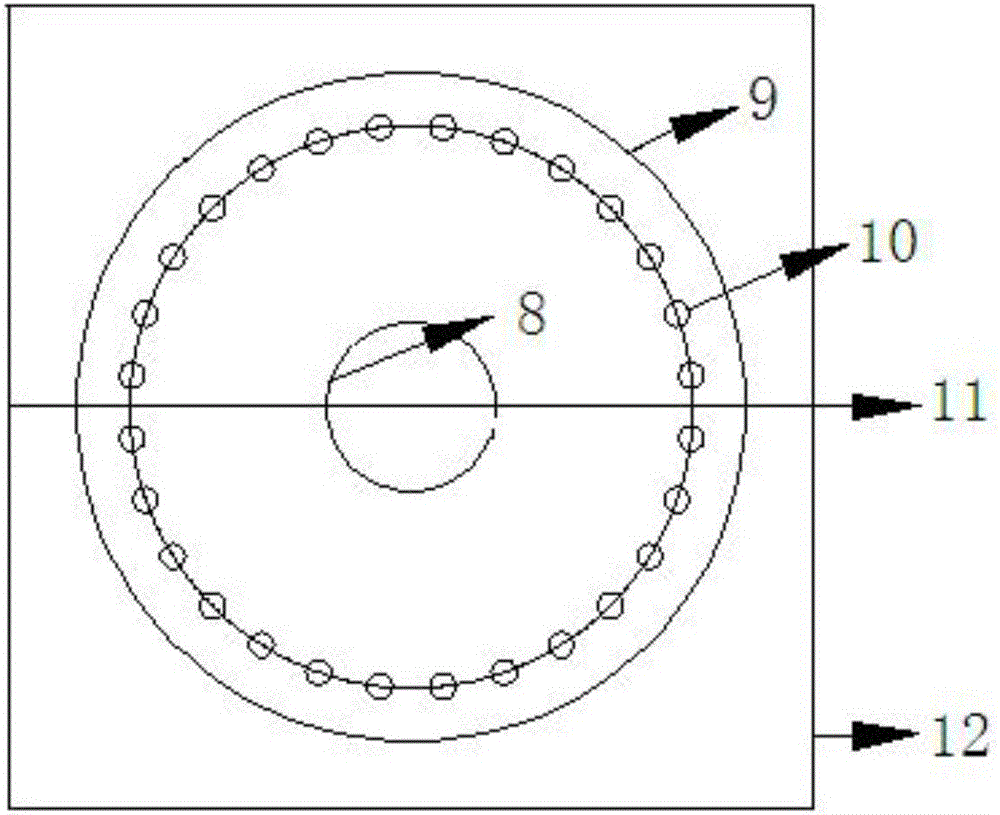

The invention discloses a vertical prefabricating construction method of a cooling tower herringbone column.The method sequentially includes following processes: flattening and hardening a prefabricating yard; setting up a scaffold; mounting a formwork base; making rebars; binding the rebars; making a formwork; mounting the formwork; pouring concrete; demounting the formwork; maintaining the concrete.By using the method, prefabricating can be advanced, and construction period is shortened; the formwork can be quickly circulated and is convenient to mount, and progress is accelerated; number of formworks needing to be purchased is small, cost is saved, and the method is economical and applicable; a rebar cage is vertically mounted, so that accuracy of a position is easy to control and quality of the herringbone column is guaranteed.The method has the advantages of attractive appearance, saving of materials, high construction speed and good economic benefit.

Description

technical field [0001] The invention belongs to the field of engineering construction, and relates to a construction method, in particular to a vertical prefabrication construction method of a cooling tower's herringbone column. Tense cooling tower projects. Background technique [0002] At present, in addition to the cast-in-place construction technology, prefabrication construction technology is also used in the construction of the herringbone column of the hyperbolic cooling tower. Prefabrication is divided into two types: horizontal prefabrication and vertical prefabrication. Cast-in-place and horizontal prefabricated herringbone columns often have common quality problems such as honeycomb, pockmarked surface, pores, grout leakage, structural cracks, color difference between yin and yang, lateral bending, and deviation of steel protection layer on the concrete surface. It is difficult to deal with concrete appearance quality defects and cannot Reach the fair-faced concr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04H5/12E04G21/00

CPCE04H5/12E04G21/00

Inventor 梁君张军有吕少新顾客陈尚文胡兵

Owner 中能建建筑集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com